Understanding LED Neon Flex Technology and Its Applications

LED neon flex is a flexible and energy-saving lighting option that has changed the way that people light spaces. This tube-shaped, bendable product looks like a regular neon light. It is more durable, uses less energy, and can be used in more designs than traditional neon lights. LED neon flex is made up of a lot of LED chips that are housed in flexible PVC or rubber. This makes a consistent light source that can be shaped and bent to fit different needs.

LED neon flex is much better than it used to be in terms of color rendering, light, and general performance. Today’s goods come in many colors, including RGB and RGBW versions that can make colors change in real time. Because it can be used in so many different ways, LED neon flex has become a popular lighting option for indoors and outdoors. Some examples are:

• Architectural accent lighting

• Signage and advertising displays

• Decorative lighting in hospitality and retail environments

• Landscape and facade lighting

• Event and stage lighting

As demand for LED neon flex rises, it's important to choose a provider who can supply high-quality goods that meet the needs of your projects. Let's look at the most important things to keep in mind when choosing a trustworthy LED neon flex provider.

Evaluating Manufacturing Capabilities and Product Quality

State-of-the-Art Production Facilities

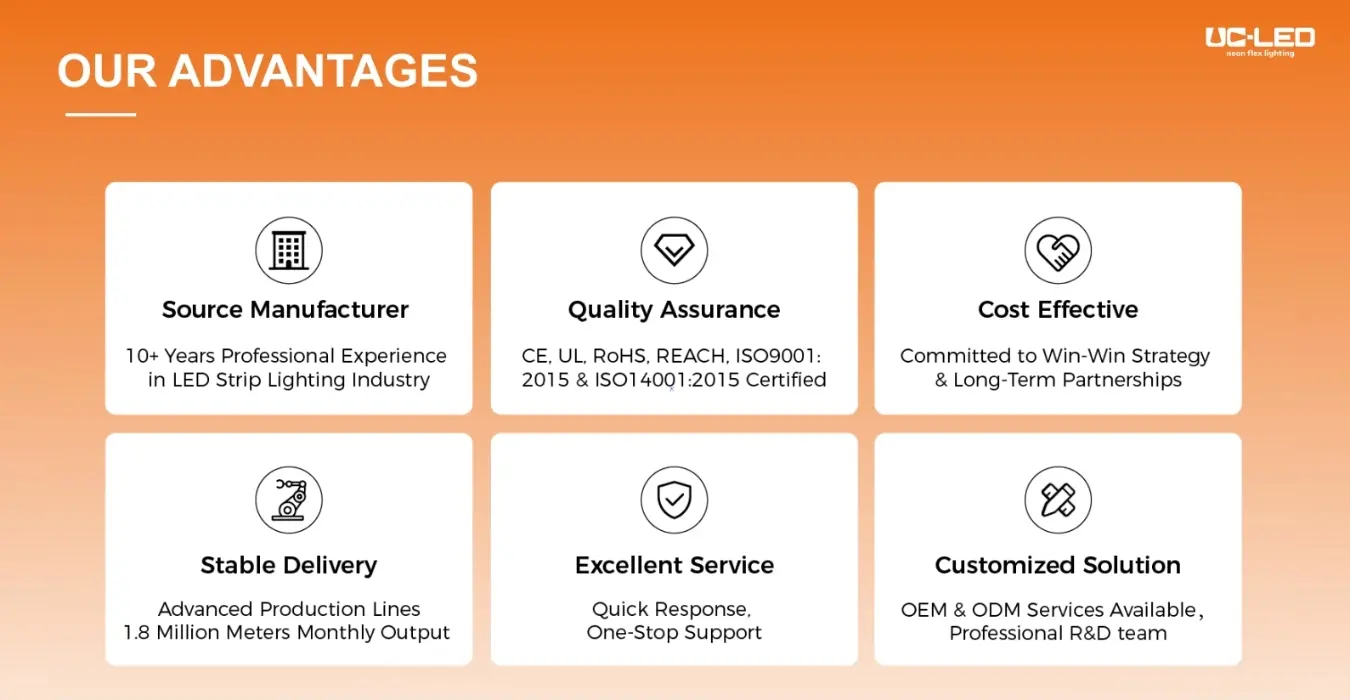

When picking an LED neon flex provider, it's important to think about how they make their products. A trustworthy provider should have a factory that uses modern technology and machines to make their products. This makes sure that the standard stays the same and that there is enough production capacity for big events. Suppliers who invest in automatic production lines and keep ISO-certified manufacturing facilities should be sought after because these factors help make products more reliable and of better quality.

