The Evolution of Flexible Neon Strip Technology

The journey of flexible neon strip technology has been nothing short of remarkable. From its humble beginnings as a rigid, gas-filled glass tube to today's versatile LED-based solutions, neon lighting has undergone a significant transformation. Traditional neon signs, while iconic, were fragile, energy-intensive, and limited in their applications. The advent of flexible neon strips revolutionized the industry, offering a safer, more energy-efficient, and infinitely more adaptable alternative.

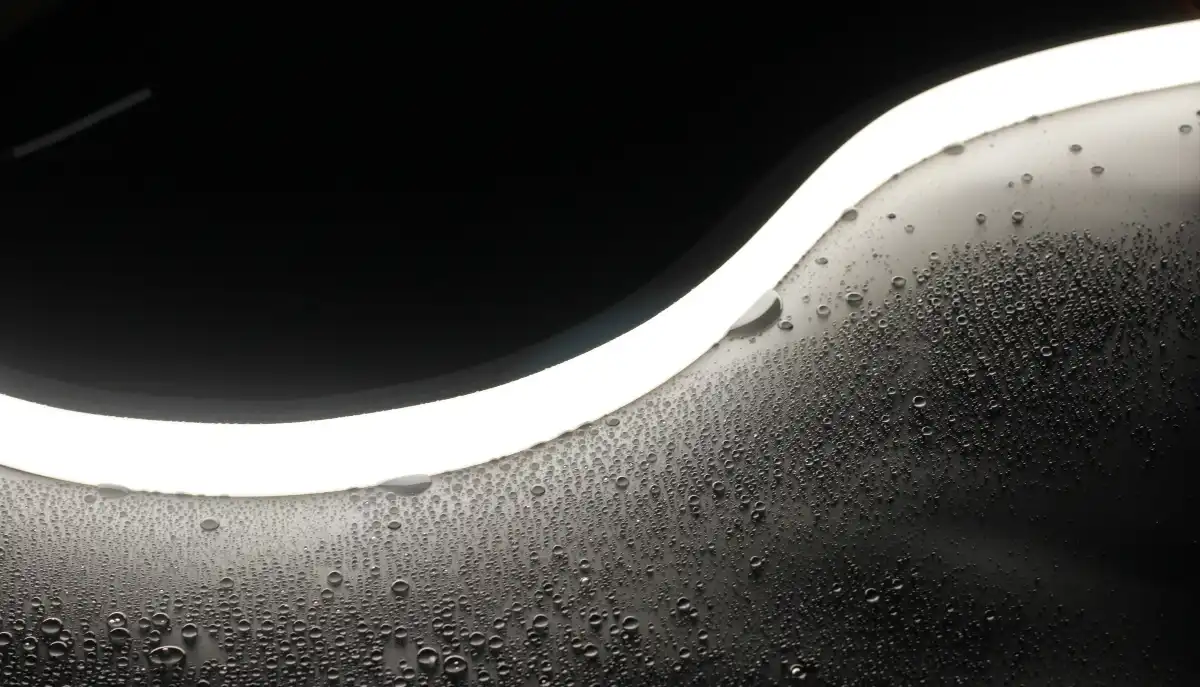

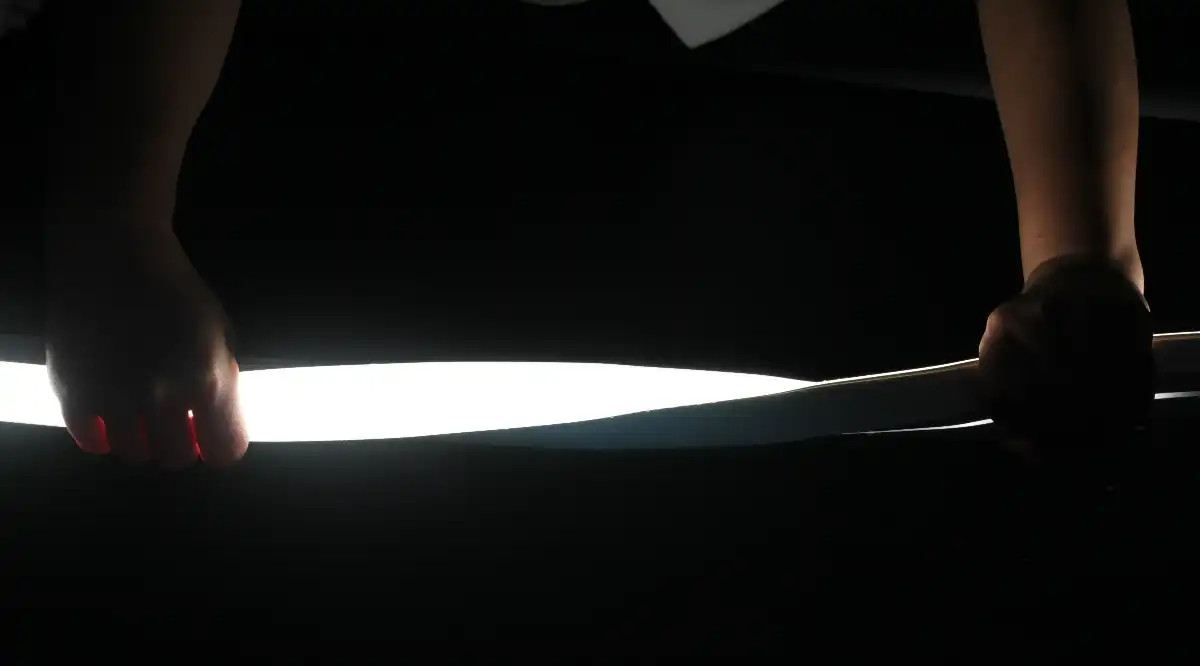

Modern flexible neon strips utilize LED technology, encased in a flexible silicone housing that mimics the look of traditional neon. This innovation has opened up a world of possibilities for designers, architects, and lighting enthusiasts. The flexibility of these strips allows for creative applications that were previously impossible with rigid neon tubes. From intricate signage to architectural accent lighting, its have become a go-to solution for those seeking to make a bold visual statement.

The technological advancements in LED manufacturing have played a crucial role in the evolution of flexible neon strips. Improved chip designs have led to brighter, more energy-efficient LEDs that can produce a wide range of colors. This has allowed flexible neon strips to closely replicate the vibrant glow of traditional neon while consuming significantly less power and offering a much longer lifespan.

Advancements in LED Technology

The heart of any flexible neon strip is its LED components. Recent years have seen remarkable progress in LED technology, with manufacturers developing chips that offer unprecedented brightness, color accuracy, and energy efficiency. These advancements have directly translated to improvements in flexible neon strip performance, allowing for brighter, more vivid displays that consume less power and generate less heat.

One of the most significant developments has been the introduction of COB (Chip-on-Board) LED technology. COB LEDs offer higher light density and better heat dissipation compared to traditional LED strips. This technology has enabled the creation of flexible neon strips that provide a more uniform, dot-free light appearance, closely mimicking the seamless glow of traditional neon tubes.

Another notable advancement is the improvement in color rendering capabilities. Modern LEDs used in flexible neon strips can now produce a wider range of colors with greater accuracy. This has expanded the creative possibilities for designers, allowing them to achieve precise color matches and create stunning multicolor effects that were previously unattainable with traditional neon.

