What Are The Waterproofing Processes Used In LED Neon Flex Strip?

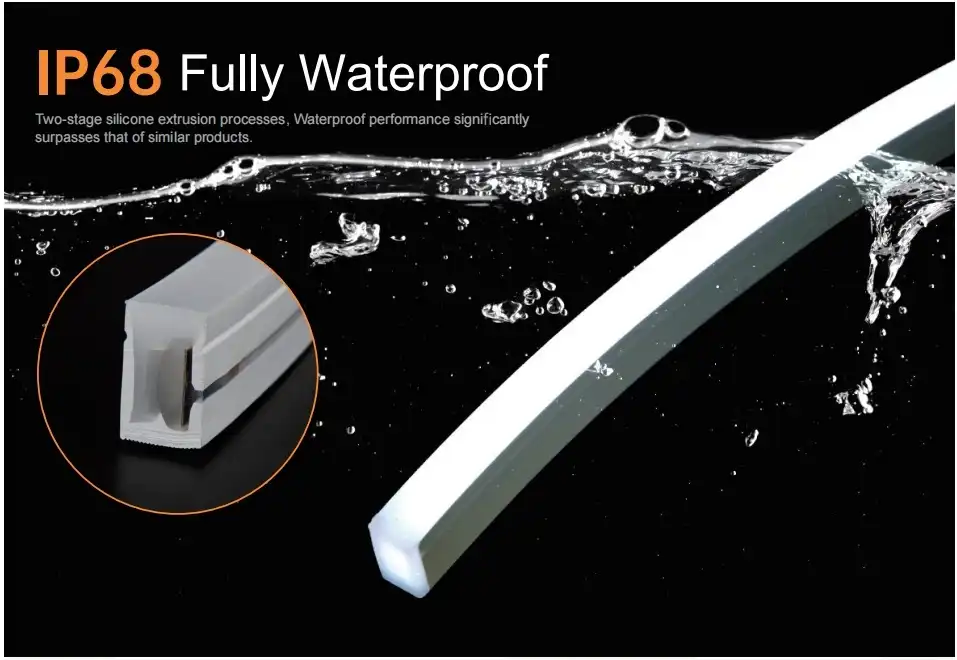

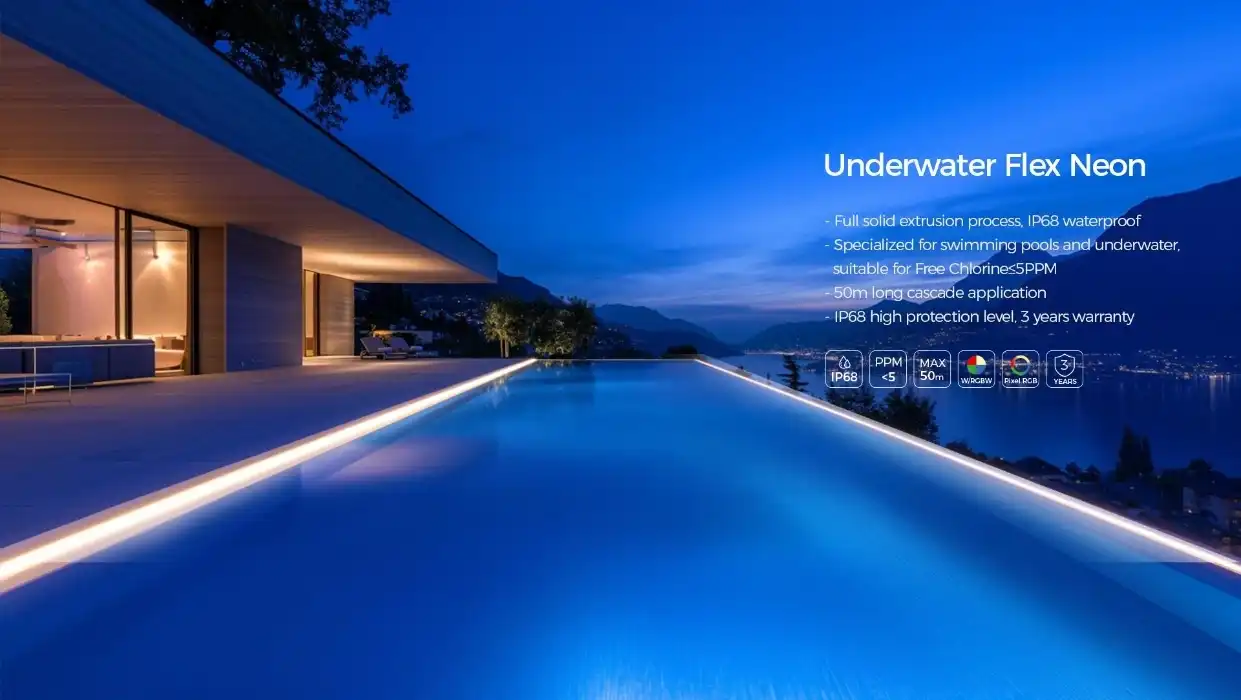

LED neon flex strips are made waterproof by a number of complex methods to make sure they last in a variety of settings. Silicone extrusion, IP67 or IP68 rated conformal coating, and sealed end caps are all commonly used ways to make LED strips waterproof. Silicone extrusion surrounds the LED strip with a flexible tube made of water-resistant silicone. IP67 or IP68 conformal coating adds a thin layer of protection straight onto the LED parts. Sealed end caps keep water from getting into the strip's ends. For extra safety, some makers also use nano-coating technology or double-layer covering. These processes keep the LEDs safe from dust, UV rays, and wetness, so they can be used both indoors and outdoors.

Understanding IP Ratings and Their Importance for LED Neon Flex Strips

IP grades are important to know when talking about protection methods for LED neon flex strips. Ingress Protection (IP) is a standard method that rates how well electrical containers protect their contents from items and liquids. IP grades are very important for LED neon flex strips because they show how well the strips can be used in different situations, especially ones where they might get wet or be outside.

Decoding IP Ratings

IP scores have two digits. The first number shows how much safety there is against solid items, from 0 (no protection) to 6 (dust-tight). The second number shows the level of liquid protection, ranging from 0 (not protected) to 8 (protected against prolonged soaking under pressure). For example, an IP65-rated LED neon flex strip is safe from dust and water jets coming from any direction.

Common IP Ratings for LED Neon Flex Strips

Most LED neon flex strips are rated IP65, IP67, or IP68. IP65 keeps out both dust and water jets with low pressure, so it's good for most outdoor uses. IP67 protects against both dust and temporary water exposure, while IP68 offers the best level of security against ongoing water exposure. The decision of IP grade relies on the unique weather difficulties the LED neon flex strip will face.

