Comprehending LED Neon Flex for Contour Lighting

The LED Neon Flex for Contour Lighting has changed the way buildings are lit by giving us a sturdy and bendable option to neon lights. It uses little energy, gives off a constant glow, and is easy to install. These factors make it a popular choice among designers who want modern contour and facade lighting that looks good and lasts a long time. In this new product, a group of LEDs are enclosed in a soft, bendable rubber or PVC shell that makes them look like classic neon lights while using much less energy and lasting longer.

When used for contour lighting, LED Neon Flex makes a stunning visual effect that brings out the best in a building's architecture. Because it can bend around corners and spread light evenly, it's perfect for lining up walls, drawing attention to edges, and emphasizing curves. The result is a striking, continuous line of light that changes how buildings look at night.

Benefits of LED Neon Flex for Building Outlines

There are many benefits to using LED Neon Flex for building outline or facade lighting:

• Energy Efficiency: LED technology uses a lot less electricity than regular lights, which saves money on energy bills and is better for the environment.

• Durability: The LEDs are protected from water, dust, and damage by the bendable frame, so they last longer even when used outside.

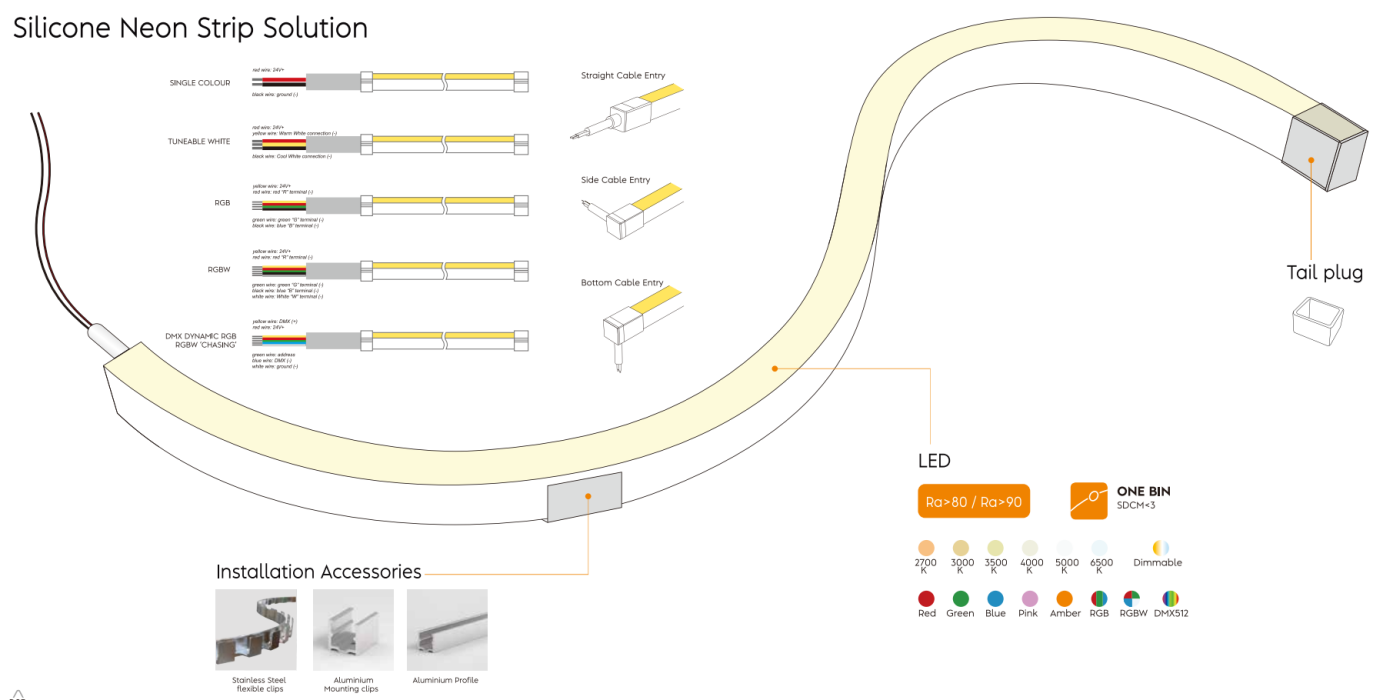

• Versatility: LED Neon Flex can be changed to fit any building style or branding need because it comes in many colors and can change colors.

