Understanding the Core Components of LED Neon Flex

The Heart of Illumination: LED Chips

At the core of every LED neon flex strip lies its LED chips. These miniature light sources are the primary determinants of the strip's brightness, color accuracy, and energy efficiency. High-performance LED neon flex typically utilizes top-tier LED chips from renowned manufacturers. These chips boast superior luminous efficacy, measured in lumens per watt, ensuring optimal light output while minimizing energy consumption.

The quality of LED chips also influences color consistency and the ability to produce vivid, saturated hues. Premium LED neon flex often incorporates chips with tight binning processes, resulting in minimal color variation along the strip's length. This consistency is crucial for achieving a uniform, professional appearance in architectural lighting and signage applications.

Flexibility and Durability: The Silicone Casing

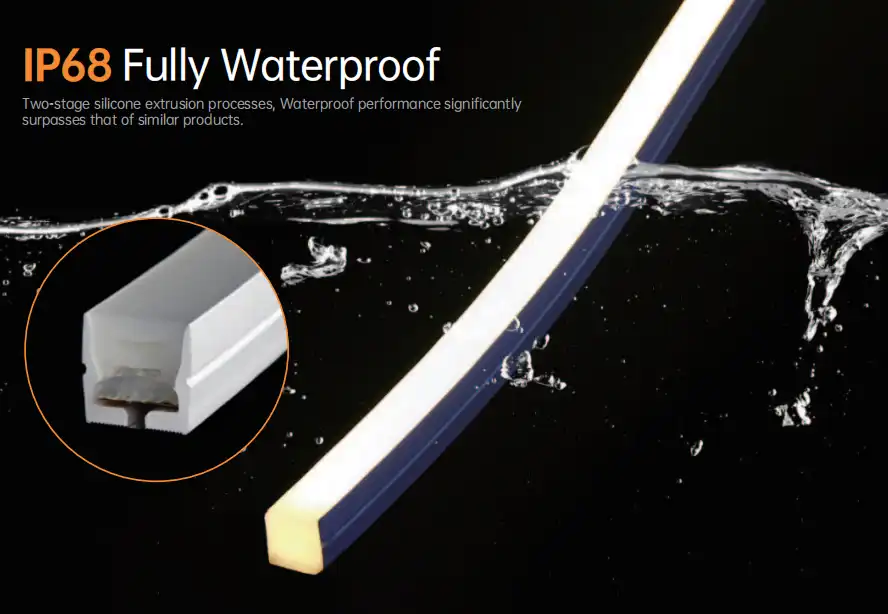

The silicone casing surrounding the LED chips plays a pivotal role in the neon flex's performance and longevity. High-quality LED neon flex features a seamless, UV-resistant silicone jacket that offers excellent flexibility without compromising light diffusion. This casing should be thick enough to protect the internal components while remaining pliable for easy installation and shaping.

Superior silicone casings also contribute to the product's weather resistance and durability. Look for LED neon flex with high IP (Ingress Protection) ratings, such as IP65 or IP67, which indicate excellent protection against dust and water ingress. This level of protection is essential for outdoor applications or installations in challenging environments.

Power Distribution: PCB Design and Conductors

The printed circuit board (PCB) and conductors within LED neon flex are critical for ensuring consistent power distribution and heat management. High-performance products often feature copper PCBs with optimized trace designs, facilitating efficient power delivery to each LED chip. This results in uniform brightness along the entire length of the strip, even in longer runs.

Quality conductors, typically made of tinned copper, should be adequately sized to handle the current requirements without voltage drop. This is particularly important for maintaining color consistency in RGB or RGBW LED neon flex strips, where precise voltage control is necessary for accurate color mixing.

Evaluating Performance Metrics and Specifications

Luminous Efficacy and Output

When assessing LED neon flex performance, luminous efficacy is a key metric to consider. This measure, expressed in lumens per watt (lm/W), indicates how efficiently the product converts electrical power into visible light. High-performance LED neon flex typically boasts efficacy ratings of 100 lm/W or higher, signifying excellent energy efficiency.