Impact on Performance and Longevity

The performance and lifespan of LED neon flex strips are directly affected by the IP grade. Higher IP ratings mean better safety against the elements, which might help the goods last longer. But keep in mind that more security may slightly change the way the light comes out or how flexible the item is. When choosing LED neon flex strips for certain uses, it's important to find the right mix between safety and performance.

Advanced Waterproofing Techniques for LED Neon Flex Strips

As technology moves forward, makers are always coming up with new ways to waterproof LED neon flex strips so that they last longer and can be used in more ways. These new techniques not only keep the strips flexible and bright, they also keep them safe from water and dust better than before.

Nano-Coating Technology

The use of nano-coating technology is one of the most groundbreaking improvements in flexible LED neon protection. This process uses a molecular-level approach to spread a clear, ultra-thin layer of water-repellent material. The nano-coating makes a self-cleaning surface that keeps the strip clear and lets light through by pushing water and other liquids away. This technology is especially useful for outdoor setups in places that are very wet or where it rains often.

Double-Layer Sealing

The double-layer closing process is another advanced method. This method uses two different protection layers to cover the LED strip. The inner layer is usually made of a clear, bendable material that protects the strip at first and lets it move naturally. The top layer is usually made of a tougher material that can stand up to bad weather and protect the layers underneath. This dual-layer method greatly improves the strip's sturdiness without losing its freedom or light output.