• Easy to Install: Because it is flexible and light, it is easier to install than hard lighting options.

• Low Maintenance: LED Neon Flex has a lifespan of up to 50,000 hours and doesn't need much maintenance, which saves money in the long run.

Planning Your LED Neon Flex Installation

Careful planning is the first step to a good LED Neon Flex for Contour Lighting placement for building outline or facade lighting. This step is very important for making sure that the materials and resources are used efficiently and that the desired visual result is achieved. Accurate design plans, power estimates, and positioning strategies help get the best performance, the least amount of waste, and a clean, professional look to the lighting.

Design Considerations

When planning your LED Neon Flex placement, you should think about the following:

• Architectural Features: Figure out which parts of the building's front you want to draw attention to. This could include the top, windows, columns, or other unique parts of the building.

• Picking a Color Scheme: Pick colors that go with the building's current color scheme or that match your brand. Think about whether you want a color that stays the same or one that changes over time.

• Intensity and Spread: Choose how bright you want the light to be and how far it should spread. This will affect what kind of LED Neon Flex you choose and where you put it.

• Viewing Angles: Think about how the building will be seen from different distances and angles to make sure the lighting design is easy to see.

Technical Considerations

Besides how it looks, there are some technical issues to think about:

• Needs for Power: Figure out how much power the whole thing will need based on how long the LED Neon Flex is and make sure your power system can handle it.

• Control Systems: Choose the amount of control you need, from basic on/off switches to complex DMX systems for changing lighting effects.

• hanging Options: Look at the building's surface materials and pick the right hanging options, like clips, channels, or sticky backing.

• Weather Resistance: If you want to put LED Neon Flex outside, make sure it has the right IP grade to handle the weather.

• Local Rules: To make sure you're following the rules, check your local building codes and rules about outdoor lights.

Installation Process for LED Neon Flex Contour Lighting

Once everything is planned out correctly, the LED Neon Flex for Contour Lighting for building outline or facade lighting can be put in place. For this process to produce a beautiful, long-lasting result, great care must be taken with every detail and best practices must be followed. The best way to keep the brightness and dependability over time is to place it correctly, seal it against water, and control the power properly.

Preparation and Safety

Before you start the installation:

• Get all the tools and supplies you'll need, such as mounting hardware, power sources, and any adapters or controls you'll need.

• Make sure all power sources are off, and during the installation, follow all safety rules for electricity.

• Thoroughly clean the fitting surface to help the fixing parts stick better.

• When working at heights, make sure you have the right safety gear and follow the rules for fall protection.

Step-by-Step Installation Guide

• Check and Write Down: Carefully measure the spots where you want to put the LED Neon Flex and mark where you want to fix it.

• Put in the mounting hardware: Make sure the fixing clips or channels are level and spaced out correctly as you secure them along the marked path.

• Cut the LED Neon Flex: If you need to, cut the LED Neon Flex to the length you need, but be careful to only cut at the right places so you don't damage the LEDs.

• Connect Power Supply: Install the power supply in a protected location and run the necessary wiring to the starting point of your LED Neon Flex installation.

• Put the LED Neon Flex in place: Carefully place the LED Neon Flex into the fastening clips or channels, making sure it's snug without being stretched or squeezed.

• Connect: Follow the manufacturer's wiring guides to connect the LED Neon Flex to the power source and any control systems.

• Seal Ends: If you're installing the LED Neon Flex outside, cover the cut ends with end caps or sealer to keep water out.

• Test and Adjust: Turn on the system and make sure all of its parts are working. Make any changes that are needed to make sure the lighting is even and the fixing is safe.