Quality Control Measures

Throughout their production cycle, Reliable LED Neon Flex uses stringent quality control procedures. This includes checking the raw ingredients, the work that's been done so far, and the end products. Ask possible providers how they make sure their LED neon flex goods are good, and if they do color consistency checks, stress tests, and protection evaluations.

Product Specifications and Performance

Examine the technical specifications of the LED neon flex products offered by potential suppliers. Pay attention to factors such as:

• Luminous efficacy (lumens per watt)

• Color rendering index (CRI)

• IP rating for water and dust resistance

• Beam angle and light distribution

• Lifespan and warranty

A trustworthy seller should be able to give you full product datasheets and be open about how their goods work.

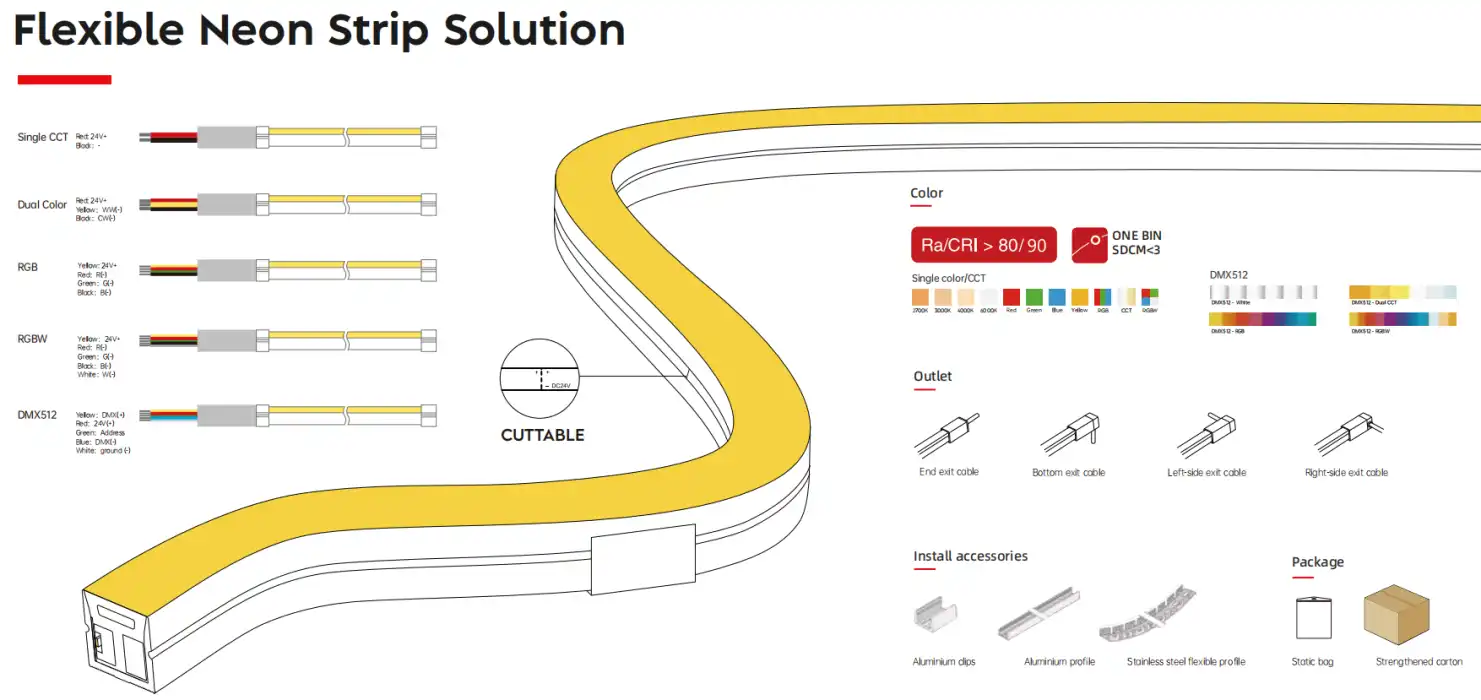

Assessing Customization Options and Technical Support

Flexibility in Design and Production

