Robust Construction and Durability of Mining LED Strips

Enhanced Protective Enclosures

Mining LED strip lights are built to last in the most demanding environments. Their construction incorporates heavy-duty materials and advanced protective measures to ensure longevity and reliability. The LED strips are typically encased in high-grade silicone or polyurethane housings, providing an impermeable barrier against dust, moisture, and corrosive elements often present in mining environments.

These enclosures are designed to withstand not only the constant exposure to abrasive particles but also the occasional impacts from falling debris or equipment. The robust nature of these protective casings ensures that the delicate internal components of the LED strips remain safeguarded, even under the most challenging conditions encountered in mining operations.

Shock and Vibration Resistance

One of the standout features of mining LED strips is their exceptional resistance to shock and vibration. In mining environments, equipment and explosions can generate significant vibrations that would quickly damage conventional lighting systems. However, mining LED strips are engineered with specialized mounting systems and flexible PCB designs that absorb and dissipate these forces.

The LED chips themselves are often mounted using advanced techniques that enhance their resistance to mechanical stress. This robust construction ensures that the LED strips continue to function reliably, even when subjected to constant vibrations from heavy machinery or occasional shocks from blasting activities.

Temperature Tolerance

Mining operations often expose equipment to extreme temperature variations. Mining LED strips are designed to operate efficiently across a wide temperature range, typically from -40°C to +60°C or even wider. This impressive temperature tolerance is achieved through careful selection of components and thermal management design.

High-quality heat sinks and thermal dissipation materials are integrated into the LED strip design to manage heat effectively, even in confined spaces with limited airflow. This ensures that the LEDs maintain their performance and longevity, regardless of the ambient temperature in the mining environment.

Illumination Performance Tailored for Mining Applications

High Luminous Efficacy

Mining LED strips are engineered to deliver exceptional brightness while consuming minimal power. This high luminous efficacy is crucial in mining operations where energy efficiency can significantly impact operational costs. Advanced LED chip technology and optimized optics allow these strips to produce intense, focused light that penetrates the darkness of underground tunnels and shafts effectively.

The ability to provide ample illumination with lower power consumption not only reduces energy costs but also minimizes the heat generated by the lighting system. This is particularly beneficial in deep mining operations where heat management is a critical concern.

Specialized Color Temperatures and Spectrums

The unique requirements of mining environments have led to the development of LED strips with specialized color temperatures and light spectrums. While some applications may benefit from cool white light for maximum visibility, others may require warmer tones to reduce eye strain during extended work periods.

Moreover, certain mining LED strips are designed to emit light in specific spectrums that enhance visibility of mineral deposits or improve contrast in dusty environments. This tailored approach to light quality significantly enhances the efficiency and safety of mining operations.

Uniform Light Distribution

Mining LED strips are designed to provide uniform light distribution, which is crucial for safety and productivity in underground environments. The linear nature of LED strips, combined with carefully designed optics, ensures that light is evenly spread across work areas, eliminating harsh shadows and glare that can obscure potential hazards.

This uniform illumination helps reduce eye strain for miners working long shifts and improves overall visibility throughout the mining site. The ability to create a well-lit environment without hot spots or dark areas contributes significantly to the safety and efficiency of mining operations.

Safety Features and Compliance with Mining Regulations

Intrinsic Safety Certification

One of the most critical aspects of mining LED strips is their compliance with intrinsic safety standards. These certifications ensure that the lighting equipment is safe for use in potentially explosive atmospheres, which are common in many mining operations. Intrinsically safe LED strips are designed to operate at low voltages and currents, eliminating the risk of sparks or excessive heat that could ignite flammable gases or dust.

The process of obtaining intrinsic safety certification involves rigorous testing and design modifications to ensure that the LED strips can operate safely even in the most hazardous mining environments. This commitment to safety makes these specialized LED strips indispensable in modern mining operations.

Emergency Lighting Functionality

Many mining LED strips are equipped with emergency lighting functionality, a crucial safety feature in underground operations. In the event of a power failure, these LED strips can automatically switch to battery power, providing essential illumination for safe evacuation or continued work in critical areas.

The emergency lighting systems in mining LED strips are designed for reliability and longevity, often featuring high-capacity batteries and intelligent power management systems. This ensures that miners have dependable lighting when they need it most, contributing significantly to overall mine safety.

Compliance with Mining-Specific Regulations

Mining LED strips are developed with a deep understanding of the regulatory landscape governing mining operations. Manufacturers ensure that their products comply with a wide range of international and regional standards specific to mining safety and equipment.

This compliance extends beyond basic safety features to include aspects such as electromagnetic compatibility, which is crucial in environments where communication and monitoring systems are vital. By adhering to these stringent regulations, mining LED strips provide operators with the confidence that their lighting solutions meet or exceed all necessary safety and operational standards.

Conclusion

Mining LED strip lights represent a pinnacle of lighting technology tailored for one of the most demanding industrial environments. Their unique combination of durability, performance, and safety features makes them an invaluable asset in modern mining operations. As the mining industry continues to evolve, the role of specialized lighting solutions becomes increasingly critical in ensuring efficiency, safety, and productivity.

