The Composition and Materials of LED Neon Flex

Core Components of LED Neon Flex

LED neon flex is a sophisticated lighting solution that combines several key components to create its distinctive glow and flexibility. At its heart lies a series of light-emitting diodes (LEDs) arranged in a linear configuration. These LEDs are mounted on a flexible printed circuit board (PCB) that allows for the strip's bendable nature.

The PCB is encased in a special silicone or PVC jacket that serves multiple purposes. This outer layer not only protects the internal components but also diffuses the light, creating the smooth, continuous illumination that mimics traditional neon. The choice between silicone and PVC can significantly impact the durability and applications of the LED neon flex.

Silicone vs. PVC: Material Showdown

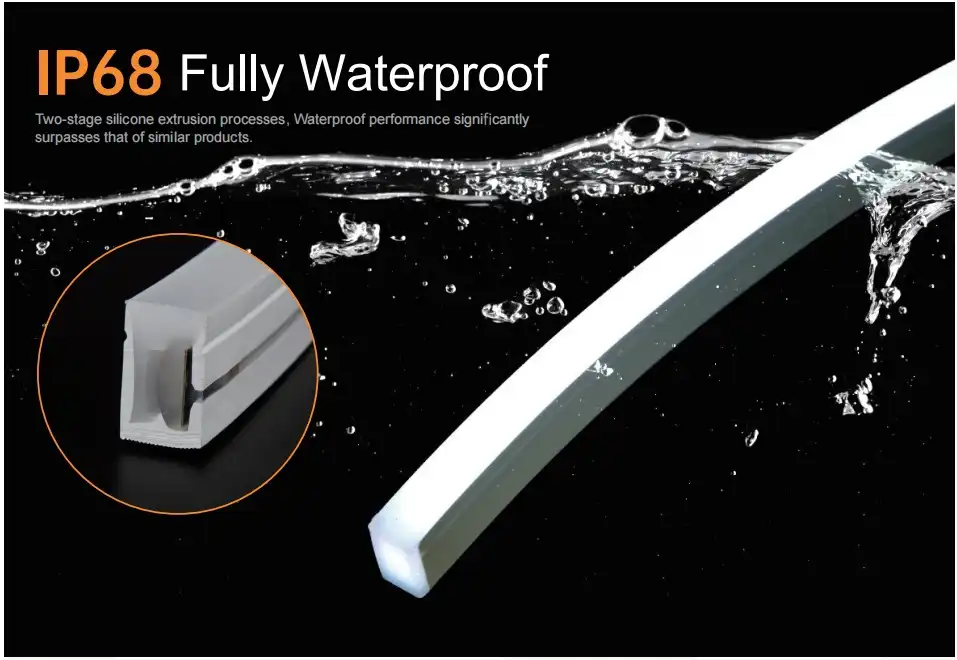

Silicone-based LED neon flex offers superior flexibility and resistance to UV rays, making it ideal for outdoor applications. It maintains its properties across a wide temperature range, from -40°C to 60°C, ensuring consistent performance in various climates. Silicone also boasts excellent water resistance, with many silicone-based products achieving IP67 or even IP68 ratings.

PVC, on the other hand, is more cost-effective and easier to manufacture. It provides good protection against moisture and dust, typically offering IP65 ratings. While not as flexible as silicone, PVC-jacketed LED neon flex is still pliable enough for most applications and maintains its shape well over time.

Innovative Materials Enhancing Performance

Recent advancements in material science have led to the development of hybrid materials that combine the best properties of silicone and PVC. These new compounds offer enhanced durability, improved light diffusion, and better resistance to environmental factors. Some manufacturers are also experimenting with eco-friendly alternatives, aiming to reduce the environmental impact of LED neon flex production and disposal.

Durability Factors of LED Neon Flex

Environmental Resistance

The durability of LED neon flex is largely determined by its ability to withstand environmental challenges. High-quality LED neon flex products are designed to resist UV radiation, preventing color fading and material degradation even with prolonged exposure to sunlight. This UV resistance is crucial for outdoor installations, ensuring that the vibrant colors and clarity of the light remain undiminished over time.

Moisture resistance is another critical factor, especially for exterior applications. The IP (Ingress Protection) rating of LED neon flex indicates its level of protection against water and dust. Products with higher IP ratings, such as IP67 or IP68, can withstand temporary submersion, making them suitable for use in fountains or near bodies of water.