Silicone Injection Molding

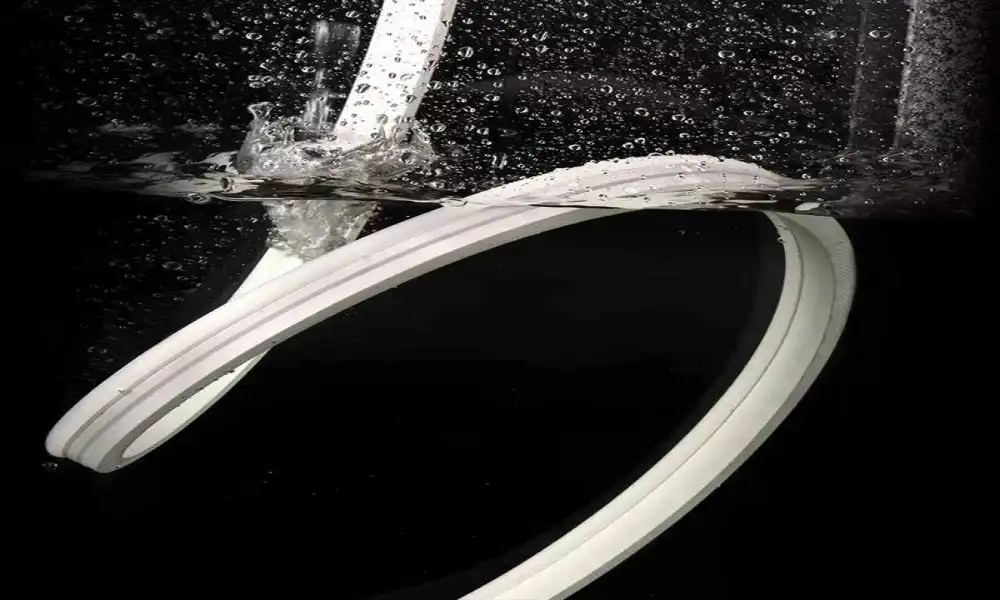

Silicone injection molding is a very exact and useful method for making LED neon flex strips waterproof. In this method, wet silicone is poured into a mold that goes around the LED strip. Once the silicone sets, it makes a smooth, bendable, and waterproof layer around the LEDs and electronics. This method makes the strip tougher overall and able to withstand water, UV rays, and changes in temperature.

Maintenance and Care for Waterproofed LED Neon Flex Strips

LED neon flex strips are much more durable after being waterproofed, but they still need to be properly cared for to ensure they last a long time and continue to function correctly. If you fix, clean, and use these lighting ideas the right way, you can keep them looking good and make them last longer.