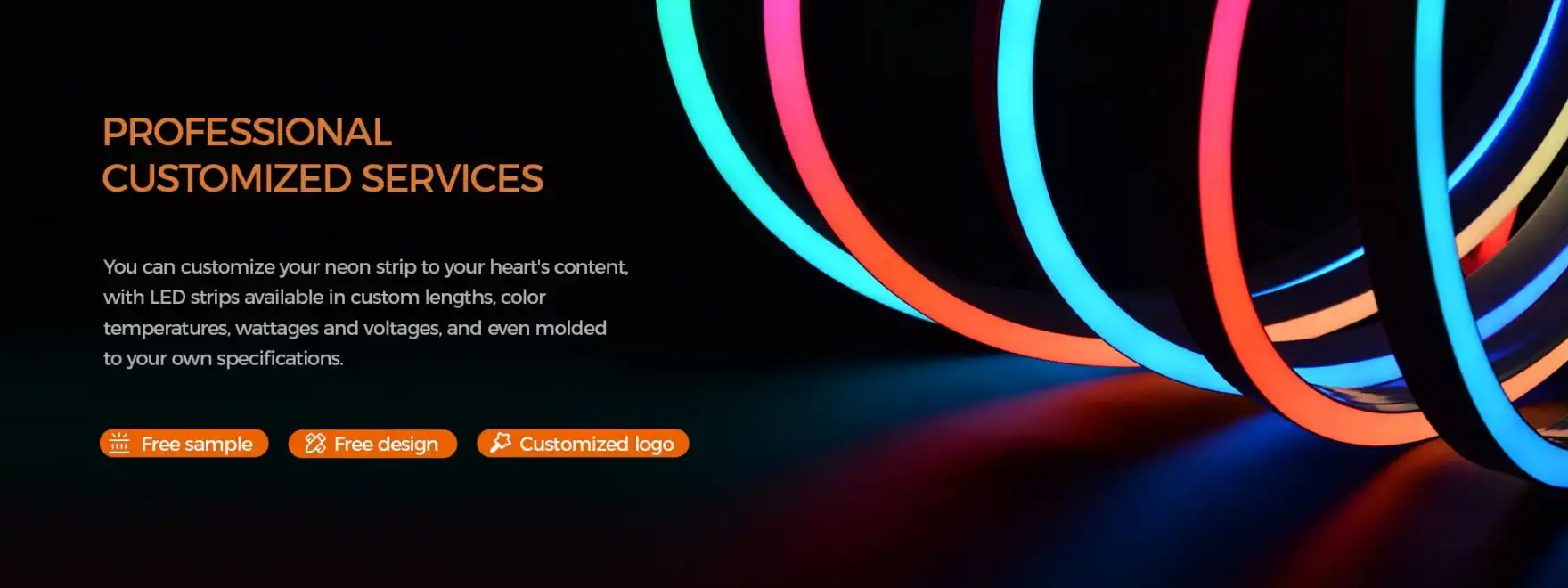

A good provider can offer custom-made LED neon flex options. Find makers who offer:

• Custom lengths and shapes

• Personalized color choices

• Customized lighting settings

• Unique plugs and ways to mount them

A provider with strong OEM and ODM skills can work with you to make LED neon flex goods that are exactly what you need for your project.

Technical Expertise and Support

Pick a provider whose research and development team keeps up with the newest LED technologies. This makes sure you can use the newest LED neon flex options and inventive features. Also, trustworthy vendors provide full technical help, which covers:

• Helping with design and suggesting products

• Help with installation and fixing problems

• Support after purchase and care tips

A skilled support team can be very helpful in getting the most out of your LED neon flex setups and making them last as long as possible.

