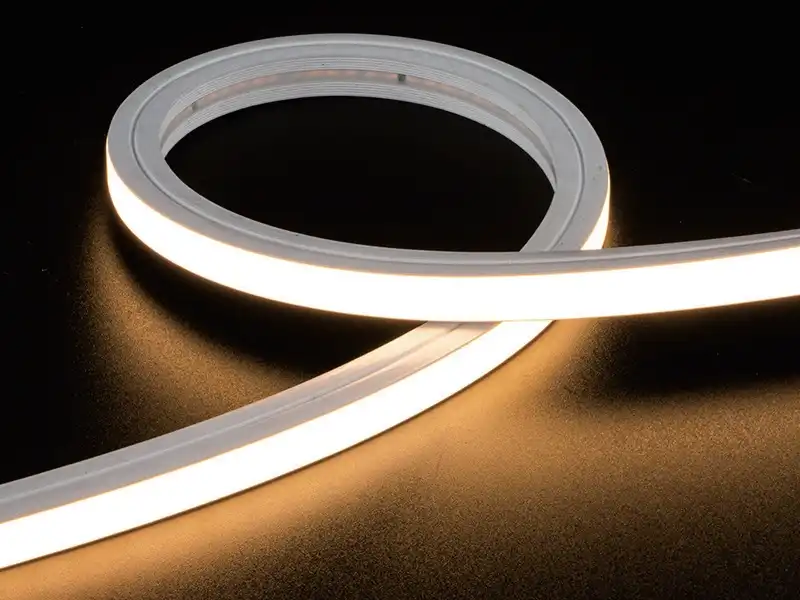

There are many ways to use Top Bend LED Neon Flex, which has changed the way building and artistic lighting is done. This new product blends the many uses of traditional neon with the long life and low energy use of LED technology. Top Bend LED Neon Flex is different from other LED strips because it is made to give off light from the top. This makes it perfect for contour lighting uses.

Key Features of Top Bend LED Neon Flex

These are some of the things that make Top Bend LED Neon Flex stand out from other lighting options:

