The Evolution of Neon Lighting: From Glass Tubes to LED Neon Flex

The switch from regular neon lights to LED Neon Flex shows how lighting technology has improved. Glass tubes filled with neon gas were used to make neon lights for the first time in the early 1900s. The glow of neon signs comes from the gas molecules being excited by an electric current that ran through these tubes.

Some things are bad about old neon lights, even though they are cute. There are dangerous things inside that make them weak and energy-hungry. Making complicated shapes out of glass tubes is also a lot of work that requires skilled craftsmanship.

These issues can now be solved with LED Neon Flex, a new product that still looks like neon lights. This modern choice has Light Emitting Diodes (LEDs) inside a frame that can be bent and lasts a long time. It looks like traditional neon but has many advantages.

Advantages of LED Neon Flex over Traditional Neon

• Energy Efficiency: LED Neon Flex uses a lot less power than normal neon. This means it costs less and helps the environment less.

• Durability: LED Neon Flex is very hard to break because its body is made of flexible PVC or rubber, while glass neon tubes are easy to break.

• Versatility: Because LED Neon Flex is bendable, it can be easily put up in a variety of shapes and sizes. This makes it possible for artists to use lights in new ways.

• Safety: LED Neon Flex is safer for both home and business use because it runs on low voltage and doesn't have any harmful gases in it.

• Longevity: A LED Neon Flex light can last up to 50,000 hours longer than a normal neon light, which means it costs less to fix and keep up.

It was a big step forward in lighting technology when neon tubes were switched out for LED Neon Flex. Not only does it look like neon, but it also has the perks of modern LED technology. It's a useful and eco-friendly way to light up the 21st century.

The Inner Workings of LED Neon Flex: A Closer Look

To fully appreciate how clever LED Neon Flex is, you need to know what its parts are and how they fit together to make it glow like neon. Let's look more closely at how this lighting choice works right now.

Key Components of LED Neon Flex

1. LED Chips: LED Neon Flex works because of the LED chips. These very small semiconductors give off light when electricity runs through them. Most of the time, the chips are row-wise along a circuit board that can be bent.

2. PCB that can change shape: The LED chips are put on a PCB that can change shape. This PCB powers the LEDs and also lets the whole strip bend and flex.

3. Phosphor Coating: In many LED Neon Flex products, a phosphor coating is put on the LED chips. This cover can be used to change the color of the light that is given off and to help it spread out.

4. Silicone or PVC Case: An LED strip is covered by a clear, bendable tube made of silicone or PVC. This case does several things:

• It protects the electronics and LEDs from dust, water, and physical damage

• it spreads the light from the LEDs so the neon glow is more even

• it makes the LED Neon Flex bendable so it can be shaped in different ways.

5. Power Source: The LED Neon Flex needs low voltage DC power, usually 12V or 24V, to work. There is a power source box that changes the AC power from the wall plug to the right DC energy.

How LED Neon Flex Produces Light?

The way LED Neon Flex lights up is a fun mix of materials science and electricity:

1. The LED chips on the bendable PCB get power when it is plugged into a power source.

2. Electricity moves electrons around in the LED's semiconductor material when it runs through it. This gives off energy in the form of light. This is one way to make electric light.

3. The color of the light an LED chip gives off is based on the semiconductor materials that are used to make it. There are many places where colors come from.

4. If the cover is made of phosphor, it may take some of the light that the LED sends out and send it back out at a different range. This could change the color that is seen.

5. The light then passes through the PVC or plastic case, which makes it brighter and more neon-like.

It makes a bright, straight line of light that looks like regular neon but works better, lasts longer, and is easier to bend. LED Neon Flex stays cool to the touch because LEDs don't give off much heat. This makes it safer for many uses.