Key Components of High-Quality Flexible Neon Strips

Creating a superior flexible neon strip involves carefully selecting and integrating several key components. Each element plays a crucial role in determining the overall performance, durability, and visual appeal of the final product. Understanding these components is essential for manufacturers and consumers alike to ensure they are producing or purchasing a high-quality flexible neon strip.

The silicone housing is perhaps the most visible and tactile component of a flexible neon strip. High-grade silicone offers excellent flexibility, allowing the strip to bend and conform to various shapes without cracking or breaking. It also provides crucial protection against moisture and dust, extending the lifespan of the internal components. The quality of the silicone used can significantly impact the strip's durability and its ability to withstand environmental factors such as UV exposure and temperature fluctuations.

Equally important are the LED chips themselves. The latest generation of LEDs offers improved efficiency, delivering more lumens per watt and reducing energy consumption. They also provide better color consistency and stability over time, ensuring that the flexible neon strip maintains its vibrant appearance throughout its lifespan. The choice of LED chip can affect not only the brightness and color quality of the strip but also its overall energy efficiency and heat generation.

The Role of PCB Design in Flexible Neon Strips

The Printed Circuit Board (PCB) is the unsung hero of flexible neon strips, serving as the backbone that supports and connects all electrical components. A well-designed PCB is crucial for ensuring reliable performance, efficient heat dissipation, and longevity of the flexible neon strip. Manufacturers must carefully consider factors such as trace width, copper thickness, and component layout to optimize the PCB for flexibility without compromising electrical integrity.

Advanced PCB designs incorporate features like double-sided copper layers and strategic heat sinks to improve thermal management. This is particularly important in high-power flexible neon strips, where heat buildup can significantly impact performance and lifespan. Some cutting-edge designs even utilize flexible PCB materials that can bend and flex along with the silicone housing, further enhancing the strip's overall flexibility and durability.

