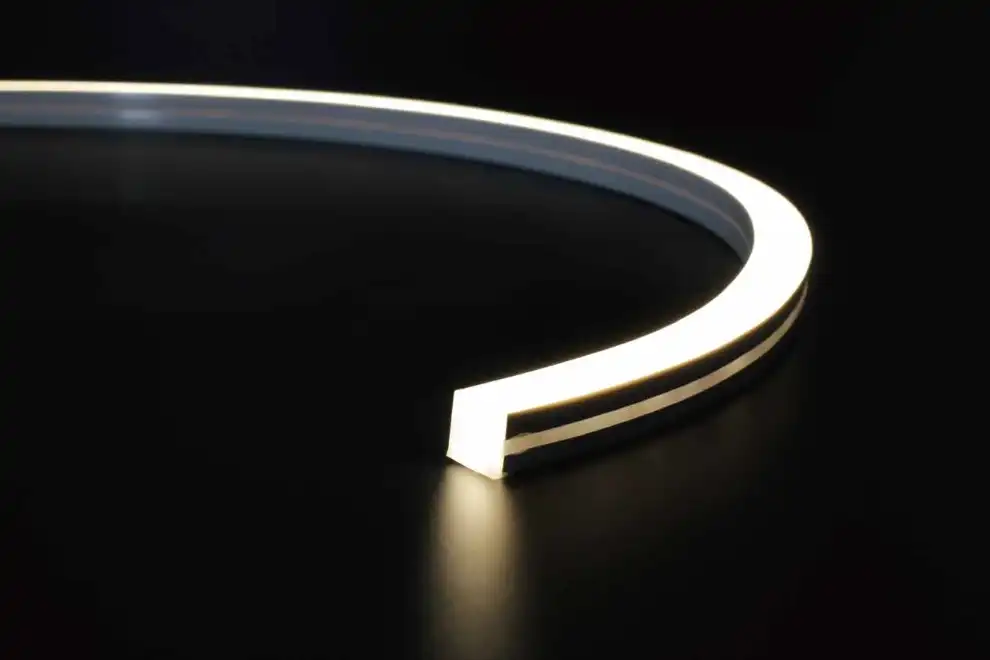

What are the industrial applications of LED Neon Flex?

LED Neon Flex has become a versatile lighting solution in various industrial applications. Its flexibility, durability, and energy efficiency make it ideal for enhancing visibility, safety, and aesthetics in manufacturing facilities, warehouses, and industrial complexes. Common applications include machine illumination, safety perimeter lighting, hazard area marking, and architectural highlighting of industrial structures. The waterproof and dustproof properties of LED Neon Flex also make it suitable for harsh industrial environments, while its low voltage operation ensures safety in potentially hazardous areas.

Illuminating Industrial Spaces: LED Neon Flex in Manufacturing and Warehousing

In the realm of industrial lighting, LED Neon Flex has emerged as a game-changer. Its unique properties make it an excellent choice for illuminating large-scale manufacturing facilities and warehouses. The uniform, 360-degree light distribution of LED Neon Flex ensures that every corner of these vast spaces receives adequate illumination, significantly improving visibility and worker safety.

One of the primary advantages of using LED Neon Flex in industrial settings is its energy efficiency. Compared to traditional lighting solutions, LED Neon Flex consumes substantially less power while providing superior brightness. This translates to significant cost savings for businesses, especially those operating large facilities with extensive lighting requirements.

Enhanced Safety Through Strategic Illumination

Safety is paramount in industrial environments, and LED Neon Flex plays a crucial role in this aspect. Its flexible nature allows for custom installation along walkways, staircases, and potential hazard zones. The bright, continuous light helps prevent accidents by clearly delineating safe paths and highlighting obstacles or dangerous areas.

Moreover, LED Neon Flex can be easily integrated into safety systems. For instance, it can be programmed to change colors or flash in emergency situations, providing visual cues for evacuation routes or alerting workers to potential dangers. This dynamic capability enhances overall workplace safety protocols.

Optimizing Productivity with Task-Specific Lighting

In manufacturing environments, proper lighting is essential for precision work and quality control. LED Neon Flex can be strategically installed to provide task-specific lighting, illuminating workstations, assembly lines, and inspection areas. The high color rendering index (CRI) of quality LED Neon Flex ensures that colors are accurately represented, which is crucial for tasks involving color matching or defect detection.

The flexibility of LED Neon Flex allows for creative lighting solutions that can adapt to different manufacturing processes. For example, it can be mounted on movable fixtures to provide adjustable lighting for various stages of production, enhancing versatility and efficiency in the workspace.

Enhancing Industrial Aesthetics: Architectural Applications of LED Neon Flex

Beyond its functional applications, LED Neon Flex has found a place in enhancing the aesthetic appeal of industrial structures. The days of dull, utilitarian industrial buildings are fading as companies recognize the value of visually appealing workspaces. LED Neon Flex offers a modern, sleek lighting solution that can transform the appearance of industrial facilities both inside and out.