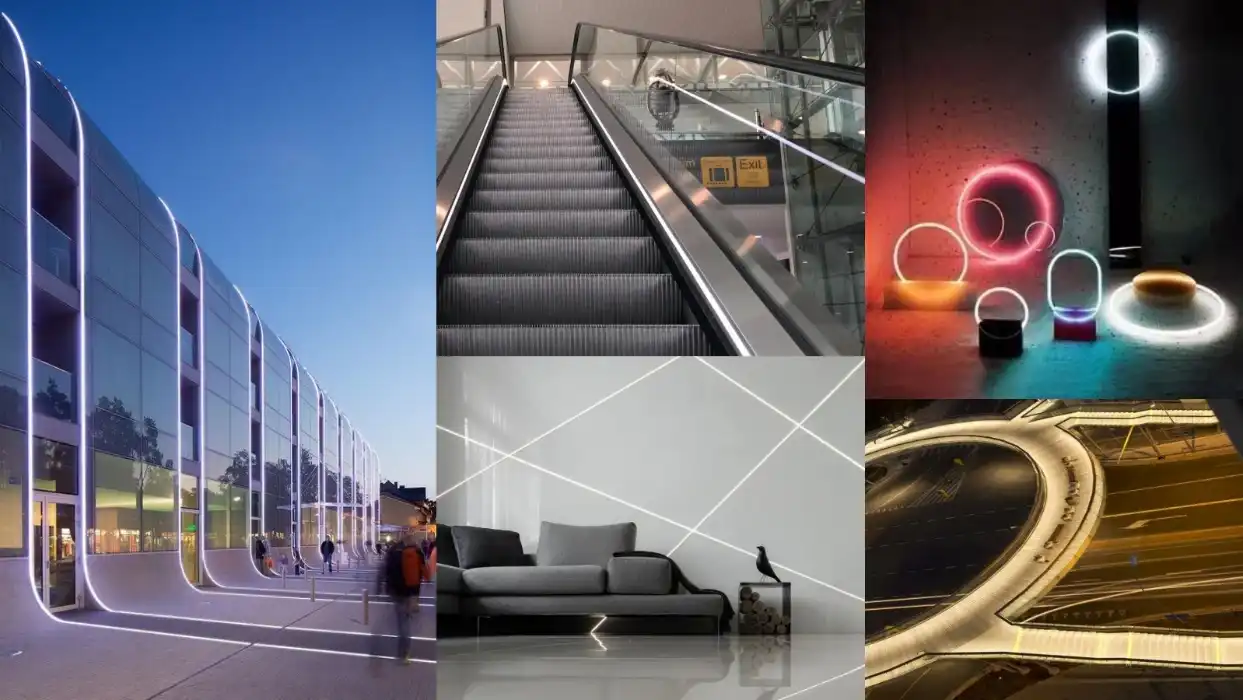

Applications and Installation of LED Neon Flex: Illuminating Possibilities

A lot of people choose LED Neon Flex for lighting jobs because it looks good and can be used in a lot of different ways. This type of lighting is very flexible and can be used for many creative projects, from business signs to home decor. First, let's talk about some common ways to use LED Neon Flex and where to put it.

Common Ways to Use LED Neon Flex

• Commercial Signage: LED Neon Flex is often used for shop signs, name displays, and store window decorations for the holidays. As night falls, its bright glow helps businesses stand out.

• Architectural Lighting: Architects and designers use LED Neon Flex to draw attention to parts of buildings, make structures stand out, or set dramatic lighting effects on the outside of buildings.

• Event Decor: LED Neon Flex is often used for short-term setups at parties, weddings, and other events because it is flexible and easy to set up.

• For interior design, LED Neon Flex is used to add accent lighting, set the scene, or just make a space look nice.

• Making cars look unique: car fans use LED Neon Flex to add underglow effects or accent lighting to their cars.

• Art displays: Artists use LED Neon Flex to make statues and interactive displays because it is bendable and comes in different colors.

Installation Process for LED Neon Flex

It's not hard to set up LED Neon Flex, but you need to make sure you do it the right way for safety and the best results:

1. Make a plan: Make a plan for how the LED Neon Flex will be set up and measure the area where it will go. Check to see where the power sources are and if the design has any turns or curves.

2. Most of the time, LED Neon Flex can be cut to the length you need in certain places. To keep it waterproof, always cut at a 90-degree angle and seal the end.