Equally important is the overall luminous output, measured in lumens per meter or foot. This specification gives insight into the brightness of the neon flex. However, it's crucial to consider that raw lumen output doesn't always translate to perceived brightness, especially in products designed for direct view applications like signage.

Color Rendering and Consistency

For applications where color accuracy is paramount, such as retail displays or architectural lighting, the Color Rendering Index (CRI) becomes a critical specification. High-performance LED neon flex often features CRI values of 80 or above, with premium products reaching 90+. This ensures that illuminated objects appear natural and vibrant under the light.

Color consistency, measured by MacAdam ellipses or SDCM (Standard Deviation of Color Matching), is another vital factor. Look for products with tight color binning, ideally within 3-step MacAdam ellipses or lower, to ensure uniform color appearance along the entire length of the neon flex.

Beam Angle and Light Distribution

The beam angle of LED neon flex determines how the light is distributed. While traditional neon tubes emit light in a 360-degree pattern, LED neon flex typically has a more focused beam. High-performance products often offer beam angles between 120 to 180 degrees, providing a good balance between focused illumination and wider light spread.

Some manufacturers offer LED neon flex with specialized optics or light-guiding elements within the silicone casing. These features can help achieve more uniform light distribution or create specific lighting effects, enhancing the product's versatility in various applications.

Assessing Long-Term Reliability and Support

Lifespan and Lumen Maintenance

The longevity of LED neon flex is a crucial factor in its overall performance and value. High-quality products typically boast lifespans of 50,000 hours or more under normal operating conditions. However, it's essential to look beyond just the rated lifespan and consider the product's lumen maintenance characteristics.

Lumen maintenance, often expressed as L70 or L90 values, indicates how well the LED neon flex retains its initial brightness over time. Superior products maintain at least 70% of their initial output (L70) after 50,000 hours of operation. Some premium offerings even achieve L90 ratings, retaining 90% of their brightness over the same period, ensuring long-lasting, consistent illumination.

Thermal Management and Operating Temperature Range

Effective thermal management is crucial for the long-term performance and reliability of LED neon flex. High-quality products incorporate advanced heat dissipation techniques within their design, such as thermally conductive PCBs or specialized heat-spreading components. These features help maintain optimal operating temperatures, prolonging the life of the LEDs and preventing color shift over time.

Consider the specified operating temperature range when evaluating LED neon flex. Premium products often offer wider temperature tolerances, typically ranging from -20°C to 50°C or beyond. This broad range ensures reliable performance in varied environmental conditions, making the product suitable for both indoor and outdoor applications.

Warranty and Manufacturer Support

The warranty offered by the manufacturer is often a good indicator of the product's expected performance and the company's confidence in its reliability. High-performance LED neon flex typically comes with extended warranties, ranging from 3 to 5 years or even longer for premium lines. These warranties should cover not just defects in materials and workmanship but also performance aspects like lumen maintenance.

Beyond the warranty, assess the level of technical support and documentation provided by the manufacturer. Reputable companies offer comprehensive product datasheets, installation guides, and readily available technical assistance. Some may even provide custom design services or project-specific support, which can be invaluable for complex lighting installations.

Conclusion

Spotting high-performance LED neon flex requires a comprehensive evaluation of its components, specifications, and long-term reliability factors. By carefully considering aspects such as LED chip quality, silicone casing durability, power distribution efficiency, and key performance metrics like luminous efficacy and color consistency, you can identify products that will deliver superior results in your lighting projects. Remember to also factor in the manufacturer's reputation, warranty offerings, and support services when making your selection.

For more information on high-performance LED neon flex solutions tailored to your specific needs, don't hesitate to reach out to industry experts. Contact Linda@uc-led.com for personalized guidance and cutting-edge lighting solutions that elevate your projects to new heights of brilliance and efficiency.