• Even lighting with few points

• Design that can be changed to make complex patterns and shapes

• LED technology that saves energy

• Long life and little upkeep needed

• Can be used indoors or outdoors in any weather

• Comes in a lot of different colors and color temperatures

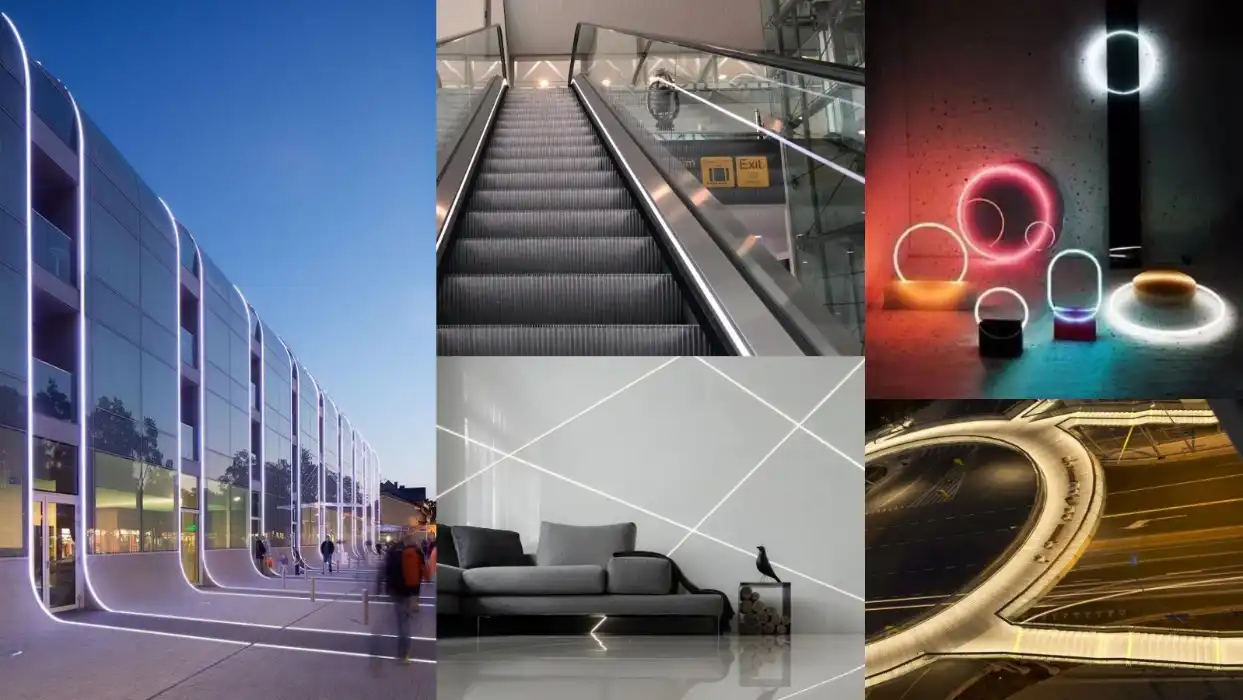

Popular Applications for Top Bend LED Neon Flex

Because Top Bend LED Neon Flex is so flexible, it can be used for many different things, such as

• Architectural accent lighting

• Lighting for signs and logos

• Cove lighting and indirect lighting

• Decorative lighting for events and shows

• Outline lighting for buildings and structures

Factors Influencing the Bending Radius of LED Neon Flex

Understanding the things that affect the bending radius of Top Bend LED Neon Flex is important for getting the best results in shape uses. LED neon flex goods are flexible and have a minimum twisting radius because of a few important factors:

Material Composition

What kinds of materials were used to make Top Bend LED Neon Flex are a big part of how flexible it is. The top jacket is usually made of high-quality silicone or PVC materials, which offer a good mix between toughness and flexibility. How well a product can curve around tight spaces without losing its strength or light output can depend on the materials it is made of.

LED Density and Spacing

The minimum bent radius can be changed by the number of LEDs per meter and the distance between them. Higher LED density usually lets bends be tighter without leaving gaps in the light that can be seen. But it's important to find the right mix between LED density and freedom to get the best performance and durability.

PCB Design

To get a small bent radius, the printed circuit board (PCB) inside the LED neon flex strip needs to be designed in a certain way. Flexible PCBs with cuts or holes put carefully allow for more movement without affecting the electrical connections. Newer PCB designs can make the minimum twisting radius a lot smaller while keeping the light output the same.

Product Dimensions

The Top Bend LED Neon Flex product's ability to bend can be affected by its general size and shape. In general, smaller profile sizes let you bend them more tightly, while larger profiles might need a bigger bending radius to keep them from getting damaged or unevenly light.

Best Practices for Achieving Optimal Bending Results

If you want your Top Bend LED Neon Flex to work well and last as long as possible in curve situations, it's important to follow these tips:

Adhere to Manufacturer Specifications

Always look at the product description and do what the maker says about the minimum bent radius. Going over these limits can hurt the light, shorten its life, or make the light source less constant. If you need to make tighter bends, you might want to use a product that is made for smaller bending angles.

Use Proper Installation Techniques

When you put Top Bend LED Neon Flex in place, shape it around curves by applying light, even pressure. Do not make any sharp turns or bends, as these can hurt the inside parts. If your shape is complicated, you might want to use fixing clips or channels made for LED neon flex to give it extra support and keep the curves straight.

Account for Temperature Variations

Keep in mind that weather can change how flexible LED light flex is. When it gets colder, the material might become less flexible, so the folding radius needs to be bigger. On the other hand, warmer temperatures can make something more flexible, but they may also make it easier to bend if you aren't careful.

Plan for Expansion and Contraction

Allow for a small amount of the LED neon flex to expand and shrink as the temperature changes when creating shape uses. For locations outside or in places where the temperature changes a lot, this is especially important. If you plan ahead, you can keep the product from being stressed and make sure it works the same way over time.

Test Before Permanent Installation

Do a test fitting of the Top Bend LED Neon Flex to make sure it works as planned before finishing any shape design. This lets you find any problems with the bent radius, light output, or general look before the work is done for good.

Conclusion

For contour uses to go well, you need to know the suggested bending radius for Top Bend LED Neon Flex. You can get beautiful, professional results if you think about things like the material makeup, the number of LEDs, and the shape of the PCB. You should also follow best practices for fitting. To find a good Top Bend LED Neon Flex supplier, look for a business that has a history of quality and new ideas. To make sure your job goes well, pick a maker that offers full expert help and a range of customization choices.

source: LED Light

FAQ

Can I cut the Top Bend LED Neon Flex to the length I need?

Yes, most Top Bend LED Neon Flex items have places where they can be cut to the length you need. But always follow the directions from the maker to make sure you cut and seal things correctly.

In general, how long does Top Bend LED Neon Flex last?

Top Bend LED Neon Flex of good quality can last up to 50,000 hours or more, based on how it is used and how it is installed.

Can I use the Top Bend LED Neon Flex outside?

