Introducing LED Neon Flex for Contour Lighting

LED Neon Flex is a big change in the world of contour lighting because it is a flexible and energy-saving choice compared to regular neon tubes. This new lighting idea uses a series of LEDs housed in sturdy, bendable rubber or PVC. This looks like classic neon lighting while being more versatile and lasting longer.

Key Features of LED Neon Flex

LED Neon Flex for Contour Lighting has many benefits that make it a well-liked option for this type of lighting:

Flexibility: Can easily take on different shapes and curves

• Energy efficiency: It uses less power than regular neon.

• Durability: It doesn't break easily and can stand up to bad weather.

• Customization: You can choose from many colors and lighting settings.

• Low maintenance: lasts a long time and doesn't need much care

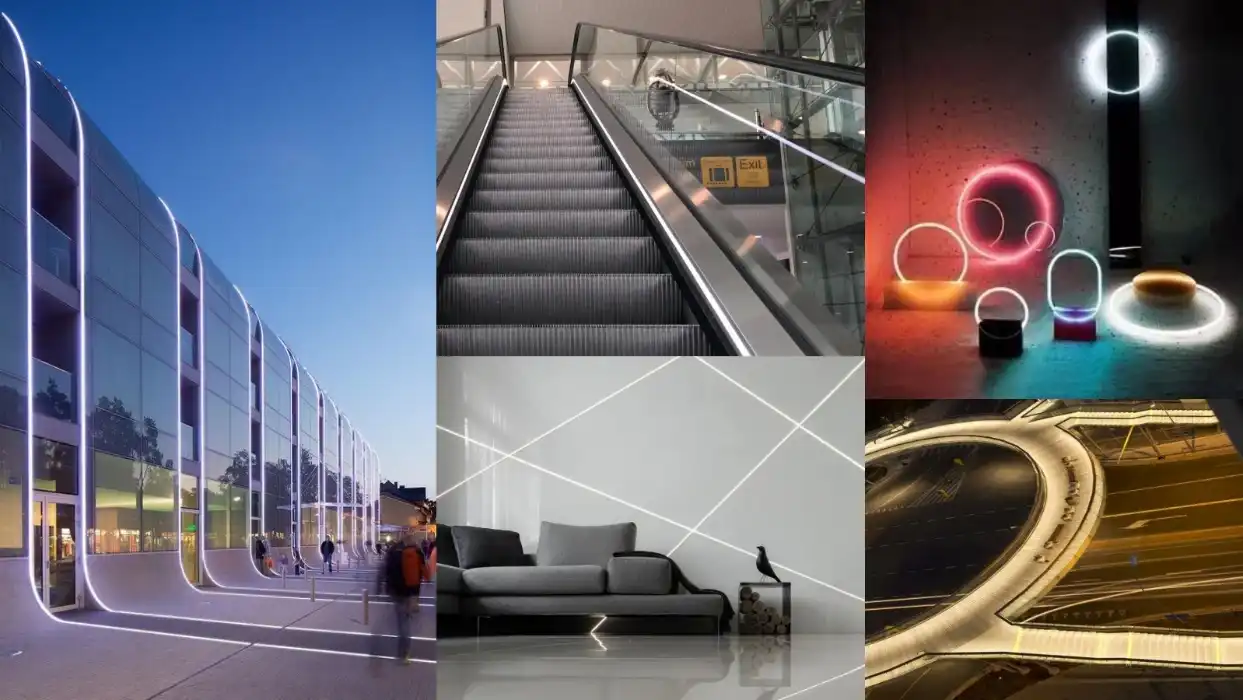

Because of these qualities, LED Neon Flex is great for both indoor and outdoor contour lighting, from adding to the look of a building to using it for signs or other decorations. Because it's so flexible, designers can use it to make the smooth curves, sharp corners, and complex forms that regular lighting can't do.

LED Neon Flex provides long-lasting performance in a variety of settings thanks to its high light, energy efficiency, and resistance to weather, UV, and impact. It also has a lot of different color choices and the ability to lower the lights, which makes it possible to have bright, unique lighting for any task.

Applications of LED Neon Flex in Contour Lighting

There are a lot of different ways to use LED Neon Flex for outline lighting because it is so flexible.

• Architectural highlighting: Architectural highlighting adds to the look of building exteriors and structural features.

• Signage: Signage makes business signs that are eye-catching and lit up.

• Interior design: Interior design makes homes and business spaces more inviting.

• Event décor: Event decor makes places for parties and special occasions look better.

• Landscape lighting: making the edges of paths, yard features, and buildings clear

LED Neon Flex is so flexible that designers and builders can use it to make everyday areas look amazing. Because it is flexible and bendable, it can make designs, forms, and lines that are more complex, smooth, and unique than what is possible with standard lights.

