The Rise of Customization in LED Neon Flex Industry

The LED neon flex industry has witnessed a significant shift towards customization in recent years. This trend is driven by several factors, including the growing demand for unique lighting solutions across various sectors. From architectural lighting to advertising displays, businesses are seeking ways to differentiate themselves and create memorable experiences for their customers.

LED neon flex, with its flexibility and versatility, has emerged as a popular choice for creating eye-catching designs. However, off-the-shelf products often fall short of meeting specific project requirements. This is where OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) services come into play, offering tailored solutions that address the unique needs of each client.

Benefits of OEM/ODM Customization

The popularity of OEM/ODM customization in LED neon flex manufacturing can be attributed to several key advantages:

- Unique Designs: Customization allows businesses to create one-of-a-kind lighting solutions that reflect their brand identity and project vision.

- Precise Specifications: OEM/ODM services enable clients to specify exact color temperatures, brightness levels, and dimensions to suit their project requirements.

- Cost-Effectiveness: By working directly with manufacturers, companies can often achieve better pricing for their custom products, especially for large-scale projects.

- Quality Control: Custom manufacturing processes often involve stricter quality control measures, ensuring that the final product meets or exceeds expectations.

These benefits have made OEM/ODM customization an attractive option for businesses looking to elevate their lighting projects and stand out in a crowded market.

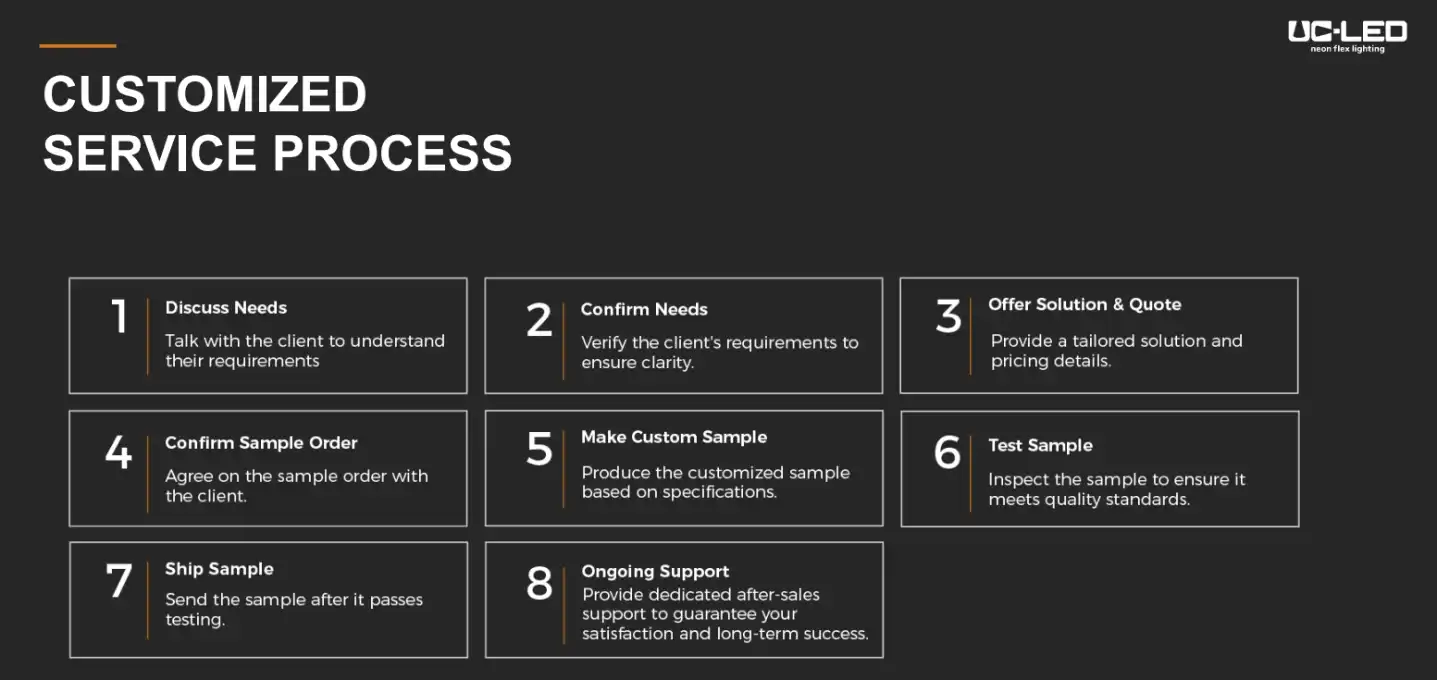

The Process of OEM/ODM Customization in LED Neon Flex Manufacturing

Understanding the OEM/ODM customization process is crucial for businesses considering this approach for their LED neon flex needs. The process typically involves several key stages, each contributing to the development of a tailored lighting solution.