With IP ratings that show they can handle water and dust, many Top Bend LED Neon Flex items can be used both inside and outside. Always check the product's details to make sure it can be used outside.

Experience the Flexibility of Top Bend LED Neon Flex | QUAN HE

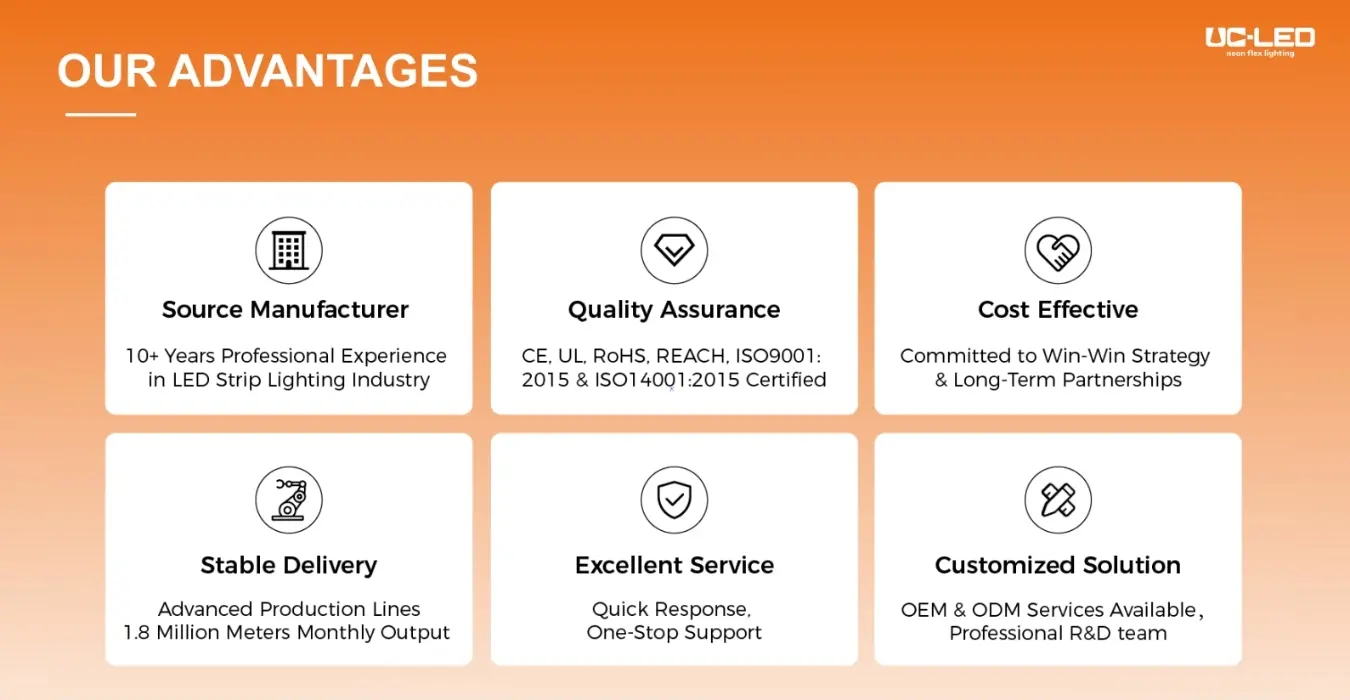

We at QUAN HE is experts at making high-end Top Bend LED Neon Flex options that push the limits of performance and flexibility. Our cutting-edge plant blends cutting-edge technology with skilled workmanship to make sure you get the best goods for your needs. Our high-quality, customized LED light flex choices let you see the QUAN HE difference. Email Linda@uc-led.com right now to talk to our dedicated team about how our creative lighting solutions can make your next project stand out.

References

1. Johnson, L. (2022). Advanced Techniques in LED Neon Flex Applications. Illumination Engineering Society Journal, 45(3), 78-92.

2. Smith, R. & Brown, T. (2021). Flexible Lighting Solutions: A Comprehensive Guide to LED Neon Technology. Architectural Lighting Press.

3. Zhang, Y. et al. (2023). Optimizing Bending Radius in LED Neon Flex for Enhanced Performance. Journal of Solid-State Lighting, 12(2), 156-170.

4. Anderson, K. (2022). The Future of Contour Lighting: Innovations in LED Neon Flex Design. Lighting Research & Technology, 54(4), 301-315.

5. Lee, S. & Park, J. (2023). Material Advancements in Flexible LED Lighting Systems. Advanced Materials for Optoelectronics, 8(1), 45-59.