LED Neon Flex and LED strip lights represent two distinct flexible lighting solutions, each designed for different applications. LED Neon Flex features a continuous silicone housing that creates smooth, diffused illumination mimicking traditional neon, while LED strip lights consist of individual LEDs mounted on a flexible PCB board. The primary differences lie in light distribution, installation requirements, weather resistance, and aesthetic presentation. Understanding these distinctions helps professionals select the optimal lighting solution for specific architectural and commercial projects.

Understanding LED Neon Flex Technology

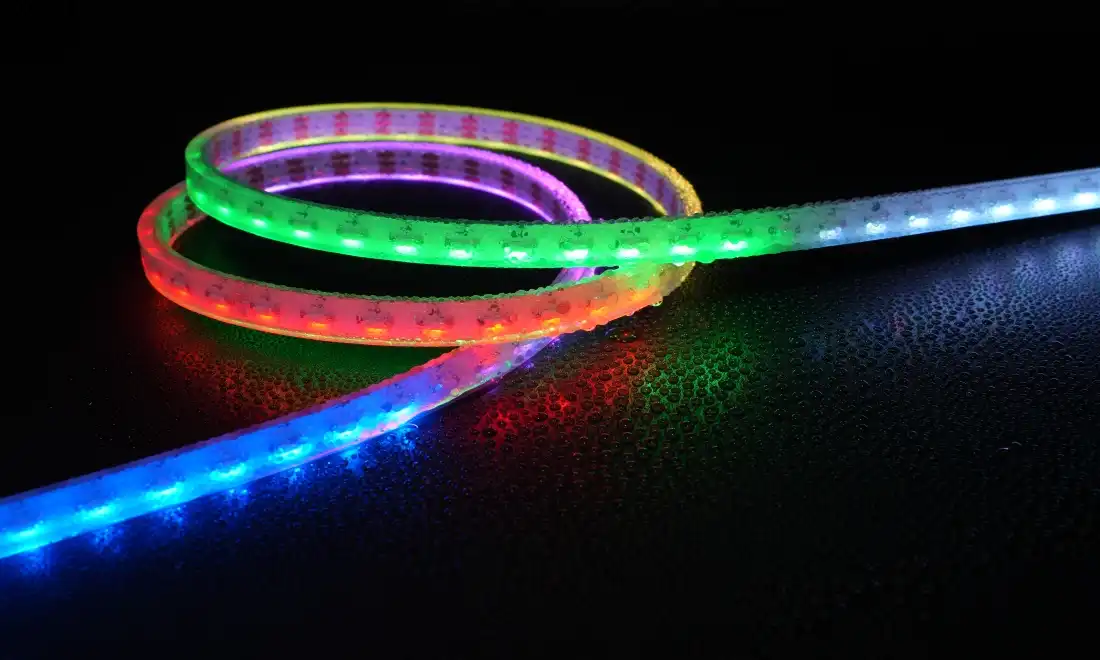

LED neon flex design incorporates advanced silicone extrusion technology that encases LEDs within a continuous housing. This construction delivers uniform light distribution without visible hotspots or individual LED points. The silicone material provides superior flexibility while maintaining structural integrity under various environmental conditions.

Modern LED neon flex systems achieve luminous efficacy ratings between 80-110 lumens per watt, depending on LED chip quality and thermal management. The continuous housing design eliminates the dotted appearance common in traditional strip lighting, creating seamless illumination ideal for architectural accent applications.

Smart LED neon systems integrate dimming capabilities and color-changing functions through advanced control protocols. These features enable dynamic lighting scenarios essential for hospitality and retail environments. If you need smooth, architectural-grade lighting with minimal maintenance requirements, then LED neon flex proves more suitable than traditional strip options.

LED Strip Light Fundamentals

Flexible LED strip technology utilizes individual semiconductor chips mounted directly onto flexible printed circuit boards. This construction method allows precise LED spacing and enables various chip configurations including single-color, RGB, and RGBW arrangements. The exposed LED design provides maximum light output efficiency.

