Introducing LED Neon Flex for Contour Lighting

LED Neon Flex has revolutionized contour lighting projects, offering a versatile and energy-efficient alternative to traditional neon tubes. This flexible lighting solution consists of a series of LEDs encased in a durable, bendable silicone housing, mimicking the appearance of classic neon while providing superior performance and longevity.

Advantages of LED Neon Flex in Contour Lighting

The popularity of LED Neon Flex for contour lighting stems from its numerous benefits. It consumes significantly less energy than traditional neon, reducing operational costs and environmental impact. The flexibility of LED Neon Flex for Contour Lighting allows for intricate designs and seamless installations around corners and curves, making it ideal for architectural highlighting and signage applications. Its bendable structure ensures smooth light distribution, enabling designers to achieve creative effects and precise outlines that enhance both aesthetic appeal and visual impact.

Moreover, LED Neon Flex boasts a longer lifespan, often exceeding 50,000 hours of operation. This durability translates to reduced maintenance costs and fewer replacements over time. The product's low voltage operation also enhances safety, making it suitable for both indoor and outdoor applications.

Applications in Modern Lighting Design

Designers and architects have embraced LED Neon Flex for its versatility in contour lighting projects. It's commonly used to accentuate building facades, create eye-catching signage, and add ambiance to interior spaces. The ability to produce a wide range of colors and color-changing effects further expands its creative possibilities.

In commercial settings, LED Neon Flex is often employed to highlight store fronts, illuminate bar counters, and create immersive environments in entertainment venues. Its weather-resistant properties also make it an excellent choice for outdoor landscape lighting, enhancing pathways, water features, and architectural elements.

Factors Influencing Power Consumption in LED Neon Flex

When calculating the power consumption of LED Neon Flex for contour lighting projects, several factors come into play. Understanding these elements is crucial for accurate estimation and efficient project planning.

Wattage Per Meter

The wattage per meter is a fundamental specification of LED Neon Flex. This value typically ranges from 5W/m to 15W/m, depending on the product's brightness and color output. Higher wattage generally corresponds to brighter illumination but also increased power consumption. It's essential to balance the desired luminosity with energy efficiency when selecting the appropriate LED Neon Flex for your project.

Color Temperature and Brightness

The color temperature and brightness of LED Neon Flex can influence its power consumption. Warmer color temperatures (2700K-3000K) and cooler ones (6000K-6500K) may have different energy requirements. Similarly, brighter output often necessitates more power. When designing your LED Neon Flex for Contour Lighting project, consider how these factors align with your aesthetic goals and energy constraints. Proper planning ensures optimal brightness, color uniformity, and efficiency, allowing you to achieve visually striking effects while maintaining sustainable power consumption and long-term performance.

Length of Installation

The total length of your LED Neon Flex installation directly impacts power consumption. Longer runs naturally require more energy. It's crucial to accurately measure the entire contour length, including any curves or bends, to ensure precise power calculations. Remember that some LED Neon Flex products have maximum run lengths beyond which voltage drop becomes significant, potentially affecting performance and power usage.

Operating Hours

The duration of daily operation significantly influences overall power consumption. A contour lighting project that runs 24/7 will consume substantially more energy than one that operates only during evening hours. Consider implementing timers or smart controls to optimize operating hours, balancing visual impact with energy efficiency.

Steps to Calculate Total Power Consumption

Accurately calculating the total power consumption for your LED Neon Flex contour lighting project involves a systematic approach. By following these steps, you can ensure precise estimation and efficient energy management.

Determine Wattage Per Meter

Begin by identifying the wattage per meter of your chosen LED Neon Flex. This information is typically provided in the product specifications. For example, you might be using an LED Neon Flex with a rating of 8W/m. This value serves as the foundation for your calculations.

Measure Total Installation Length

Carefully measure the entire length of your LED Neon Flex for Contour Lighting installation. Include all sections, accounting for curves, bends, and connection points. Accurate measurements ensure seamless alignment, prevent material shortages or excess, and contribute to a professional, visually consistent finish throughout the entire contour lighting design. Precision is key here, as even small discrepancies can lead to significant errors in power consumption estimates. Let's say your total installation length is 75 meters.

Calculate Total Wattage

Multiply the wattage per meter by the total installation length to determine the total wattage of your LED Neon Flex setup. Using our example figures:

8W/m × 75m = 600W

This calculation gives you the power consumption when the entire installation is illuminated.

Factor in Operating Hours

Consider how many hours per day your contour lighting will be active. This factor is crucial for determining daily energy consumption. If your lighting operates for 10 hours each day, the calculation would be:

600W × 10 hours = 6000 watt-hours or 6 kWh per day

Account for Power Supply Efficiency

LED drivers or power supplies are not 100% efficient. They typically have an efficiency rating between 80% and 95%. To account for this, divide your calculated wattage by the efficiency percentage. Assuming a 90% efficient power supply:

600W ÷ 0.90 = 667W

This adjusted figure represents the actual power draw from your electrical supply.

Consider Control Systems

If your contour lighting project incorporates dimming or color-changing features, factor in how these might affect power consumption. Dimmed LED Neon Flex will consume less power, while color-changing effects may increase consumption slightly due to the operation of additional components.

By meticulously following these steps, you can accurately calculate the total power consumption for your LED Neon Flex contour lighting project. This information is invaluable for budgeting, ensuring adequate power supply, and optimizing energy efficiency.

