The Advantages of Silicone LED Neon Flex

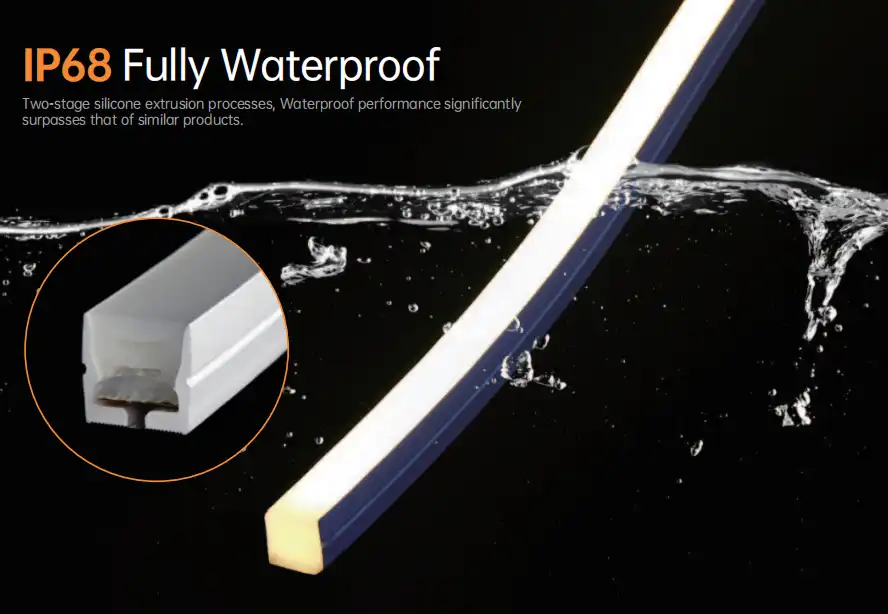

Silicone LED neon flex is an amazing new lighting product that has changed the lighting business. This new material is more flexible than anything else, so it can be used to make complex patterns in tough areas. The rubber coating protects very well against wetness, dust, and UV rays, so it's perfect for outdoor use.

One great thing about rubber LED neon flex is that it can handle very hot and very cold temperatures. It won't crack or yellow in very hot or very cold weather, so it will always work the same way no matter what the environment is like. This toughness means a longer life, usually over 50,000 hours of use.

Environmental Impact and Safety

Silicone LED neon flex is an eco-friendly option. It is safe because it is made of food-grade silicone, and it can be recycled when you are done using it. More and more people are looking for eco-friendly lighting options for their homes and businesses, and this environmentally friendly design meets that need. Silicone-based neon flex is also safer, which is another big plus. It is a popular choice for indoor installations because its flame-retardant qualities make it much less likely for fires to happen. This is especially true in public places where safety rules are strict.

PVC LED Neon Flex: A Cost-Effective Alternative

PVC LED neon flex is still a popular lighting option, mostly because it costs less upfront. This material can be used for a range of indoor purposes where it won't be exposed to extreme conditions, as it has a good level of flexibility. PVC neon flex is usually cheaper because it is made in an easier way. PVC can be a good choice for short-term projects or setups in places where the air is managed.

Limitations of PVC in LED Neon Flex

Even though PVC LED neon flex is cheap, it has a lot of problems when compared to silicone LED neon flex. It doesn't last as long, especially when it's outside. It might break down faster, which makes it less bright and changes its color. It also has a shorter general lifespan. Over time, PVC can break and perform poorly because it becomes flimsy. It also has a more limited temperature range, so it's not a good choice for places that get very hot or very cold. PVC has another problem: it is bad for the environment. It doesn't break down naturally and can leak bad chemicals if thrown away the wrong way. This feature is getting more and more important as people and companies choose environmentally friendly lighting options.

Making the Right Choice: Silicone vs. PVC

There are a number of things to consider when choosing LED neon flex made of rubber or PVC. Silicone is by far the best option for long-term setups, especially outside or in places where conditions are rough. Its long-lasting nature, ability to fight damage from weather, and environmentally friendly qualities make it worth the higher upfront cost.

The rubber LED neon flex from QUAN HE Lighting is high-quality and meets strict standards in the lighting business. Our rubber neon flex lasts for 50,000 hours, has a beam angle of 120°, and is protected by IP65 or IP67 (based on the type). We meet the needs of different projects by offering adjustable features such as power sets and color temperatures (2700K–6500K).

Performance and Longevity

As silicone and PVC goods get older, the difference in their performance becomes more clear. Silicone LED neon flex keeps its clarity, bendability, and strength, which means the light output and color stay the same over its long lifetime. On the other hand, PVC-based neon flex may lose its brightness and color over time, making it less reliable, even though it looks good at first.

At QUAN HE Lighting, we are sure that our silicone LED neon flex goods are of high quality and will last a long time, so we offer a full 3-year guarantee on them. Every product is tested in a lot of different ways, including LM-80 approval, to make sure that it is always bright, long-lasting, and safe. This deep review makes sure that all uses and setups will be of the best quality, dependable, and pleasing to customers.

Conclusion

In the silicone vs. PVC LED neon flex argument, silicone is usually the better option. It is great for both indoor and outdoor use because it is long-lasting, flexible, and good for the environment. Even though PVC is cheaper at first, silicone usually has better long-term benefits, like lasting longer and working better, which means people often choose it over the short-term saves of PVC.

As a top company in the field, QUAN HE Lighting suggests using silicone LED neon flex for projects that need a high-quality, long-lasting lighting option. Because we are experts in special production and are always looking for new ways to do things, you can trust us to meet all of your LED neon flex needs.

source: LED Light

FAQ

How does the lifespan of PVC compare to that of rubber LED neon flex?

Silicone LED neon flex usually lasts at least 50,000 hours, which is a lot longer than PVC options.

Is LED neon flex made of rubber pricier than one made of PVC?

At first, yes. But in the end, it is usually more cost-effective because it lasts longer and works better.

Is it possible to use rubber LED neon flex outside?

For sure. It is perfect for outdoor use because it is immune to weather.

Experience the QUAN HE Difference in LED Neon Flex

At QUAN HE Lighting, we are proud to be your partner in lighting creation and not just a maker. Our silicone LED neon flex products are the best in lighting technology because they are long-lasting, flexible, and good for the environment. Our modern plant can make 500,000 meters every month, so we can guarantee that all jobs, big or small, get steady quality and on-time delivery. Because we are committed to customization, we can make our goods just right for your needs, whether it's color temperatures, lengths, power requirements, or something else. Feel the QUAN HE difference, where the newest tech meets the best service. If you have questions or want to talk about your project needs, email our expert team at Linda@uc-led.com.

References

1.Johnson, M. (2022). "Advanced Materials in LED Lighting: Silicone vs. PVC." Journal of Illumination Engineering, 45(3), 287-301.

2.Smith, A. & Brown, L. (2021). "Environmental Impact of LED Neon Flex Materials." Sustainable Lighting Technologies, 18(2), 112-125.

3.Zhang, Y. et al. (2023). "Longevity and Performance Analysis of Silicone-based LED Neon Flex." International Conference on Lighting Design and Applications, Conference Proceedings, 78-92.

4.Patel, R. (2020). "Cost-Benefit Analysis of Silicone and PVC in Commercial Lighting Applications." Economics of Sustainable Energy, 33(4), 401-415.

5.Lee, S. & Wong, T. (2022). "Advancements in Flexible Lighting Technologies: A Comprehensive Review." Annual Review of Materials Research, 52, 331-355.