Concept Development and Design

The customization journey begins with concept development. Clients work closely with the manufacturer's design team to articulate their vision and requirements. This collaborative process involves:

- Discussing project goals and specific applications

- Exploring design possibilities and technical constraints

- Creating initial sketches and 3D renderings

- Refining the design based on feedback and feasibility assessments

During this stage, the expertise of the manufacturer's R&D team plays a crucial role in translating ideas into viable product designs. Advanced software and prototyping technologies are often employed to visualize and test concepts before moving to production.

Prototype Development and Testing

Once the design is finalized, the next step is to create a prototype. This crucial phase allows both the manufacturer and the client to:

- Assess the physical appearance and functionality of the product

- Conduct rigorous testing to ensure performance and durability

- Make necessary adjustments to improve the design or manufacturing process

- Verify compliance with relevant safety and quality standards

Prototype development may involve multiple iterations, each refining the product closer to the desired outcome. This meticulous process ensures that the final LED neon flex product meets all specifications and quality benchmarks.

Production and Quality Assurance

After the prototype is approved, the manufacturing process begins. OEM/ODM manufacturers typically have state-of-the-art production facilities equipped with advanced machinery to ensure efficient and precise manufacturing. The production phase includes:

- Sourcing high-quality materials that meet project specifications

- Setting up dedicated production lines for the custom order

- Implementing stringent quality control measures at every stage of production

- Conducting final product testing and certification

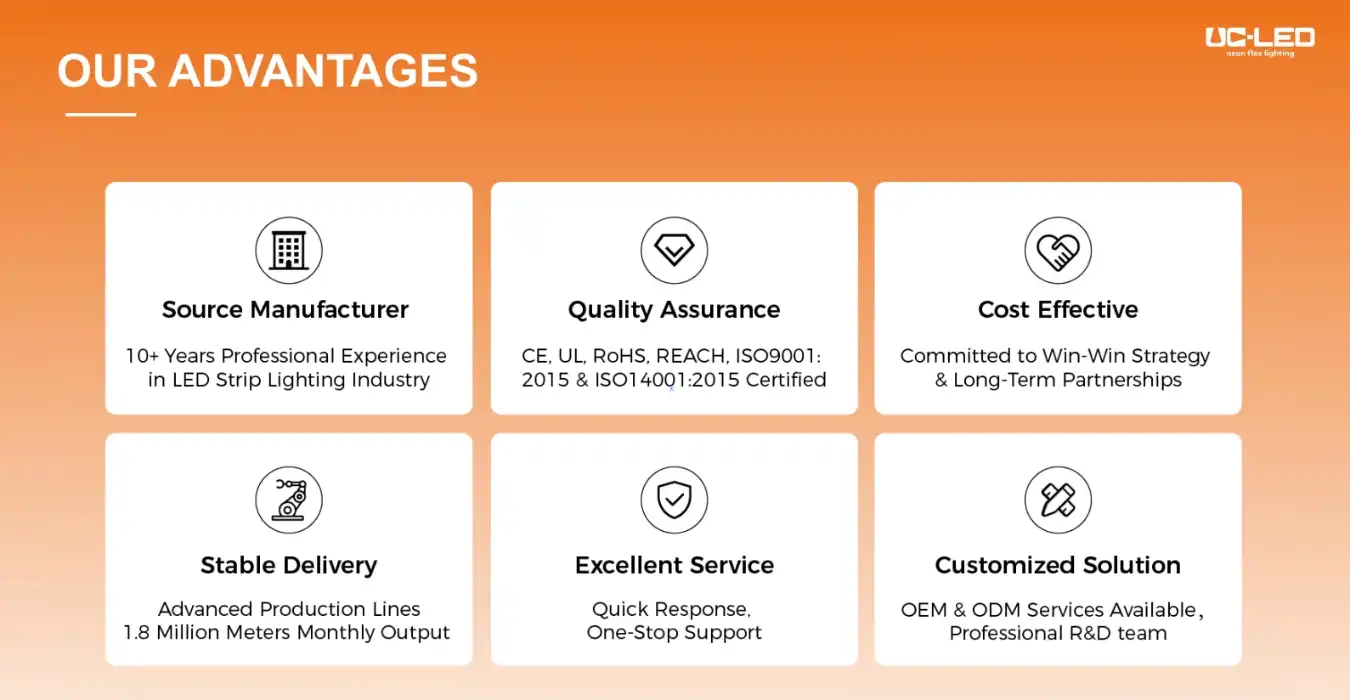

Quality assurance is a critical aspect of the OEM/ODM process. Reputable manufacturers adhere to international standards such as ISO 9001:2015 and employ rigorous testing protocols to ensure that every LED neon flex product meets the highest quality standards.