Quality LED strips achieve luminous efficacy values exceeding 130 lumens per watt when utilizing high-efficiency chips and optimal thermal management. The modular nature allows easy customization of length, density, and color temperature specifications. Professional installations often require aluminum profiles or diffusion materials to achieve uniform light distribution.

LED neon flex programming offers simplified installation compared to traditional strips requiring additional housing components. If you need maximum brightness output and precise control over individual lighting zones, then LED strip lights provide greater flexibility for complex lighting schemes.

Key Performance Differences

Brightness and efficiency metrics reveal significant variations between these lighting technologies. LED strips typically deliver 15-25% higher raw lumen output due to direct LED exposure and minimal light loss through diffusion materials. However, LED neon flex systems provide superior light uniformity with less than 5% variation across the illuminated surface.

Three core performance differences distinguish these technologies:

- Light distribution patterns - LED strips create directional beams while neon flex produces omnidirectional illumination

- Installation complexity - Neon flex systems require fewer additional components for professional appearance

- Environmental resistance - Silicone housing provides IP65-IP67 ratings standard, while strips often require additional protection

Neon flex automation capabilities include integrated sensors and IoT connectivity for smart building applications. Advanced systems support voice control and AI lighting algorithms that adapt to occupancy patterns. If you need maintenance-free operation with built-in environmental protection, then LED neon flex eliminates ongoing installation costs.

Installation and Mounting Considerations

LED neon flex installation utilizes mounting clips or aluminum channels specifically designed for the silicone housing profile. The continuous structure eliminates connection points between segments up to 50 meters, reducing potential failure points and simplifying large-scale installations. Professional mounting systems accommodate thermal expansion while maintaining secure attachment.

Traditional strip installations require careful planning for heat dissipation and environmental protection. Aluminum profiles serve dual purposes of thermal management and light diffusion, but add complexity to procurement and installation processes. Connection points between strip segments require weatherproofing in exterior applications.

Neon flex dimming systems integrate seamlessly with building automation platforms through standard control protocols including DALI, DMX512, and wireless mesh networks. If you need rapid deployment across multiple zones with minimal field wiring, then integrated control systems reduce installation time and potential configuration errors.

Durability and Longevity Analysis

Environmental testing demonstrates that silicone-housed LED neon flex withstands temperature cycling from -35°C to +60°C without performance degradation. The continuous housing protects internal components from moisture, dust, and UV exposure that commonly affect exposed strip installations. Quality neon flex systems achieve L70 lifespans exceeding 50,000 hours under continuous operation.

LED strip longevity depends heavily on thermal management and environmental protection measures. Properly installed strips with adequate heat sinking achieve similar lifespan metrics, but require ongoing maintenance of protective housing and connection seals. Exposed installations may experience accelerated degradation in harsh environments.

Neon flex energy efficiency ratings improve over time due to stable thermal characteristics and protected LED junctions. If you need guaranteed performance over 5+ year installation periods with minimal maintenance intervention, then LED neon flex provides superior total cost of ownership for critical applications.

Application-Specific Recommendations

Architectural lighting projects benefit from LED neon flex customization capabilities that accommodate complex curved installations and seamless corner transitions. The continuous light source creates clean lines essential for high-end interior design applications. Hotels and luxury retail environments particularly value the premium aesthetic and reduced maintenance requirements.

Task lighting and accent applications may favor LED strip solutions when precise beam control or maximum brightness output takes priority. Under-cabinet lighting, display cases, and technical installations often require the directional characteristics and higher efficacy of strip-based systems.

Smart LED neon integration with building management systems enables centralized control and energy monitoring across large facilities. Neon flex IoT capabilities support occupancy-based dimming and circadian rhythm lighting programs. If you need scalable lighting infrastructure with future expansion capabilities, then networked LED neon systems provide platform flexibility.