It lets you create unique lighting designs that can fit any theme or mood because it comes in different colors, brightness levels, and dimmer settings. These artistic works stay bright and dependable over time, both indoors and outdoors, thanks to their sturdiness, weather resistance, and energy efficiency.

Factors Influencing Brightness and Color Temperature Selection

There are a few important things to think about when choosing the best brightness and color temperature for LED Neon Flex in contour lighting:

Environmental Factors

The world around you is very important in figuring out the best lighting and color temperature.

• The amount of light in the area: You may need higher lumen rates in brighter places to make sure you can see.

• The reflection of the surface: Surfaces that are light in color reflect more light, which might mean that you need lower brightness levels.

• Viewing distance: It might be necessary to make the screen brighter if it is far away to see it clearly.

• Weather: Installations that are outside might work better with changeable light so they can work in different weather situations.

Looking at these external factors helps to find the best color temperature and brightness for every installation of LED Neon Flex for contour lighting. By thinking about the light in the room, the colors around the object, and the look they want to achieve, artists can make sure that it looks good and works well.

Aesthetic Goals

The brightness and color temperature are chosen based on the look and feel that is wanted:

• Subtle accents: Lower brightness levels make things look more muted and classy.

• Bold statements: More brightness can make shapes stand out and get noticed.

• Warm ambiance: Lower color temperatures (3000K–4000K) make a space feel warm and welcoming.

• Contemporary style: Higher color temperatures (5000K–6000K) give a neat, modern look.

Aligning the brightness and color temperature with the general design idea makes sure that everything goes together and looks good.

Energy Efficiency and Cost Considerations

LED Neon Flex uses energy efficiently, but adjusting light levels can make it even more environmentally friendly and cost-effective:

• Power use: It takes more energy to run higher amounts of light, which affects the cost of running the equipment.

• Dimming: You can change the lighting level to save energy when you don't need the light.

• Lifespan: The product may last longer if it is used at lower light levels.

• Initial investment: LEDs with better color output may cost more at first, but they may be better for you in the long run.

Finding the best answer that looks good and works well depends on finding the right balance between these factors. By carefully thinking about design goals, energy efficiency, longevity, and maintenance needs, builders and designers can make lighting setups that are useful, beautiful, and long-lasting. This all-encompassing method makes sure that everyone is happy and does well.

Optimizing LED Neon Flex Performance for Contour Lighting

To get the most out of LED Neon Flex in contour lighting uses, consider these improvement tips:

Precise Installation Techniques

Installing it correctly is very important for getting the right color temperature and lighting benefits.

• Surface preparation for mounting: Make sure the surface is clean and smooth so that it sticks well.

• Even spacing: Keep the same distance between the LED chips so that the light is even.

• Proper bending: The right way to bend Follow the minimum bent radius guidelines so that no damage occurs.

• Safe links: Use the right connections and seals to keep the weatherproofing up.

Meticulous installation practices contribute to the overall performance and longevity of the LED Neon Flex system. Avoid harm, ensure constant lighting, and keep the sealing intact by carefully attaching and connecting things. Following the manufacturer's instructions and using extras that are known to work with the product lowers the risk of breakdowns or early wear and tear. Plus, making sure everything is lined up and routed correctly makes the overall look better. This level of care ensures the lighting installation's long-term dependability, energy efficiency, and sturdiness.