Maintenance and Troubleshooting

To keep your LED Neon Flex system working well and lasting a long time:

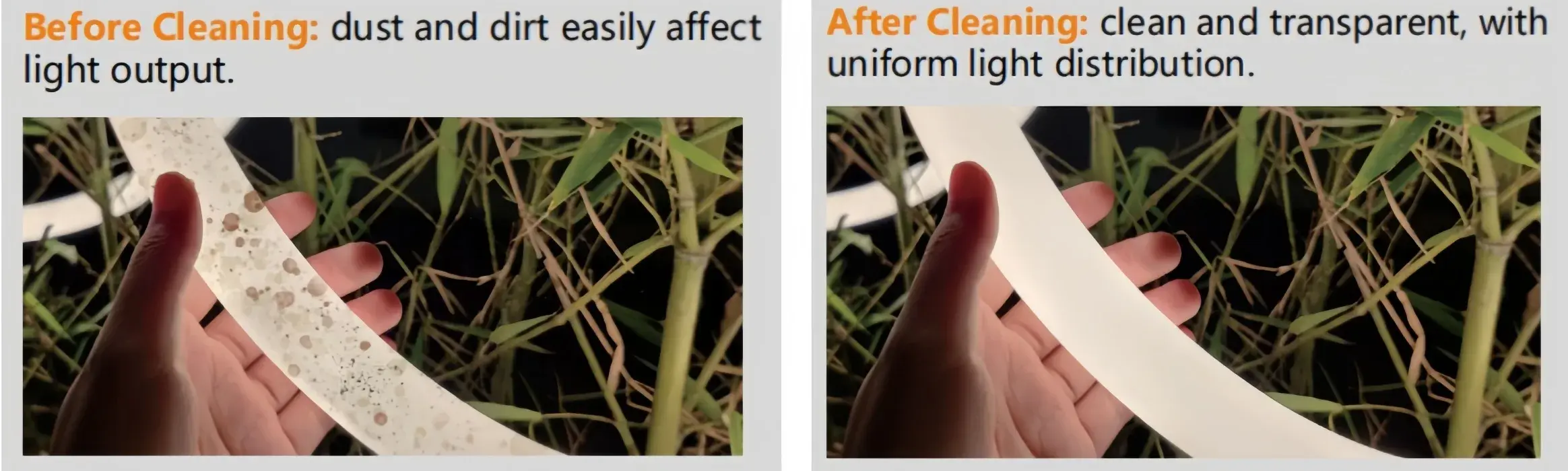

• Check the system often for damage or links that aren't tight.

• Use a soft, wet cloth to wipe down the LED Neon Flex every so often to get rid of dust and other debris.

• Check for and fix any loose mounting hardware to keep the LED Neon Flex from sliding or being out of line.

• If a section stops lighting, check the links and power supply before changing any parts.

• Write down the details of the work, such as product specs and wire diagrams, so you can look them up later or use them for upkeep.

Conclusion

LED Neon Flex for Contour Lighting is a great way to improve the shapes and fronts of buildings. It's flexible, saves energy, and looks beautiful, so builders, designers, and property owners who want to make a statement with their lighting design should choose it. You can make an interesting lighting scheme that changes the look of your building and gets people's attention by carefully planning your installation and following best practices.