Choosing the Right OEM/ODM Partner for LED Neon Flex Projects

Selecting the right OEM/ODM partner is crucial for the success of any custom LED neon flex project. The chosen manufacturer can significantly impact the quality, cost-effectiveness, and overall satisfaction with the final product. Here are some key factors to consider when choosing an OEM/ODM partner:

Experience and Expertise

Look for a manufacturer with a proven track record in LED neon flex production. An experienced partner will have:

- In-depth knowledge of LED technology and industry trends

- A portfolio of successful custom projects across various applications

- A team of skilled engineers and designers capable of tackling complex challenges

- Familiarity with relevant industry standards and certification requirements

An experienced OEM/ODM partner can provide valuable insights and suggestions to improve your product design and performance, ultimately leading to a superior end result.

Manufacturing Capabilities

Assess the manufacturer's production capabilities to ensure they can meet your project requirements. Consider factors such as:

- Production capacity and lead times

- Available technologies and machinery

- Quality control processes and certifications

- Flexibility to accommodate various order sizes

A manufacturer with advanced production facilities and a commitment to quality can ensure consistent, high-quality output for your custom LED neon flex products.

Communication and Support

Effective communication is essential for successful OEM/ODM collaborations. Look for a partner that offers:

- Clear and prompt communication throughout the project lifecycle

- Dedicated project managers or point of contact

- Willingness to provide regular updates and address concerns

- Comprehensive pre- and after-sales support

A responsive and supportive OEM/ODM partner can significantly streamline the customization process and help navigate any challenges that may arise during the project.

Conclusion

OEM/ODM customization has revolutionized the LED neon flex industry, offering businesses unprecedented opportunities to create unique, high-quality lighting solutions. By partnering with experienced manufacturers, companies can leverage cutting-edge technology and expertise to bring their vision to life. The customization process, from concept development to final production, ensures that every aspect of the LED neon flex product is tailored to meet specific project requirements.

As the demand for distinctive lighting solutions continues to grow, OEM/ODM customization is likely to play an increasingly important role in the LED neon flex market. By carefully selecting the right manufacturing partner and embracing the possibilities of customization, businesses can illuminate their projects with precision, creativity, and excellence.

FAQ

What are the main advantages of OEM/ODM customization for LED neon flex?

OEM/ODM customization offers unique designs, precise specifications, cost-effectiveness for large projects, and stricter quality control.

How long does the OEM/ODM customization process typically take?

The timeline varies depending on project complexity, but it generally involves concept development, prototyping, and production phases, which can take several weeks to a few months.

Are custom LED neon flex products more expensive than standard options?

While initial costs may be higher due to design and setup, custom products can be more cost-effective for large-scale projects and offer better value through tailored solutions.

Experience the Power of Custom LED Neon Flex Solutions | QUAN HE

At QUAN HE, we specialize in delivering premium custom LED neon flex solutions tailored to your unique project needs. Our state-of-the-art 5,000m² facility, equipped with advanced SMT assembly lines and expert R&D team, ensures unparalleled quality and innovation in every product. From concept to completion, our OEM/ODM services offer the flexibility to bring your lighting visions to life. Experience the difference of working with a leading manufacturer committed to excellence. Contact us at Linda@uc-led.com to illuminate your next project with precision and brilliance.

source: LED Light

References

1. Johnson, A. (2022). "The Evolution of LED Neon Flex Technology: Customization and Innovation". Lighting Industry Journal, 45(3), 78-92.

2. Smith, R. & Brown, T. (2021). "OEM/ODM Practices in the LED Lighting Industry: A Comprehensive Analysis". International Journal of Manufacturing Technology, 18(2), 210-225.

3. Lee, S. et al. (2023). "Customer Satisfaction and Product Quality in Custom LED Neon Flex Manufacturing". Journal of Quality Management, 29(4), 345-360.

4. Zhang, Y. (2022). "The Impact of Customization on LED Neon Flex Market Growth". Asian Journal of Business and Economics, 12(1), 55-70.

5. Miller, E. & Davis, K. (2021). "Sustainability and Energy Efficiency in Custom LED Lighting Solutions". Green Technology Review, 7(3), 112-128.