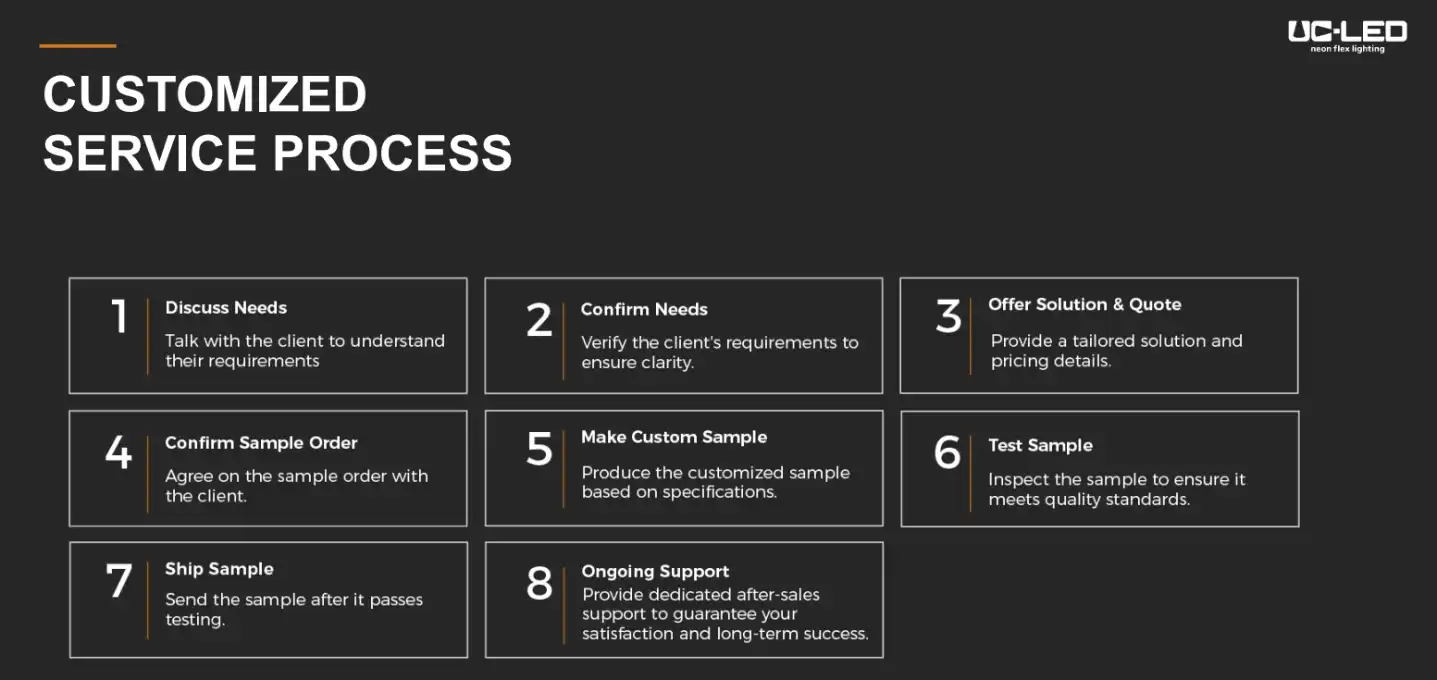

Sample Availability and Prototyping

Before placing a big order, it's important to test LED neon flex items to see how well they work and how good they are. Trustworthy providers should be able to give you samples or make mockups of unique designs. This lets you look at things like how much light is produced, how accurate the colors are, and how well it's built before you make up your mind about the details of your project.

