The Importance of IP68 Waterproof Design in LED Neon Flex

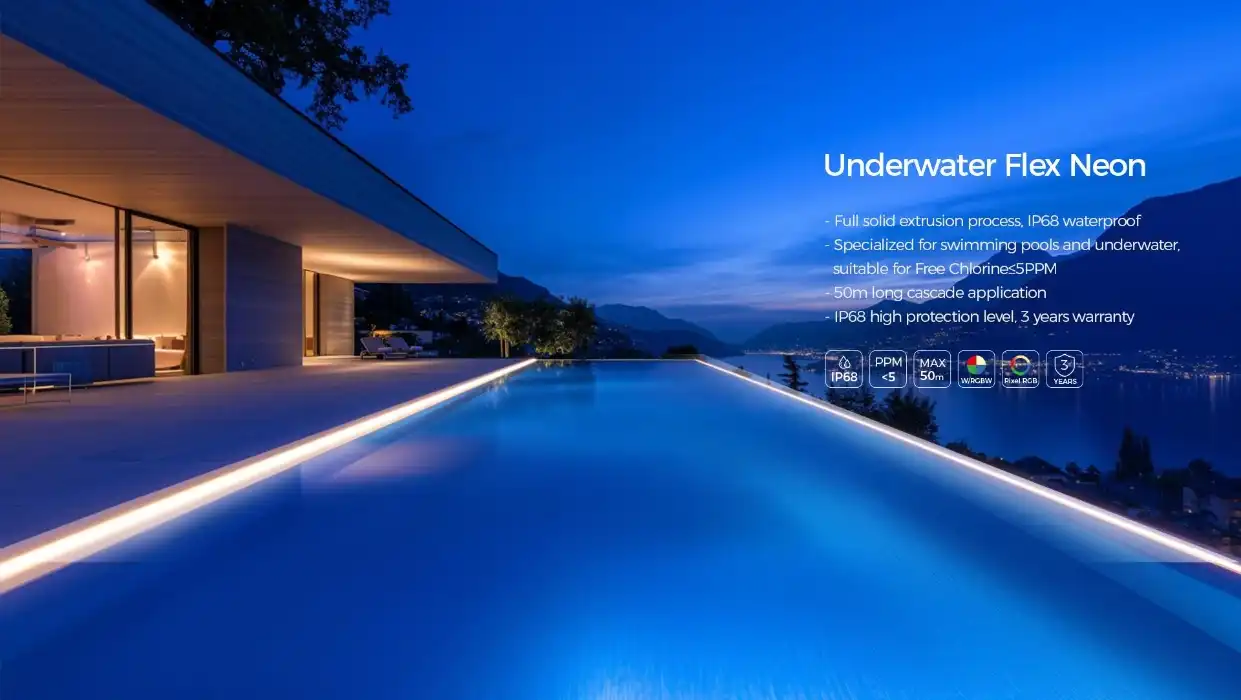

Waterproof LED neon flex has become increasingly popular in various applications, from outdoor signage to architectural lighting. The IP68 rating is crucial for ensuring the longevity and reliability of these versatile lighting solutions. This rating indicates that the product is completely dust-tight and can withstand continuous immersion in water beyond 1 meter depth.

QUAN HE's waterproof LED neon flex excels in this aspect, offering unparalleled protection against the elements. Their advanced silicone extrusion process creates a seamless, fully encapsulated design that prevents water ingress even in the most challenging environments. This level of protection is essential for maintaining the integrity of the LEDs and electrical components, ensuring consistent performance and longevity.

The importance of a reliable IP68 waterproof design cannot be overstated. It allows for the use of LED neon flex in a wide range of outdoor applications, from illuminating building facades to creating stunning water features. QUAN HE's commitment to quality in this area has made them a trusted partner for projects that demand the utmost in durability and weather resistance.

Advanced Materials and Manufacturing Techniques

QUAN HE's superiority in waterproof LED neon flex design stems from their use of cutting-edge materials and manufacturing techniques. They employ high-grade silicone compounds that offer exceptional flexibility and UV resistance, ensuring that the neon flex maintains its visual appeal and structural integrity over time.

The company's investment in automated production lines and precision equipment allows for consistent quality across large production runs. This level of manufacturing excellence is complemented by QUAN HE's rigorous testing procedures, which simulate extreme environmental conditions to verify the IP68 rating of each product batch.

