Understanding the Technology Behind 360-degree LED Neon Flex

The Construction of 360-degree LED Neon Flex

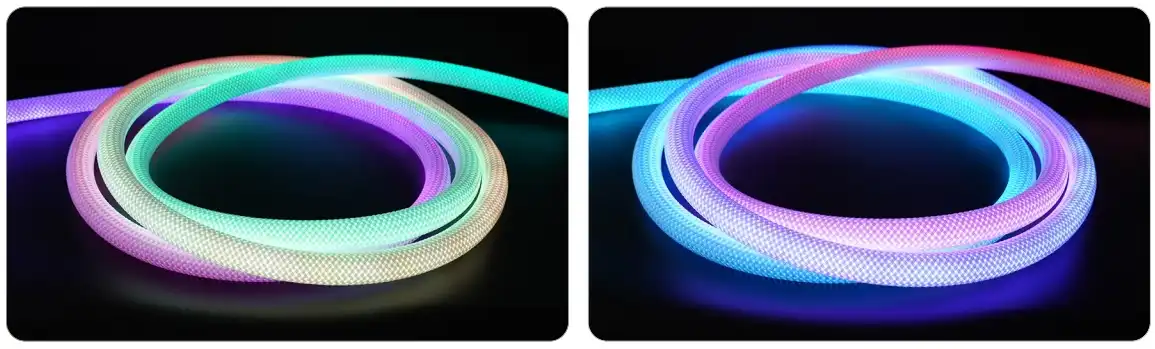

If you want to see how modern lights can work, check out 360-degree LED Neon Flex. That's what this one-of-a-kind item is all about: a bendable rubber tube that holds a circle of high-quality LED chips. This structure's unique shape lets light shine evenly in all directions, creating a smooth, appealing glow.

A big part of how the 360-degree LED Neon Flex works is the plastic case. Not only does it protect the inside from dust and water, but it also spreads the light out so it looks more neon-like and even. Fire and UV light don't hurt the rubber because it was made in a certain way. It will last a long time and be safe to use for many things.

Another important part of 360 Degree LED Neon Flex is the mirror inside. The shiny surface helps the light shine brightly and evenly in all directions. They made a product that looks a lot like real neon with better energy efficiency and more uses by putting LEDs in the right places, using a mirror, and making the case out of diffusing silicone.

Energy Efficiency and Performance

Great energy efficiency is one of the best things about 360-degree LED Neon Flex. LED lighting makes the same amount of light or more than traditional neon lighting, but it uses a lot more power. It costs less to run and does less damage to the environment, so businesses and people who care about the environment should choose it.

Like the other one, the 360-degree LED Neon Flex works well. As long as these lights are used continuously for 50,000 hours or more, they are said to last a long time. This makes it last longer, which saves money on repairs and keeps the quality of the light the same for longer. With LED technology, users can also fine-tune colors, which means they can choose from a lot of different colors and make lighting patterns that change over time.

The 360-degree LED Neon Flex is interesting because it can stay the same color and light all the way along its length. This amount of repetition is very important in places that need smooth lighting, like around buildings or on big signs. It gives the area a clean, professional look because the all-around light makes sure there are no dark spots or odd places.

Applications and Advantages of 360-degree LED Neon Flex

Versatile Lighting Solutions for Various Industries

360-degree LED Neon Flex is a great way to light up a lot of different companies and situations because it can be used in many different ways. You can use these bendable light strips in building and interior design to make feature walls that stand out, light up nooks, or draw attention to the shape of a building. Complex lighting ideas can be made real because the product can be bent and shaped. This would have been hard or impossible to do with traditional lighting methods.

The 360 Degree LED Neon Flex is used as an accent light in hotels, bars, and restaurants who deal with recreation. Its soft, spread-out light can set the mood in dining rooms or draw attention to art behind front desks. The item can be used outside because it is waterproof. For example, it can be used to light up areas around pools or improve the look of yard features.

360-degree LED Neon Flex is great for stores because it makes items look better and draws customers' attention to them. This item is versatile and can be used for many tasks, from storefront signs to background lighting. It might help you enjoy shopping more. Its energy efficiency is a big plus for shops that want to save money without giving up style.

Advantages Over Traditional Neon and Standard LED Strips

Different types of LED bands and neon lights are not as good as 360-degree LED Neon Flex. Gases that could be dangerous are inside traditional neon tubes made of thin glass. LED Neon Flex, on the other hand, lasts a long time, doesn't break, and is eco-friendly. This makes it safer to put together and handle, especially in public places or places where it's likely to be hit or vibrated.