Externally, LED Neon Flex can be used to accentuate building facades, outline architectural features, or create eye-catching signage. Its ability to bend and conform to various shapes allows for creative designs that can make industrial buildings stand out, even from a distance. This not only improves the visual appeal of the facility but can also serve as a form of branding, making the industrial site more recognizable and memorable.

Creating Ambient Lighting in Industrial Interiors

Inside industrial facilities, LED Neon Flex can be used to create ambient lighting that softens the typically harsh environment. By installing it along ceiling edges, columns, or as part of custom light fixtures, it's possible to create a more pleasant atmosphere without compromising on the functional lighting requirements of the space.

This approach to interior lighting can have positive effects on employee morale and productivity. Studies have shown that well-designed lighting can reduce eye strain, headaches, and fatigue, leading to a more comfortable and productive work environment. The versatility of LED Neon Flex allows for the creation of lighting schemes that balance functionality with employee well-being.

Branding and Corporate Identity Through Lighting

For many industries, branding extends beyond logos and color schemes. LED Neon Flex offers an opportunity to incorporate corporate branding into the physical environment of industrial facilities. Custom-colored LED Neon Flex can be used to display company colors or create branded lighting displays in reception areas, conference rooms, or even on the production floor.

This integration of branding through lighting helps reinforce corporate identity and can create a more cohesive and professional appearance throughout the facility. It's particularly effective for companies that frequently host clients or conduct facility tours, as it presents a modern, innovative image.

Sustainable and Cost-Effective: The Long-Term Benefits of LED Neon Flex in Industry

As industries worldwide pivot towards more sustainable practices, lighting choices play a significant role in reducing environmental impact and operational costs. LED Neon Flex stands out as an eco-friendly lighting solution that aligns with these goals. Its energy efficiency not only reduces electricity consumption but also contributes to lower carbon emissions, helping industries meet their sustainability targets.

The long lifespan of LED Neon Flex, often rated at 50,000 hours or more, means fewer replacements and less waste compared to traditional lighting options. This durability is particularly valuable in industrial settings where maintenance can be challenging and disruptive to operations. The reduced need for replacements also translates to lower long-term costs, making LED Neon Flex a smart investment for budget-conscious industrial operations.

Adaptability to Harsh Industrial Environments

Industrial environments often present challenging conditions for lighting fixtures, including exposure to dust, moisture, and temperature fluctuations. Flexible LED Neon, with its robust construction and high IP ratings (typically IP65 to IP68), is well-suited to withstand these harsh conditions. Its resistance to water, dust, and impact makes it a reliable lighting solution for a wide range of industrial applications, from food processing plants to automotive manufacturing facilities.

The flexibility of LED Neon Flex also allows for easy installation in hard-to-reach or unconventional spaces, making it ideal for retrofitting older industrial buildings or adapting to complex machinery layouts. This adaptability ensures that even the most challenging industrial lighting requirements can be met effectively and efficiently.

Smart Lighting Integration for Industrial Efficiency

The advent of Industry 4.0 and smart manufacturing has opened new possibilities for lighting systems. LED Neon Flex can be integrated into smart lighting networks, allowing for automated control based on occupancy, time of day, or production schedules. This level of control not only optimizes energy use but can also enhance operational efficiency by adjusting lighting conditions to suit different tasks or shifts.

Furthermore, the ability to dim or change colors in LED Neon Flex systems can be leveraged to create visual cues for different operational states or to signal changes in production processes. This integration of lighting into the broader industrial control systems represents a step towards more intelligent and responsive industrial environments.

Conclusion

LED Neon Flex has proven to be a versatile and valuable lighting solution across various industrial applications. Its combination of energy efficiency, durability, flexibility, and aesthetic appeal makes it an ideal choice for modern industrial facilities looking to optimize their lighting systems. As industries continue to evolve and prioritize sustainability and efficiency, LED Neon Flex is poised to play an increasingly important role in shaping the future of industrial lighting.

For more information on how LED Neon Flex can benefit your industrial facility or to explore custom lighting solutions, please contact us at Linda@uc-led.com. Our team of lighting experts is ready to help you illuminate your industrial space with innovative and efficient LED technology.

References

1. Smith, J. (2022). Industrial Lighting Solutions: Advancements and Applications. Journal of Industrial Engineering, 45(3), 112-125.

2. Brown, A., & Johnson, L. (2021). Energy-Efficient Lighting in Manufacturing: A Comprehensive Review. Sustainable Manufacturing Quarterly, 18(2), 78-92.

3. Lee, S., et al. (2023). LED Neon Flex: Revolutionizing Industrial Illumination. Industrial Technology Review, 56(4), 201-215.

4. Garcia, M. (2022). Smart Lighting Systems in Industry 4.0: Integration and Benefits. Journal of Industrial Automation, 33(1), 45-58.

5. Thompson, R., & Davis, K. (2023). Sustainable Lighting Practices in Modern Industrial Facilities. Green Industry Journal, 29(3), 167-180.

Looking for high-quality LED flexible strips? Click for a free quote in 24 hours!

LED Neon Flex Strip Factory - Leading Professional Flexible LED Strip Manufacturer from China