Control Systems and Dimming

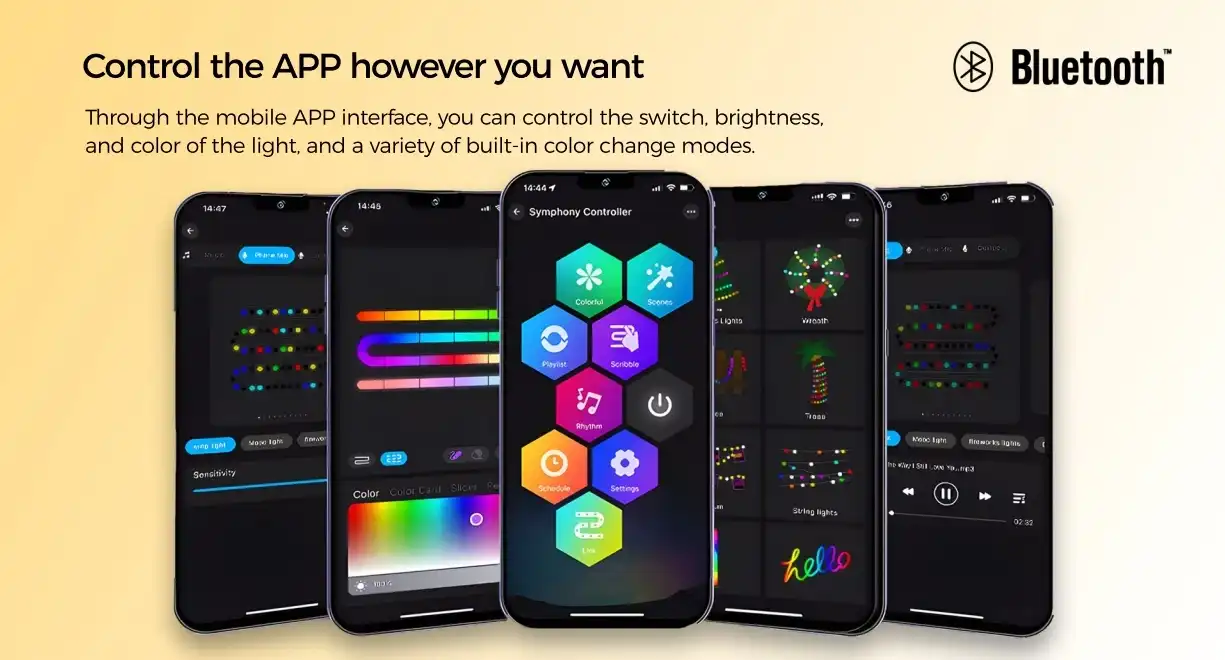

Implementing sophisticated control systems enhances the versatility of LED Neon Flex for contour lighting:

• Programmable controllers: Let you change colors and lighting in real time.

• Motion sensors: Only turn on the lights when someone is there to save energy.

• Time-based scheduling: Automatically change how bright the lights are depending on the time of day or season.

• Remote access: Make changes easily through smartphone apps or central systems.

These controls give you a lot of freedom in how you adjust brightness and color temperature to fit different situations and personal tastes. Users can easily change the amount of light in their spaces to suit their mood, a job, or the time of day, making the environment more lively and individualized. These controls ensure maximum visual comfort, energy efficiency, and artistic effect across home, business, or outdoor setups. They can be used to highlight building features, create mood, or coordinate with other lighting elements.

Regular Maintenance and Monitoring

Regular maintenance makes sure that LED Neon Flex setups work their best and last a long time:

• Regular cleaning: Keep the shine up by getting rid of dust and other junk.

• Inspection routines: Look for signs of damage or wear, especially outside.

• Performance monitoring: Keep an eye on input and output energy to find any problems with efficiency.

• Updates to the firmware Update your control tools regularly so they work better.

A proactive approach to care helps keep the brightness and color temperature that you want for the whole life of the installation. Regular checks, cleaning, and quick replacement of any broken parts make sure that everything works as it should and stops slow dimming or changing of color. This method keeps the lighting system's appearance, energy efficiency, and dependability intact for many years.

Conclusion

It takes careful consideration of a number of different factors to choose the right brightness and color temperature for LED Neon Flex for Contour Lighting uses. By knowing how LED Neon Flex is different and how each installation needs to be done, designers and workers can make beautiful lighting effects that improve any area.

If you want high-quality LED Neon Flex goods and expert advice, you should work with a well-known LED lighting maker. Find companies that have a history of coming up with new ways to use lights, can help you with technology issues, and let you customize your order. The right LED Neon Flex supplier or maker will help you get the best performance from your contour lighting projects. They will help you get the right mix of brightness, color temperature, and general performance.

source: LED Light

Frequently Asked Questions

How long does LED Neon Flex usually last?

Depending on how and where it's used, high-quality LED Neon Flex can last over 50,000 hours.

Can you cut LED Neon Flex to any length you want?

Yes, most LED Neon Flex goods can be cut at certain places along the strip, which are usually marked every few centimeters.

Can LED Neon Flex be used in water?

A lot of LED Neon Flex items come with IP67 or IP68 grades, so they can be used in outdoor and wet settings.

Is it possible to dim LED Neon Flex?

Yes, most LED Neon Flex goods work with a range of dimming systems, which let you change how bright they are.

Experience the Brilliance of Custom LED Neon Flex Solutions | QUAN HE

At QUAN HE, we focus on providing high-quality LED Neon Flex for projects of all sizes that need contour lighting. Our new, high-tech factory and knowledgeable R&D team make sure that we can meet your exact color temperature and brightness needs. We are the best partner for new lighting ideas because of our wide-ranging OEM and ODM services. Feel the difference of working with a top LED Neon Flex maker. Emailing Linda@uc-led.com will help make sure your next job is perfectly lit.