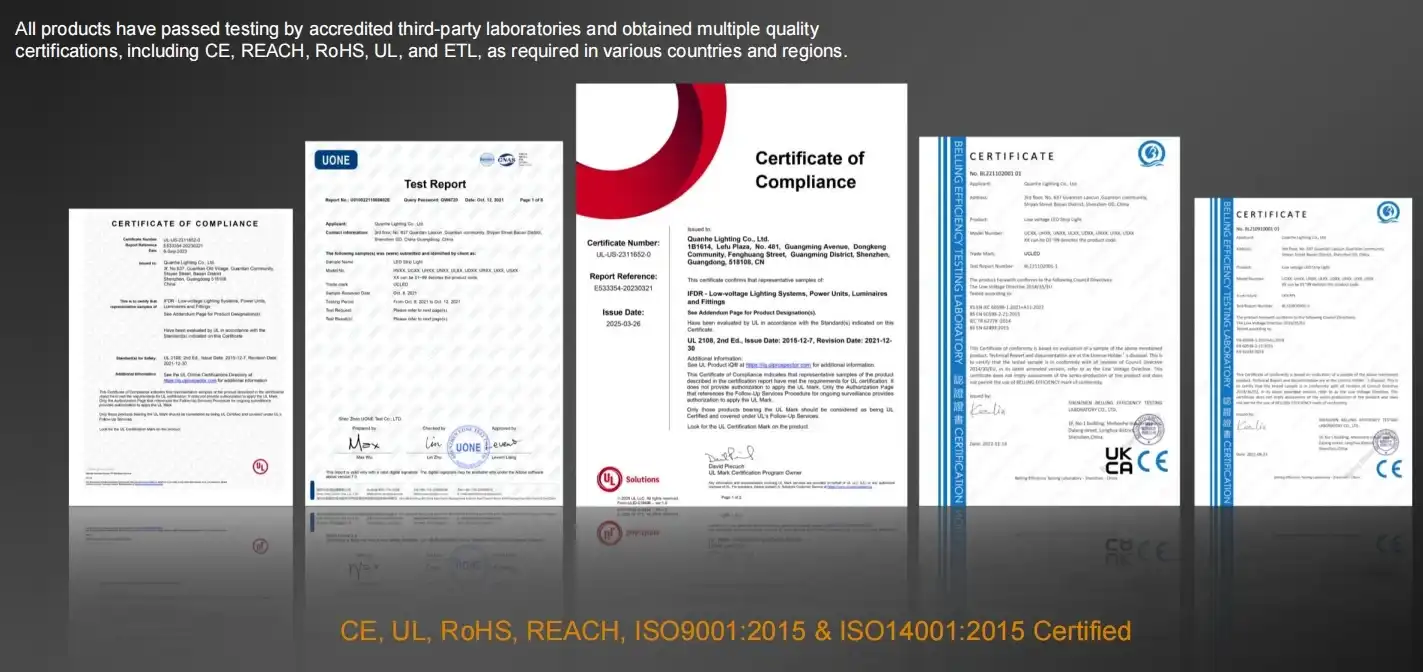

Verifying Certifications and Compliance Standards

Industry-Recognized Certifications

Make sure that the LED neon flex provider you choose has the right licenses to show that they are committed to safety and quality. For example, these certifications may be important:

• ISO 9001:2015 for quality management systems

• ISO 14001 for environmental management

• UL (Underwriters Laboratories) for product safety

• CE marking to show that the product meets European health, safety, and environmental standards

• RoHS for the restriction of hazardous substances.

These certificates show that the company follows strict rules and quality control steps.

Compliance with International Standards

LED neon flex goods should follow the rules for LED lighting items around the world. This includes following:

• IEC safety and performance standards

• Energy Star guidelines for energy saving.

• EMC standards (Electromagnetic Compatibility)

LED neon flex providers and other trustworthy vendors keep an eye on these standards and make sure their goods meet or go beyond the requirements.

Environmental Considerations

As sustainability becomes more important in the lighting business, look for providers who use and make eco-friendly products and methods. Find LED neon flex items that are:

• Good at using energy and have high lumens-per-watt rates.

• Does not contain dangerous things like lead and mercury

• Can be remade or is made from recovered materials

• Made to last a long time to keep waste down

LED neon flex options are more likely to be eco-friendly when they come from suppliers who show they care about the environment.

Conclusion

Choosing a good LED neon flex provider is an important choice that can have a big effect on how well your lighting projects turn out. If you take the time to consider a manufacturer's technical support, customization options, licenses, product quality, and production capabilities, you can find a provider who will deliver amazing LED neon flex goods made just for you. Remember to put providers who show they care about quality, innovation, and customer happiness first. This will make sure your lighting solutions last and meet the greatest standards in the field.

Frequently Asked Questions

How long does LED neon flex usually last?

Depending on how and where it's used, high-quality LED neon flex can last over 50,000 hours.

Is it possible to use LED neon flex outside?

Yes, a lot of LED neon flex goods are made to be used outside and have IP65 grades or higher for water and dust protection.

How does LED neon flex's energy efficiency compare to that of regular neon?

LED neon flex uses up to 80% less energy than regular neon lights, making it much more energy-efficient.

Can you get LED neon flex in unique shapes?

Yes, trusted companies offer customization services to make LED neon flex in different forms and shapes.

Which safety signs should I look for in LED neon flex items?

To be safe and follow global rules, you should check for UL, CE, and RoHS approvals.

Choose QUAN HE for Premium LED Neon Flex Solutions | QUAN HE

QUAN HE Lighting Co., Ltd. is a top producer and seller of LED neon flex, providing high-quality goods and a wide range of customization options. We offer new lighting options customized to meet your needs with our modern 5,000m² plant, ISO certifications, and professional R&D team. Try out QUAN HE's LED neon flex technology and see the difference for yourself. Emailing Linda@uc-led.com will get your projects lit up with accuracy and greatness.

References

1.Johnson, M. (2022). "The Evolution of LED Neon Flex Technology in Modern Lighting Design." Illumination Engineering Society Journal, 45(3), 78-92.

2.Smith, A. & Brown, R. (2023). "Selecting High-Quality LED Neon Flex: A Comprehensive Guide for Lighting Professionals." LED Professional Review, 18(2), 34-49.

3.Chen, L. et al. (2021). "Advancements in LED Neon Flex Manufacturing: Improving Durability and Performance." Journal of Solid State Lighting, 8(4), 112-128.

4.Williams, K. (2023). "Energy Efficiency and Sustainability in LED Neon Flex Production." Green Technology & Environmental Science News, 12(1), 55-67.

5.Thompson, E. & Davis, G. (2022). "Quality Control Measures in LED Neon Flex Manufacturing: Best Practices and Industry Standards." International Journal of Lighting Research and Technology, 54(6), 789-805.