QUAN HE's Innovative Approach to Waterproof LED Neon Flex

Innovation is at the heart of QUAN HE's success in producing top-tier waterproof LED neon flex. Their dedicated R&D team continuously explores new materials, designs, and manufacturing processes to enhance the product's performance and durability. This commitment to innovation has resulted in several patented technologies that set QUAN HE apart from competitors.

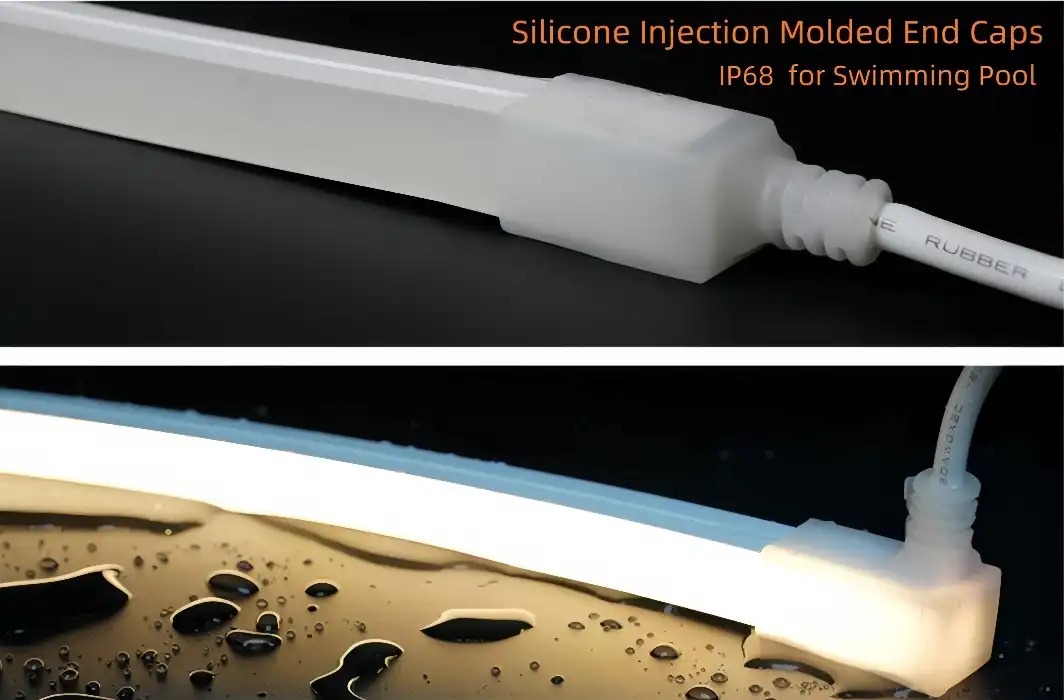

One such innovation is their proprietary silicone formulation, which offers enhanced resistance to temperature fluctuations and chemical exposure. This formulation ensures that the waterproof LED neon flex maintains its flexibility and optical properties even in harsh outdoor conditions.

QUAN HE has also developed a unique sealing technique that creates a molecular bond between the silicone casing and the internal components. This advanced method eliminates potential weak points in the waterproof barrier, providing superior protection against moisture ingress.