3. Putting it together: You can put LED Neon Flex in a few different ways:

• Mounting clips: Setting clips are made of plastic and can be attached to the surface with glue or screws. After that, the LED Neon Flex snaps into place.

• Aluminum channels: Putting the LED Neon Flex into a metal tube and then attaching it to the surface will give it a cleaner look.

• Sticky back: Some LED Neon Flex items have a sticky back that lets you stick them to surfaces right away.

4. Wiring: Connect the LED Neon Flex to the power source. Make sure that all of the links work properly and are safe.

5. Setting up the power source: Make sure the power source is dry and easy to get to. To make sure it can handle all of your LED Neon Flex's power, you should test it.

6. Try it out: Before you finish setting up the LED Neon Flex, make sure that all of its parts work well and that the result is what you want.

When you put LED Neon Flex somewhere, you should think about what's around it. A lot of things can be used outside, but they might need extra safety in bad weather. Always follow the directions that came with the product for how to set it up and use it.

Along with being flexible in how it looks, LED Neon Flex is also flexible in how it can be used. This type of lighting is very adaptable; it can be used to make a home feel cozy or to make shows for businesses that stand out. It keeps giving us new ways to build and create things.

Conclusion

Light technology has come a long way since the LED Neon Flex. Instead of bright lights, it's more current, uses less energy, and can be used in different ways. It can be used for many things, from business signs to art pieces, because it is bendable, strong, and gives off bright, even light.

We've seen that LED Neon Flex works by cleverly mixing LED technology with fabrics that are bendable and spread light. This makes a product that looks like regular neon but is safer, uses less energy, and lasts longer, among other things.

Find a reputable LED Neon Flex manufacturer or supplier if you want to use this new kind of lighting in your projects. Find businesses that sell good things, let you change them, and have great customer service. You can make your lighting dreams come true by using the right LED Neon Flex product and putting it up in the right way. It will give you amazing effects that will amaze and inspire people.

source: LED Light

FAQ

How long does LED Neon Flex last in general?

The best LED Neon Flex can last up to 50,000 hours, which is more than 5 years of continuous use.

How much power does LED Neon Flex use?

Yes, LED Neon Flex uses very little power. It uses a lot less power than standard LED lights.

Can I use LED Neon Flex outside?

The IP ratings on many LED Neon Flex items make them safe for use outside. They keep out dust and water. Pay attention to what the maker says at all times.

Is there a way to dim the LED Neon Flex?

Many LED Neon Flex things can be dimmed with dimming tools that are made to work with them.

Professional LED Neon Flex Solutions | QUAN HE

QUAN HE Lighting Co., Ltd. was established in 2015 and is a leading manufacturer of high-end linear lighting products, such as LED Neon Flex. Our 5,000m² plant has the most up-to-date technology. It has advanced SMT manufacturing lines and strict processes for checking the quality. People can bring their own lighting ideas to life with our skilled OEM and ODM design services. If you need LED Neon Flex, you can trust QUAN HE. We care about new ideas, good quality, and making sure our customers are happy. Send us an email at Linda@uc-led.com to learn how our workshop can help you with your projects by giving you choice of high-quality LED Neon Flex.

References

1. Johnson, A. (2022). "The Evolution of Neon: From Glass Tubes to LED Technology". Lighting Science Quarterly, 45(2), 78-92.

2. Smith, R. & Lee, K. (2021). "Energy Efficiency in Modern Lighting: A Comparative Study of LED Neon Flex and Traditional Neon". Journal of Sustainable Lighting, 16(3), 205-220.

3. Patel, N. (2023). "Applications of LED Neon Flex in Architectural Design". Architectural Lighting Review, 38(1), 42-56.

4. Chen, L., et al. (2020). "Material Advancements in LED Neon Flex Technology". Advanced Materials for Optoelectronics, 12(4), 1235-1250.

5. Williams, T. (2022). "Installation Techniques and Best Practices for LED Neon Flex". Professional Electrician's Handbook, 7th Edition, Chapter 15, 412-430.