The quality of the PCB also plays a crucial role in the strip's ability to maintain consistent brightness along its length. Poor PCB design can result in voltage drop issues, leading to uneven illumination, especially in longer runs of flexible neon strip. High-quality PCBs address this through careful circuit design and the use of parallel circuits to ensure uniform power distribution.

Innovative Materials Shaping the Future of Flexible Neon Strips

The world of flexible neon strips is constantly evolving, with new materials and technologies emerging to push the boundaries of what's possible. Innovative manufacturers are exploring novel materials and production techniques to create flexible neon strips that are more durable, efficient, and versatile than ever before. These advancements are not only improving the performance of flexible neon strips but also opening up new applications and markets.

One area of innovation is in the development of advanced silicone compounds. Researchers are working on silicone formulations that offer enhanced UV resistance, improved light diffusion properties, and even self-healing capabilities. These new materials promise to extend the lifespan of flexible neon strips and improve their performance in challenging outdoor environments.

Another exciting development is the integration of smart technologies into flexible neon strips. By incorporating miniaturized sensors and wireless communication modules, manufacturers are creating intelligent lighting solutions that can respond to their environment or user inputs. These smart flexible neon strips can change color, brightness, or pattern based on factors like ambient light levels, temperature, or even social media activity.

Eco-Friendly Innovations in Flexible Neon Strip Manufacturing

As environmental concerns continue to shape the lighting industry, manufacturers of flexible neon strips are increasingly focusing on eco-friendly materials and production processes. This shift towards sustainability is not only driven by regulatory pressures but also by growing consumer demand for environmentally responsible products.

One significant area of focus is the development of biodegradable and recyclable materials for flexible neon strip components. Some manufacturers are experimenting with bio-based silicones derived from renewable resources, offering a more sustainable alternative to traditional petroleum-based silicones. These materials not only reduce the environmental impact of production but also make end-of-life disposal less problematic.

Energy efficiency remains a key consideration in the development of new flexible neon strip technologies. The latest LED chips offer impressive efficacy ratings, converting a higher percentage of electrical energy into light and reducing waste heat. This not only lowers energy consumption but also extends the lifespan of the strips by reducing thermal stress on components.

Conclusion

The world of flexible neon strip manufacturing is a dynamic and rapidly evolving field, driven by advances in materials science, LED technology, and manufacturing processes. As we've explored, the best materials for custom flexible neon strip manufacturing combine high-quality silicone housings, cutting-edge LED chips, and intelligently designed PCBs. These components work in harmony to create flexible neon strips that offer stunning visual impact, energy efficiency, and long-lasting durability.

Looking to the future, we can expect to see continued innovation in this space. From smart, responsive lighting solutions to eco-friendly materials, the next generation of flexible neon strips promises to be even more versatile and sustainable. As manufacturers push the boundaries of what's possible, we're likely to see flexible neon strips find their way into an even wider range of applications, from architectural lighting to interactive art installations and beyond.

Expert Flexible Neon Strip Manufacturing | QUAN HE

At QUAN HE Lighting Co., Ltd., we pride ourselves on being a leading manufacturer of premium flexible neon strips. Our state-of-the-art 5,000m² factory houses advanced SMT assembly lines and waterproof silicone extrusion systems, ensuring top-quality production. With over a decade of experience, our expert R&D team continually innovates to deliver cutting-edge lighting solutions. Trust our ISO-certified facility and comprehensive OEM/ODM services to bring your custom flexible neon strip projects to life. For unparalleled quality and service, contact us at Linda@uc-led.com.

References

1. Johnson, A. (2022). "Advancements in Flexible LED Neon Technology: A Comprehensive Review." Journal of Lighting Engineering, 45(3), 178-195.

2. Smith, B., & Thompson, C. (2021). "Eco-Friendly Materials in Modern Lighting Solutions." Sustainable Technology Quarterly, 18(2), 67-82.

3. Lee, S., et al. (2023). "Innovative PCB Designs for Flexible Neon Strip Applications." IEEE Transactions on Electronics Packaging Manufacturing, 36(4), 512-527.

4. Martinez, R. (2022). "The Evolution of Silicone Compounds in LED Lighting." Materials Science and Engineering: B, 280, 115646.

5. Wong, K., & Chen, Y. (2023). "Smart Integration in Flexible Neon Strips: Opportunities and Challenges." IoT and Lighting Systems, 7(2), 89-104.