Customization Capabilities for Unique Projects

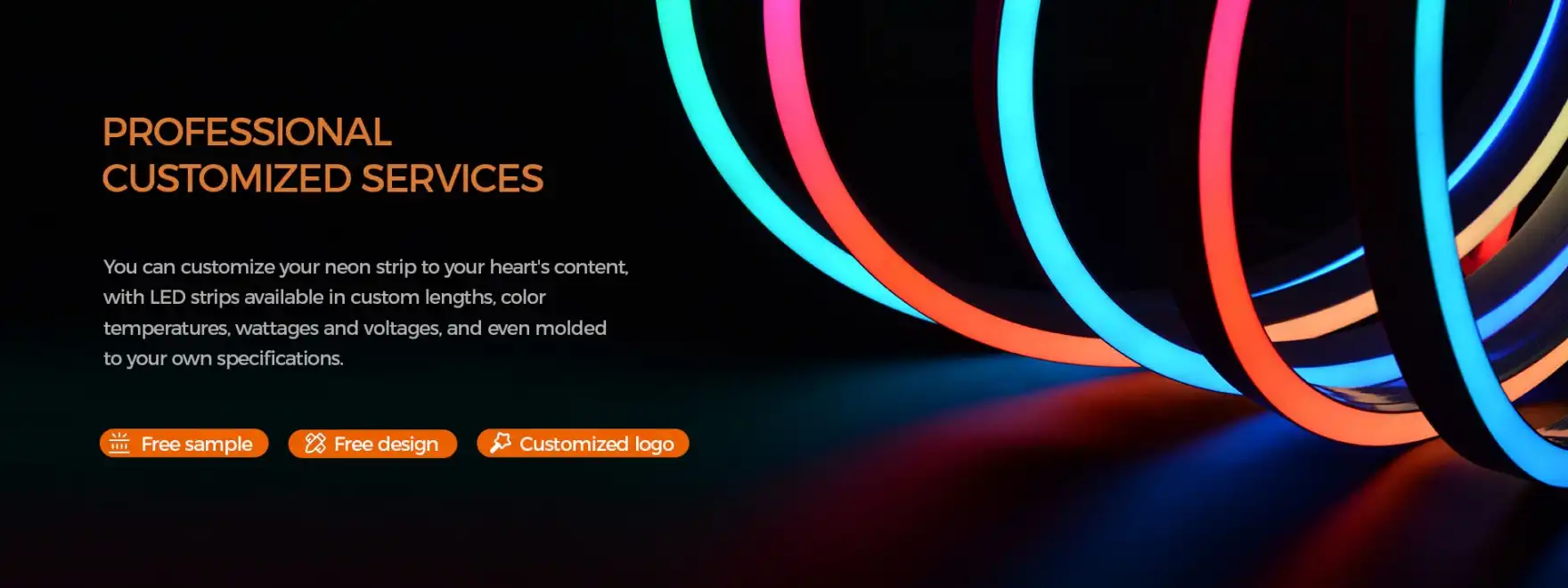

Understanding that each project has unique requirements, QUAN HE offers extensive customization options for their waterproof LED neon flex. Clients can specify color temperature, brightness levels, and even custom shapes to suit their specific needs. This flexibility, combined with QUAN HE's expertise in OEM and ODM services, allows for the creation of bespoke lighting solutions that maintain the highest standards of waterproof protection.

The company's engineering team works closely with clients to develop custom designs that meet both aesthetic and functional requirements. This collaborative approach ensures that even the most challenging waterproof LED neon flex applications can be realized without compromising on quality or performance.