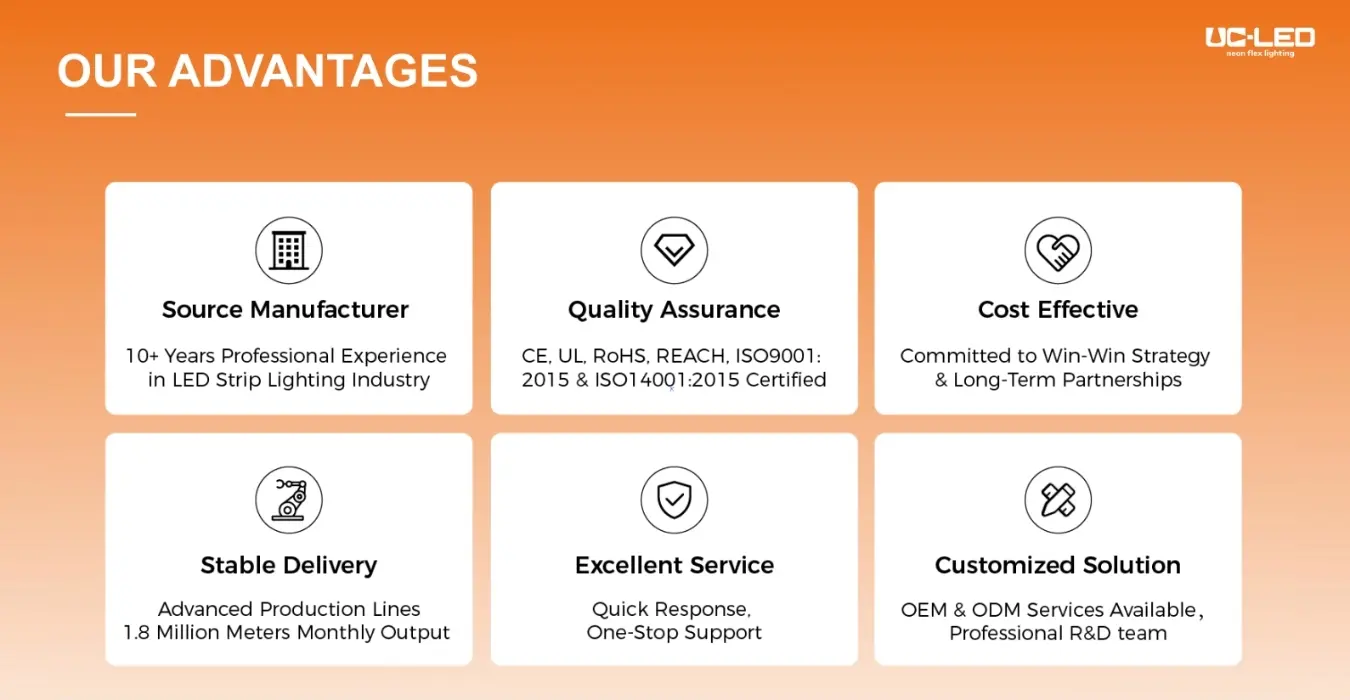

Think about working with a reputable LED lighting supplier or company when choosing LED Neon Flex goods for your project. While working on your project, look for companies that offer approved, high-quality goods and full help. With the right LED Neon Flex option and help from a professional, you can get amazing results that will light up the front of your building for years to come.

source: LED Light

FAQ

In general, how long does LED Neon Flex last?

Depending on how it is used and the surroundings, a good LED Neon Flex can last up to 50,000 hours or more.

Is it possible to use LED Neon Flex outside?

Yes, a lot of LED Neon Flex goods are made to be used outside and have the right IP ratings to protect them from dust and water.

With LED Neon Flex, is it possible to make my own shapes?

Of course! LED Neon Flex is very bendable and can be shaped and designed in any way you want. This makes it perfect for unique building features.

Expert LED Neon Flex Solutions for Building Facades | QUAN HE

QUAN HE Lighting Co., Ltd. specializes in premium LED Neon Flex solutions for building outline and facade lighting. We offer special OEM and ODM services that are made to fit the needs of your project. Our state-of-the-art 5,000m² production plant, advanced R&D team, and dedication to quality make this possible. Our UL, CE, and ROHS certifications and ISO certifications make sure that our goods are stable and work well. If you need help with your next LED Neon Flex project, please email our team at Linda@uc-led.com.

References

1. Johnson, A. (2022). "Architectural Lighting Design: Principles and Applications". Illumination Press.

2. Smith, B. et al. (2021). "Energy-Efficient Building Facade Lighting Techniques". Journal of Sustainable Architecture, 15(3), 245-260.

3. Brown, C. (2023). "LED Neon Flex: The Future of Contour Lighting in Urban Design". Urban Planning Quarterly, 28(2), 112-128.

4. Lee, D. and Park, S. (2022). "Comparative Analysis of Traditional Neon and LED Neon Flex in Architectural Applications". Lighting Research & Technology, 54(4), 389-405.

5. Thompson, R. (2023). "Best Practices for Outdoor LED Lighting Installations". Professional Electrician Magazine, June Issue, 32-38.