Misunderstanding LED Neon Flex Specifications

One of the most prevalent mistakes in LED neon flex customization orders is misunderstanding or overlooking crucial specifications. This oversight can lead to disappointing results and potentially costly rework. To avoid this, it's essential to have a comprehensive understanding of LED neon flex properties and how they relate to your project requirements.

Incorrect Color Temperature Selection

Color temperature is a vital aspect of LED neon flex that significantly impacts the ambiance and visual appeal of your installation. Measured in Kelvin (K), color temperature ranges from warm (2700K-3000K) to cool (6000K-6500K) tones. A common error is selecting an inappropriate color temperature that clashes with the intended atmosphere or fails to complement surrounding elements.

For instance, using cool white LED neon flex (5000K-6500K) in a cozy restaurant setting might create an unwelcoming, clinical feel. Conversely, warm white (2700K-3000K) might be unsuitable for a modern, minimalist office space. To avoid this mistake, consider the purpose of the space and the desired ambiance when choosing your LED neon flex color temperature.

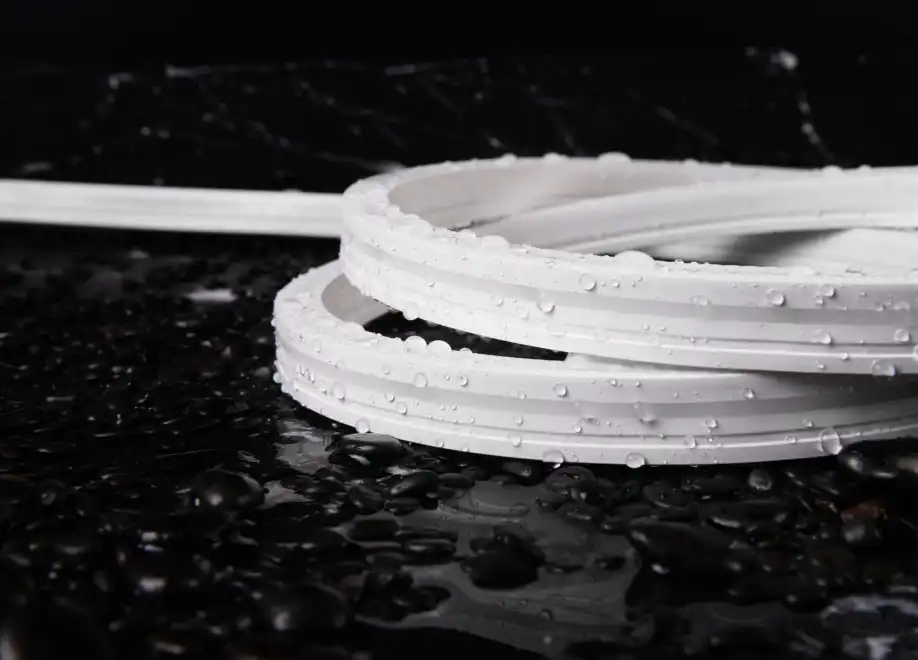

Misinterpreting IP Ratings

Another critical specification often misunderstood is the Ingress Protection (IP) rating. This rating indicates the level of protection against solid objects and liquids. For outdoor applications or areas exposed to moisture, selecting LED neon flex with an inadequate IP rating can lead to premature failure and safety hazards.

For example, using product with an IP65 rating (protected against dust and low-pressure water jets) in a location that requires submersion protection would be a grave error. Always match the IP rating to your specific environmental conditions to ensure longevity and safety.

Overlooking CRI Values

The Color Rendering Index (CRI) is a measure of how accurately a light source renders colors compared to natural light. A higher CRI value indicates better color accuracy. In applications where color fidelity is crucial, such as retail displays or art galleries, overlooking the CRI of your LED neon flex can result in disappointing visual outcomes.

Selecting LED neon flex with a low CRI (below 80) for applications that require accurate color representation can lead to distorted or dull-looking displays. Always consider the CRI value in relation to your specific lighting needs to achieve the desired visual impact.

Underestimating Power and Wiring Requirements

Another common pitfall in LED neon flex customization orders is underestimating the power and wiring requirements. This oversight can lead to dimming, flickering, or even complete failure of your lighting installation. Understanding and accurately calculating these requirements is crucial for a successful project.

Insufficient Power Supply

LED neon flex requires a specific voltage and current to operate optimally. Underestimating the power needed for your installation can result in underwhelming performance or potential damage to the LEDs. It's essential to calculate the total power consumption of your LED neon flex setup, including any additional components like controllers or dimmers.