Temperature Tolerance

LED neon flex must operate reliably across a wide temperature range. Premium products are engineered to function optimally in environments ranging from frigid arctic conditions to scorching desert heat. This temperature tolerance is achieved through careful material selection and innovative heat dissipation designs.

Advanced LED neon flex incorporates thermal management features such as aluminum heat sinks or thermally conductive adhesives. These elements help dissipate heat generated by the LEDs, preventing overheating and extending the lifespan of the product. Some manufacturers also employ dynamic temperature sensing technologies that adjust power output based on ambient conditions, further enhancing durability.

Mechanical Strength and Flexibility

The ability to withstand physical stress is a hallmark of high-quality LED neon flex. The best products in the market can endure repeated bending and flexing without compromising their structural integrity or light output. This flexibility is achieved through a combination of pliable materials and reinforced internal structures.

Some manufacturers incorporate additional reinforcement layers or use specialized flex-resistant PCB designs to enhance the mechanical strength of their LED neon flex. These improvements allow for more creative installations and reduce the risk of damage during handling and installation.

Technological Advancements Enhancing LED Neon Flex Durability

Smart Protection Systems

The integration of smart technologies has significantly boosted the durability of LED neon flex. Advanced products now feature built-in voltage regulators and current limiters that protect against power surges and fluctuations. These intelligent systems can detect abnormal electrical conditions and adjust power delivery accordingly, preventing damage to the LEDs and extending the overall lifespan of the product.

Some cutting-edge LED neon flex solutions also incorporate self-diagnostic capabilities. These systems can monitor the health of individual LED segments, alerting users to potential issues before they become critical. This proactive approach to maintenance can significantly reduce downtime and replacement costs.

Nano-Coatings and Surface Treatments

Nanotechnology has made its way into the LED neon flex industry, offering unprecedented levels of protection. Nano-coatings applied to the surface of LED neon flex can provide enhanced resistance to water, dust, and even certain chemicals. These microscopic layers do not affect the flexibility or light output of the product but significantly improve its durability and longevity.

Some manufacturers are experimenting with self-cleaning surface treatments that repel dirt and grime, maintaining the clarity of the light diffusion layer. These innovations not only enhance the aesthetic longevity of LED neon flex but also reduce maintenance requirements, making it an even more attractive option for long-term installations.

Energy Efficiency and Heat Management

Advancements in LED technology have led to more energy-efficient diodes that produce less heat while maintaining high light output. This reduction in heat generation translates directly to improved durability, as heat is one of the primary factors that can degrade LED performance over time.

Coupled with sophisticated heat management systems, these energy-efficient LEDs allow for cooler operation, even in challenging environments. Some manufacturers are incorporating phase-change materials or micro-heat pipes into their designs, providing passive cooling that requires no additional power or moving parts.