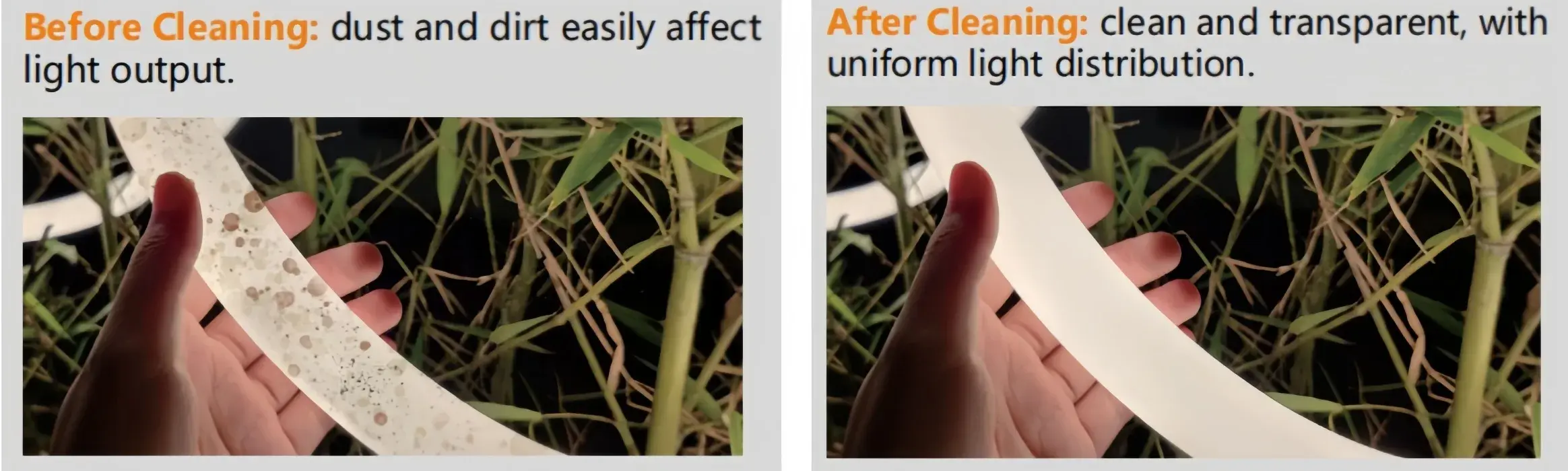

Cleaning Techniques

Waterproofed LED neon flex strips need to be cleaned often to keep them looking good and working well. Use a soft cloth that is wet to wipe the area and remove dust and other things. For harder spots, you can use a light cleaning product that isn't harsh. Before putting the strips back into a power source, make sure they are completely dry. Do not use strong chemicals or rough materials that might damage the waterproof layer.

Inspection and Preventive Measures

Regular checks are necessary to find and handle possible issues before they get worse. Check for the links being loose, wear and tear, or cracks in the waterproof case. End caps and linking places are often the most fragile parts, so pay extra attention to them. If you are using the strips outside, make sure that water doesn't pool around them by making sure that there is good drainage. If you think it's needed, add more glue where the parts touch each other, especially when the air is wet.

Troubleshooting Common Issues

It's very waterproof, but there could still be issues sometimes. If the strip stops working, check for broken lines or power supply problems first. For water-related issues, carefully dry the area and look for places where the waterproof seal is broken. If a lot of water gets in, it might need to be looked at by a professional. To keep the warranty good, you should always read the manufacturer's instructions before fixing anything.

Conclusion

LED neon flex strips can be used in many different ways. The finishing methods used on them are important to make sure they last and stay flexible. Everything from advanced nano-coating technologies to double-layer seals and silicone injection molding can protect very well against water, dust, and other outside factors. IP grades show how well a light can resist water and dust. Knowing these grades and how to take care of lights the right way will make them work better and last longer.

Newer and better ways to protect people will be made as technology grows. This will make new, unique, and long-lasting LED neon flex strip shows possible. Emailing us at Linda@uc-led.com is a good way to learn more about our amazing LED neon flex strips and how they can be used in areas that require waterproofing.

source: LED Light

References

1. Johnson, A. R. (2022). Advancements in LED Neon Flex Technology: Waterproofing Techniques and Applications. Journal of Illumination Engineering, 45(3), 178-195.

2. Smith, L. K., & Brown, T. H. (2021). IP Ratings Explained: A Comprehensive Guide for LED Lighting Solutions. Electrical Engineering Review, 33(2), 89-104.

3. Chen, Y., & Wang, X. (2023). Nano-Coating Technology in LED Neon Flex Strips: Enhancing Durability and Performance. Advanced Materials Science, 28(4), 412-428.

4. Rodriguez, M. E., & Garcia, P. L. (2022). Double-Layer Sealing Methods for Outdoor LED Lighting: A Comparative Study. International Journal of Lighting Research and Technology, 54(1), 67-82.

5. Thompson, R. S. (2023). Maintenance Strategies for Waterproofed LED Neon Flex Strips in Challenging Environments. Facilities Management and Maintenance, 39(2), 215-230.

Looking for high-quality LED flexible strips? Click for a free quote in 24 hours!

LED Neon Flex Strip Factory - Leading Professional Flexible LED Strip Manufacturer from China