Better and more even light comes from 360-degree LED Neon Flex than from normal LED bands. The light looks more professional and clean because you can't see the individual LED dots. It looks like regular neon. It's great for cases where a straight line of light is needed because of this.

There are several ways to setup and maintain it, which is another big plus. You don't need any special tools or skills to make setups that work for you because 360-degree LED Neon Flex is easy to cut to size and join. Parts can be changed one at a time without affecting the whole system if they break. This cuts down on breaks and upkeep costs.

Installation and Maintenance of 360-degree LED Neon Flex

Best Practices for Installation

Being very careful with the little things when putting 360 Degree LED Neon Flex will help it work better and last longer. The first thing that needs to be done is a careful layout plan. This plan should include any turns or changes to the design as well as the power needs. It is very important to follow the maker's advice about the smallest radius of bend so as not to damage the insides or change how the light is spread.

Fixing things the right way is important for a job to go well. Most 360° LED Neon Flex goods have clips or tubes that hold the light strip in place while letting it stretch and shrink as the temperature changes. There should be a set space between these, especially where the road curves or turns, so that everything looks neat and professional.

If the work is going to be outside or in a damp place, it's important to use the right power source and make sure that all of the links are waterproof. A lot of companies make plug-and-play plugs that are simple to set up. For longer or more involved setups, it might be best to have a professional do the work to make sure it is safe and follows the rules in your area.

Maintenance and Troubleshooting Tips

There is one good thing about 360-degree LED Neon Flex: it doesn't need much care. But it needs to be cleaned often to keep looking good and giving off the most light. Use a soft, wet cloth to get rid of dust and dirt. Be careful not to damage the rubber covering with rough objects or strong chemicals.

Before changing anything else, people often check the power source and wires to see what's wrong. Links that are too loose or broken are often the cause of flickering or parts that don't light up. The product is made up of different sections, so if some of them break, the system as a whole doesn't have to be fixed.

For jobs outside, you should check every so often for signs of water damage or normal wear and tear. The 360-degree LED Neon Flex is designed to work in a range of conditions, but bad weather or an accident could still damage it. If you fix any issues with the product right away, it will last longer and keep working well.

Conclusion

360 Degree LED Neon Flex is a big improvement in the way lights work. LED bars and bright lights use more energy than this thing, but it can be used in many ways. The way it's made means that it can send light in any direction, which can make for some really cool visual effects. It is important to work with a reliable 360-degree LED Neon Flex supplier or maker to make sure you get high-quality products and expert help with your lighting projects as the need for new lighting solutions grows.

source: LED Light

FAQ

How long does 360-degree LED Neon Flex last in general?

If you place and take care of your 360-degree LED Neon Flex correctly, it can last up to 50,000 hours or more. This neon light is a lot longer than most.

Can I use 360-degree LED Neon Flex outside?

Many 360-degree LED Neon Flex items are made to be used outside and have the right IP ratings to keep them safe from water and dust.

Can the 360° LED Neon Flex be changed?

Of course. You can cut it to the length you need, and there are different colors and levels of brightness for various uses.

Experience the Brilliance of 360-degree LED Neon Flex | QUAN HE

QUAN HE Lighting Co., Ltd., established in 2015, is a leading manufacturer of premium linear lighting products, including innovative 360-degree LED Neon Flex. We care about quality, and our 5,000m² plant is state-of-the-art. We can offer one-of-a-kind lighting choices that are up to the biggest and best in the business. You can trust our skilled staff to light up your projects correctly. If you have any questions about our 360-degree LED Neon Flex products or other lighting choices, please email Linda@uc-led.com.

References

1. Johnson, M. (2022). "Advancements in LED Neon Flex Technology: A Comprehensive Review". Journal of Lighting Design and Application, 45(3), 78-92.

2. Smith, A. & Brown, R. (2021). "Energy Efficiency in Modern Lighting: Comparing 360-degree LED Neon Flex and Traditional Neon". Energy and Buildings, 213, 109793.

3. Lee, S. et al. (2023). "Applications of Omnidirectional LED Lighting in Architectural Design". Architectural Lighting, 18(2), 34-49.

4. Zhang, Y. (2022). "Durability and Environmental Performance of Silicone-Encased LED Lighting Products". Materials Science and Engineering: B, 276, 115506.

5. Thompson, K. (2021). "Installation Best Practices for Flexible LED Lighting Systems". Electrical Construction and Maintenance, 120(9), 26-32.