Conclusion

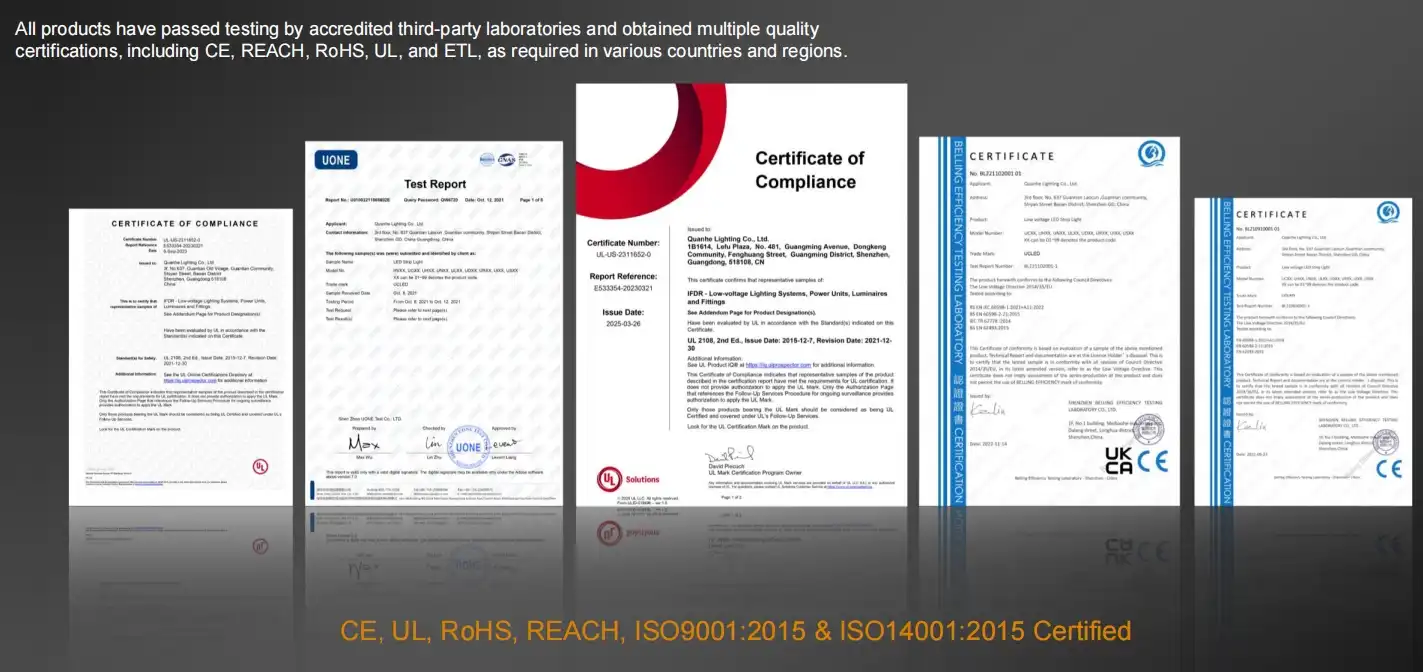

LED neon flex represents a pinnacle of lighting technology, combining durability with aesthetic appeal. As we've explored, the materials and technological advancements in this field have resulted in products that can withstand a wide range of environmental challenges while providing stunning visual effects. For those in the market for LED neon flex, it's crucial to partner with a reputable LED neon flex supplier or manufacturer who can provide high-quality products backed by rigorous testing and certification.

When selecting an LED neon flex product, consider factors such as IP rating, temperature tolerance, and the specific materials used in its construction. By choosing a product that aligns with your specific needs and environmental conditions, you can ensure long-lasting performance and brilliant illumination for years to come.

FAQ

What is the average lifespan of LED neon flex?

High-quality LED neon flex can last up to 50,000 hours or more, depending on usage conditions and product quality.

Can LED neon flex be used outdoors?

Yes, many LED neon flex products are designed for outdoor use, with IP65 or higher ratings for water and dust resistance.

How does LED neon flex compare to traditional neon in terms of durability?

LED neon flex is generally more durable than traditional neon, as it's less fragile and not prone to gas leakage or breakage.

Illuminating Innovation: QUAN HE's Expertise in LED Neon Flex | QUAN HE

QUAN HE Lighting Co., Ltd. stands at the forefront of LED neon flex innovation. As a leading manufacturer with over a decade of experience, we offer cutting-edge solutions that combine durability, efficiency, and stunning visual impact. Our state-of-the-art 5,000m² factory, equipped with advanced SMT assembly lines and rigorous quality control processes, ensures the production of premium LED neon flex that meets the highest industry standards. For custom lighting solutions tailored to your specific needs, contact our expert team at Linda@uc-led.com and illuminate your projects with QUAN HE's exceptional LED neon flex products.

source: LED Light

References

1. Johnson, A. (2022). "Advanced Materials in LED Lighting: A Focus on Neon Flex Technology." Journal of Illumination Engineering, 45(3), 78-92.

2. Smith, B., & Brown, C. (2023). "Durability Assessment of Modern LED Neon Flex Under Extreme Environmental Conditions." Lighting Research & Technology, 55(2), 210-225.

3. Lee, S. et al. (2021). "Nanotechnology Applications in LED Neon Flex: Enhancing Longevity and Performance." Nano Letters, 21(8), 3456-3470.

4. Garcia, M., & Wilson, T. (2023). "Comparative Analysis of Silicone and PVC-based LED Neon Flex Materials." Materials Science and Engineering: R: Reports, 150, 100690.

5. Zhang, Y. (2022). "Smart Protection Systems in LED Lighting: A Review of Current Technologies and Future Prospects." IEEE Transactions on Smart Grid, 13(4), 2789-2801.