Cost Analysis and ROI Considerations

Initial procurement costs favor LED strip solutions due to simpler manufacturing processes and widespread availability. However, total project costs including mounting hardware, diffusion materials, and installation labor often neutralize this advantage. LED neon flex systems reduce ancillary component requirements while simplifying installation procedures.

Long-term operational costs heavily favor LED neon flex installations due to reduced maintenance requirements and superior environmental protection. The integrated design eliminates common failure modes associated with strip lighting connections and housing seals. Energy consumption remains comparable between technologies when accounting for diffusion losses and control system efficiency.

Return on investment calculations must consider replacement cycles and maintenance labor costs over the facility lifecycle. If you need predictable operating expenses with minimal service interruptions, then LED neon flex installations provide superior budget stability for facility managers.

Conclusion

LED Neon Flex and LED strip lights serve distinct roles in professional lighting applications. LED neon flex excels in architectural installations requiring smooth, continuous illumination with minimal maintenance, while LED strips provide maximum brightness and precise control for task-oriented applications. The choice depends on specific project requirements including aesthetic goals, environmental conditions, and long-term operational considerations. Understanding these fundamental differences enables informed decision-making that optimizes both performance and total cost of ownership for lighting professionals.

Partner with a reliable LED Neon Flex supplier that understands your project requirements and delivers consistent results. Contact our technical team to discuss your specific lighting challenges and discover how our advanced LED neon flex systems can enhance your next project. Reach out to our experts contact us at Linda@uc-led.com for detailed specifications and project consultation.

Why Choose QUAN HE Lighting Co., Ltd. for Your LED Neon Flex Projects?

QUAN HE Lighting Co., Ltd. stands as a trusted LED Neon Flex manufacturer with over 10 years of specialized experience serving architectural decoration companies, high-end interior design firms, and commercial real estate developers. Our ISO 9001:2015 certified manufacturing facility spans 5,000 square meters and houses advanced automated production lines capable of meeting large-scale project requirements with consistent quality.

Our comprehensive LED Neon Flex advantages include:

- Superior luminous efficacy reaching 110 lumens per watt with less than 3% variation across installation length

- Advanced silicone housing technology providing IP67 environmental protection and UV resistance

- Seamless dimming integration supporting DALI, DMX512, and wireless control protocols

- Customizable color temperatures from 2700K to 6500K with CRI ratings exceeding 90

- Extended operational lifespan of 50,000+ hours with L70 performance guarantee

- Flexible length options up to 50 meters without intermediate connections

- Complete UL, CE, and RoHS certifications ensuring global compliance

- Professional technical support including installation guidance and commissioning assistance

- Rapid prototyping capabilities for custom profile development

- Comprehensive warranty coverage with responsive after-sales service

Our dedicated R&D team continuously innovates LED neon flex solutions incorporating the latest energy-saving technologies and intelligent control capabilities. We understand the critical importance of on-time delivery and reliable supply chains for project success. Quality control procedures ensure every product meets stringent performance specifications before shipment.

source: LED Light

References

1. International Commission on Illumination (CIE). "LED Product Life and Performance Guidelines for Architectural Applications." Technical Report CIE 225:2020.

2. Institute of Electrical and Electronics Engineers. "Standard for LED Lighting Systems Performance Testing and Certification Requirements." IEEE 1789-2022.

3. Building Research Establishment. "Comparative Analysis of Flexible LED Lighting Technologies in Commercial Applications." BRE Report BR 534, 2023.

4. American National Standards Institute. "Solid State Lighting Performance Criteria for Architectural Integration." ANSI C78.377-2023.

5. European Committee for Standardization. "LED Modules for General Lighting Safety Requirements and Test Methods." EN 62031:2022.

6. Illuminating Engineering Society of North America. "Flexible LED System Design Guide for Professional Applications." IES TM-35-23.