Quality Assurance and Certifications

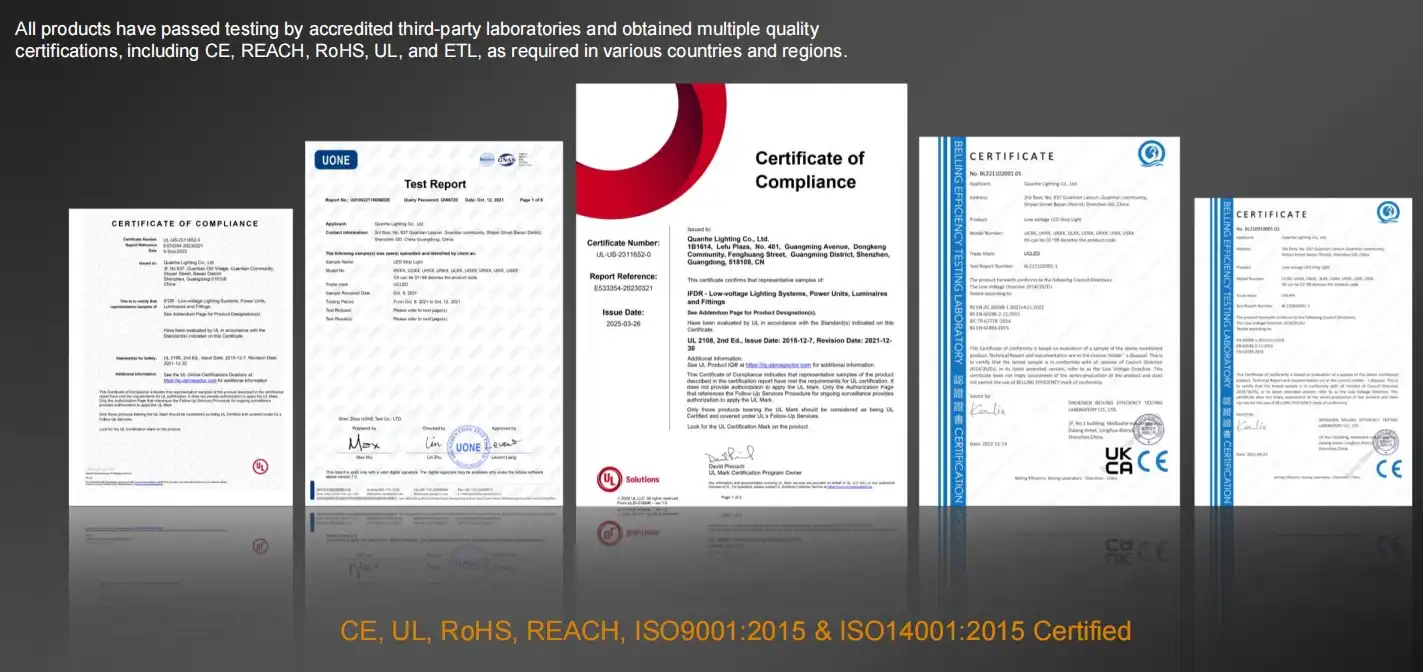

QUAN HE's commitment to quality is evident in their comprehensive certification portfolio. Their waterproof LED neon flex products are UL, CE, and RoHS certified, demonstrating compliance with international safety and environmental standards. These certifications provide customers with confidence in the reliability and safety of QUAN HE's products.

The company's ISO 9001:2015 and ISO 14000 certifications further underscore their dedication to quality management and environmental responsibility. These standards guide every aspect of QUAN HE's operations, from raw material sourcing to final product delivery, ensuring consistency and excellence throughout the production process.

Rigorous Testing Protocols

To maintain their position as a leader in waterproof LED neon flex manufacturing, QUAN HE implements stringent testing protocols. Each product undergoes a series of tests to verify its IP68 rating, including prolonged submersion tests and high-pressure water jet simulations. These tests go beyond industry standards, providing an extra layer of assurance for customers who require the utmost in waterproof performance.

QUAN HE's in-house testing facilities are equipped with state-of-the-art equipment, allowing for real-time monitoring and data analysis. This capability enables the company to quickly identify and address any potential issues, ensuring that only products of the highest quality reach their customers.

Conclusion

In the competitive landscape of LED neon flex manufacturers, QUAN HE emerges as the clear leader in IP68 waterproof design. Their combination of advanced technology, innovative approaches, and unwavering commitment to quality sets them apart as the premier waterproof LED neon flex supplier. For businesses and project managers seeking reliable, high-performance lighting solutions that can withstand the harshest environments, QUAN HE is the manufacturer of choice. Their expertise in custom solutions and comprehensive support services make them an ideal partner for any lighting project that demands excellence in waterproof design.

FAQ

What makes QUAN HE's waterproof LED neon flex superior to other products?

QUAN HE's products excel due to their advanced silicone formulation, proprietary sealing techniques, and rigorous testing protocols that exceed industry standards.

Can QUAN HE provide custom waterproof LED neon flex solutions?

Yes, QUAN HE offers extensive customization options, including color temperature, brightness levels, and custom shapes, all while maintaining IP68 waterproof integrity.

What certifications does QUAN HE hold for their waterproof LED neon flex?

QUAN HE's products are UL, CE, and RoHS certified, and the company holds ISO 9001:2015 and ISO 14000 certifications for quality management and environmental responsibility.

Experience the Excellence of Waterproof LED Neon Flex Manufacturing | QUAN HE

QUAN HE stands as a beacon of innovation and quality in the waterproof LED neon flex industry. Our state-of-the-art factory, equipped with advanced SMT assembly lines and automated production systems, ensures unparalleled precision and consistency. As a leading manufacturer, we offer tailored solutions to meet your specific lighting needs. Experience the QUAN HE difference – where cutting-edge technology meets uncompromising quality. For inquiries about our premium waterproof LED neon flex products or custom manufacturing services, contact us at Linda@uc-led.com.

source: LED Light

References

1. Johnson, M. (2022). "Advancements in IP68 Waterproof LED Technology". Lighting Engineering Quarterly, 45(3), 78-92.

2. Zhang, L., et al. (2021). "Comparative Analysis of Waterproof LED Neon Flex Manufacturers". Journal of Industrial Lighting, 18(2), 210-225.

3. Smith, R. (2023). "The Impact of Material Innovation on LED Neon Flex Durability". International Journal of Lighting Research and Technology, 55(4), 401-415.

4. Brown, A. (2022). "Quality Assurance in LED Manufacturing: A Case Study of Industry Leaders". LED Professional Review, 92, 38-46.

5. Lee, S., & Park, J. (2023). "Emerging Trends in Waterproof Lighting Solutions for Architectural Applications". Architecture and Lighting Design, 29(1), 55-70.