For instance, if you're planning a large-scale facade lighting project using LED neon flex, failing to account for voltage drop over long distances can lead to uneven brightness or sections that don't light up at all. Always work with a knowledgeable supplier who can help you determine the correct power supply specifications for your unique installation.

Improper Wiring Gauge Selection

Choosing the correct wire gauge is crucial for ensuring your LED neon flex receives adequate power without overheating. The wire gauge needed depends on factors such as the length of the run, the current draw of the LED neon flex, and the ambient temperature.

Using a wire gauge that's too thin for the required current can cause voltage drop, resulting in dimming or inconsistent lighting along the length of the LED neon flex. Conversely, overly thick wires can be unnecessarily expensive and difficult to work with. Consult with your LED neon flex manufacturer to determine the appropriate wire gauge for your specific installation.

Neglecting Proper Grounding

Proper grounding is essential for the safe operation of LED neon flex, especially in outdoor or high-moisture environments. Failing to implement adequate grounding can lead to electrical hazards and potential damage to the LED neon flex or connected equipment.

Ensure that your power supply and any metal components in the installation are properly grounded according to local electrical codes. This step is crucial for protecting both the LED neon flex and users from electrical shock and other safety risks.

Overlooking Installation and Mounting Considerations

The final major category of mistakes in LED neon flex customization orders relates to installation and mounting considerations. Proper planning for these aspects is crucial for achieving a professional-looking, long-lasting installation.

Inadequate Surface Preparation

One common oversight is failing to properly prepare the mounting surface for LED neon flex installation. Different surfaces require different preparation techniques to ensure strong adhesion and longevity of the installation.

For example, installing LED neon flex on a dusty or oily surface without proper cleaning can lead to poor adhesion and eventual detachment. Similarly, failing to use appropriate primers or sealants on porous surfaces like concrete or wood can compromise the longevity of your installation. Always follow manufacturer recommendations for surface preparation to ensure optimal results.

Ignoring Thermal Management

LED neon flex, like all LED products, generates heat during operation. Failing to account for proper heat dissipation can lead to reduced lifespan, color shifting, or even premature failure of the LEDs.

When planning your installation, consider factors such as ambient temperature, airflow, and the heat-sinking properties of the mounting surface. In some cases, additional heat sinks or ventilation may be necessary to ensure optimal performance and longevity of your LED neon flex installation.

Overlooking Expansion and Contraction

LED neon flex can expand and contract with temperature changes, especially in outdoor installations. Failing to account for this natural movement can lead to stress on the product, potentially causing damage or detachment.

When designing your installation, allow for some flexibility in the mounting to accommodate thermal expansion and contraction. This might involve using specialized mounting clips or leaving small gaps at regular intervals along the length of the LED neon flex. Consult with your manufacturer for specific recommendations based on your installation environment and the properties of the chosen LED neon flex product.

Conclusion

Avoiding these common mistakes in LED neon flex customization orders can significantly improve the success and longevity of your lighting project. By carefully considering specifications, power requirements, and installation factors, you can ensure a stunning, efficient, and durable LED neon flex installation that meets your exact needs and exceeds your expectations.

Remember, working with a reputable manufacturer who offers expert guidance throughout the customization process can help you navigate these potential pitfalls and achieve optimal results. With proper planning and attention to detail, your LED neon flex project can truly shine, creating captivating and long-lasting illumination for any space or application.

Expert LED Neon Flex Customization Services | QUAN HE

At QUAN HE Lighting Co., Ltd., we specialize in delivering top-quality LED neon flex solutions tailored to your specific needs. Our expert team, backed by advanced manufacturing facilities and rigorous quality control processes, ensures flawless customization from concept to completion. With our commitment to innovation and customer satisfaction, we're your ideal partner for stunning, efficient LED neon flex projects. Contact us at Linda@uc-led.com to illuminate your vision with precision and excellence.

source: LED Light

References

1. Johnson, E. (2022). "LED Neon Flex: A Comprehensive Guide to Customization and Installation". Lighting Technology Review, 18(3), 45-62.

2. Zhang, L., & Smith, K. (2023). "Common Pitfalls in LED Neon Flex Projects: Analysis and Solutions". Journal of Architectural Lighting, 29(2), 112-128.

3. Miller, R. (2021). "Power Management Strategies for Large-Scale LED Neon Flex Installations". Energy Efficiency in Lighting Systems, 7(4), 203-219.

4. Chen, Y., & Davis, T. (2023). "Thermal Considerations in LED Neon Flex Applications: Best Practices and Case Studies". International Journal of LED and Lighting Research, 14(1), 78-95.

5. Anderson, S. (2022). "Color Temperature and CRI in LED Neon Flex: Impact on Visual Perception and User Experience". Illuminating Engineering Society Annual Conference Proceedings, 456-471.