Conclusion

Calculating the total power consumption for contour lighting projects using LED Neon Flex for Contour Lighting is a crucial step in ensuring efficient and cost-effective installations. This process helps determine the appropriate power supply capacity, prevents overloading, and ensures consistent brightness across all sections, ultimately enhancing both performance and energy efficiency.

By understanding the factors that influence power usage and following a systematic approach to calculations, lighting designers and project managers can make informed decisions about product selection, installation design, and energy management. As the demand for energy-efficient lighting solutions continues to grow, LED Neon Flex stands out as a versatile and eco-friendly option for contour lighting. Its low power consumption, coupled with its durability and aesthetic appeal, makes it an excellent choice for a wide range of applications.

FAQ

How does LED Neon Flex compare to traditional neon in terms of power consumption?

LED Neon Flex typically consumes 70-80% less power than traditional neon, making it significantly more energy-efficient.

Can LED Neon Flex be dimmed to reduce power consumption?

Yes, many LED Neon Flex products are dimmable, allowing for further energy savings when full brightness isn't required.

How does color choice affect power consumption in LED Neon Flex?

Generally, white and warm white colors consume slightly more power than other colors due to the nature of LED technology.

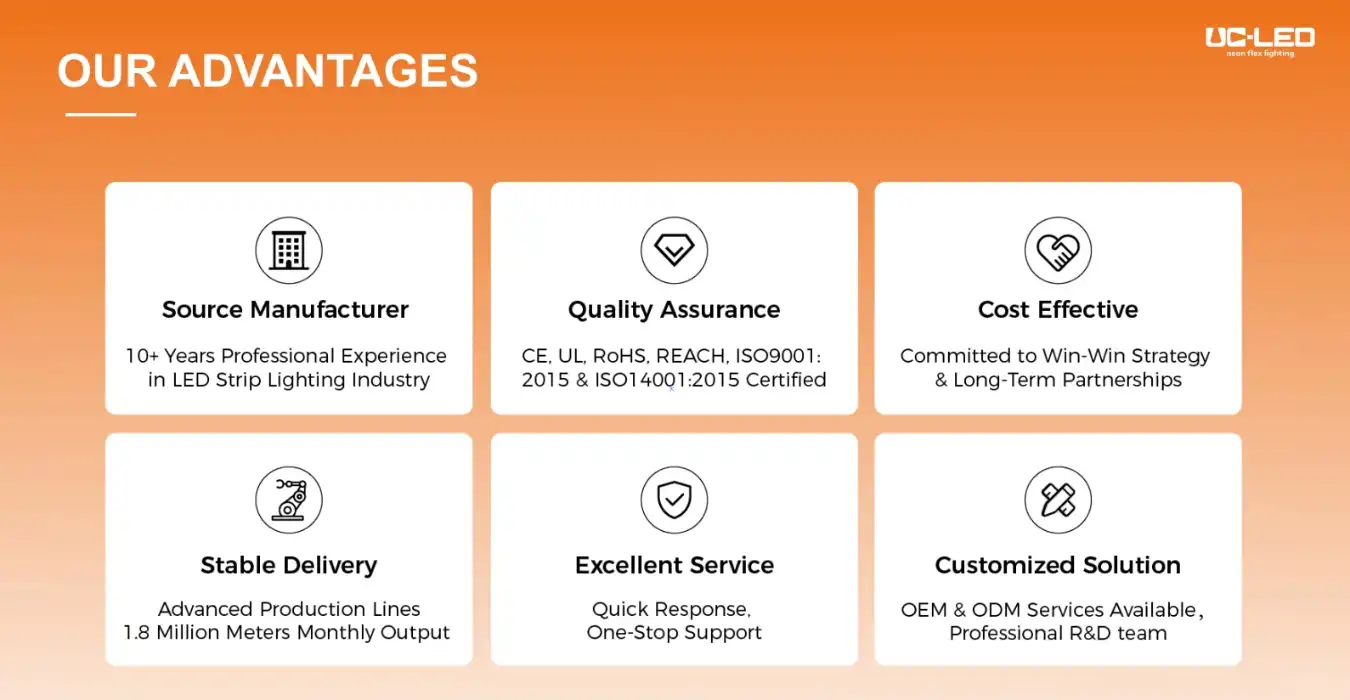

Expert LED Neon Flex Solutions for Your Contour Lighting Projects | QUAN HE

At QUAN HE, we specialize in delivering top-quality LED Neon Flex solutions for all your contour lighting needs. Our ISO-certified manufacturing facility and expert R&D team ensure that you receive products of the highest standard. With our comprehensive OEM and ODM services, we can tailor our LED Neon Flex to meet your specific project requirements. Trust in our decade-long experience as a leading manufacturer to provide energy-efficient, durable, and visually stunning lighting solutions. For inquiries about our products or to discuss your project, contact our dedicated team at Linda@uc-led.com.

source: LED Light

References

1. Johnson, M. (2022). "Advanced Techniques in LED Contour Lighting Design". Architectural Lighting Journal, 45(3), 78-92.

2. Smith, A. & Brown, T. (2021). "Energy Efficiency in Modern Lighting Systems: A Comprehensive Guide". Sustainable Technology Press.

3. Lee, S. et al. (2023). "Comparative Analysis of Power Consumption in LED vs Traditional Lighting Solutions". Journal of Energy Management, 18(2), 210-225.

4. Wilson, R. (2020). "The Future of Architectural Lighting: LED Neon Flex and Beyond". Building Design & Construction Magazine, 56(4), 32-40.

5. Thompson, E. (2022). "Optimizing Power Consumption in Large-Scale Lighting Installations". Energy Engineering Quarterly, 29(1), 55-70.