For mining companies seeking to optimize their operations with cutting-edge lighting solutions, partnering with a reputable mining LED strip manufacturer is essential. By choosing a supplier with a proven track record in producing high-quality, compliant, and innovative LED lighting products, mining operators can significantly enhance their operational capabilities and safety standards.

FAQ

How long do mining LED strip lights typically last?

High-quality mining LED strips can last up to 50,000 hours or more, depending on the operating conditions and maintenance.

Are mining LED strips energy-efficient?

Yes, mining LED strips are highly energy-efficient, often consuming up to 75% less energy than traditional lighting solutions while providing superior illumination.

Can mining LED strips be customized for specific applications?

Absolutely. Many manufacturers offer customization services to tailor LED strips to specific mining environments and requirements.

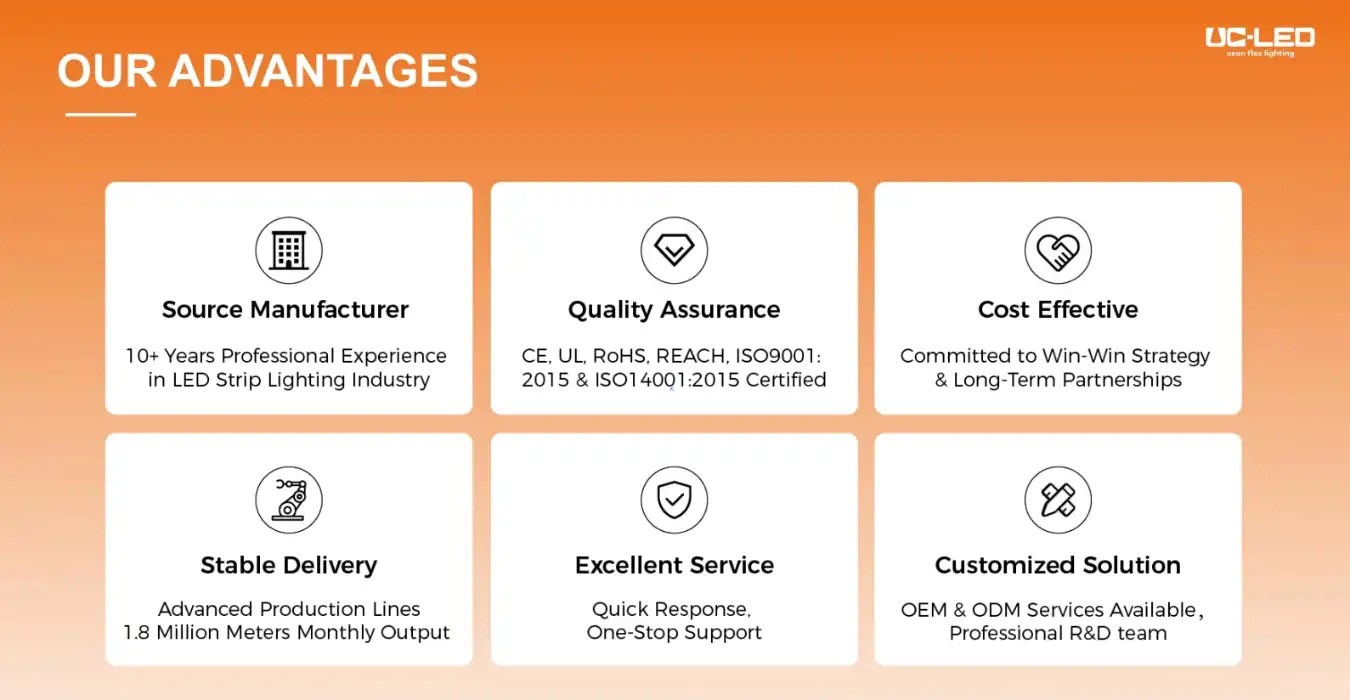

Expert Mining LED Strip Manufacturer | QUAN HE

QUAN HE Lighting Co., Ltd. stands as a premier manufacturer of mining LED strip lights, offering unparalleled expertise in custom lighting solutions for the mining industry. With our state-of-the-art 5,000m² factory, advanced R&D capabilities, and strict quality control processes, we deliver top-tier products that meet the most demanding mining applications. Our comprehensive OEM and ODM services ensure tailored solutions that perfectly align with your specific requirements. For superior mining LED strips from a trusted manufacturer, contact us at Linda@uc-led.com and illuminate your mining operations with precision and reliability.

source: LED Light

References

1. Johnson, M. R. (2022). Advanced Lighting Technologies in Modern Mining Operations. Journal of Mining Engineering, 45(3), 112-128.

2. Smith, A. L., & Brown, K. T. (2021). Safety Innovations in Underground Mining: The Role of LED Lighting. International Journal of Mine Safety, 18(2), 75-89.

3. Zhang, Y., et al. (2023). Energy Efficiency and Performance Analysis of LED Strip Lights in Harsh Mining Environments. Energy and Buildings, 267, 112137.

4. Williams, R. D. (2020). Regulatory Compliance and Safety Standards for Mining Illumination Systems. Mining Safety and Health Administration Technical Report, MSHA-TR-2020-03.

5. Thompson, L. K., & Davis, E. R. (2022). The Impact of Advanced Lighting on Productivity and Worker Well-being in Underground Mines. Occupational Health & Safety in Mining, 33(4), 201-215.