Introducing 360° LED Neon Flex: A Versatile Lighting Solution

360° LED Neon Flex is a huge new step forward in both artistic and useful lighting. This new product gives you a smooth, unbroken glow that lights up the area from every angle, making it a great choice for all sorts of situations. LED neon flex is energy-saving, long-lasting, and very customizable, unlike regular neon lights.

Key Features of 360° LED Neon Flex

360 Degree LED Neon Flex can shine light evenly across its whole surface, which makes it unique. This lighting from all directions gets rid of dark spots and makes a beautiful effect that looks like old-fashioned glass neon tubes. Because they are made of rubber or PVC, which are bendable materials, these LED strips can be shaped and bent to fit different shapes and areas.

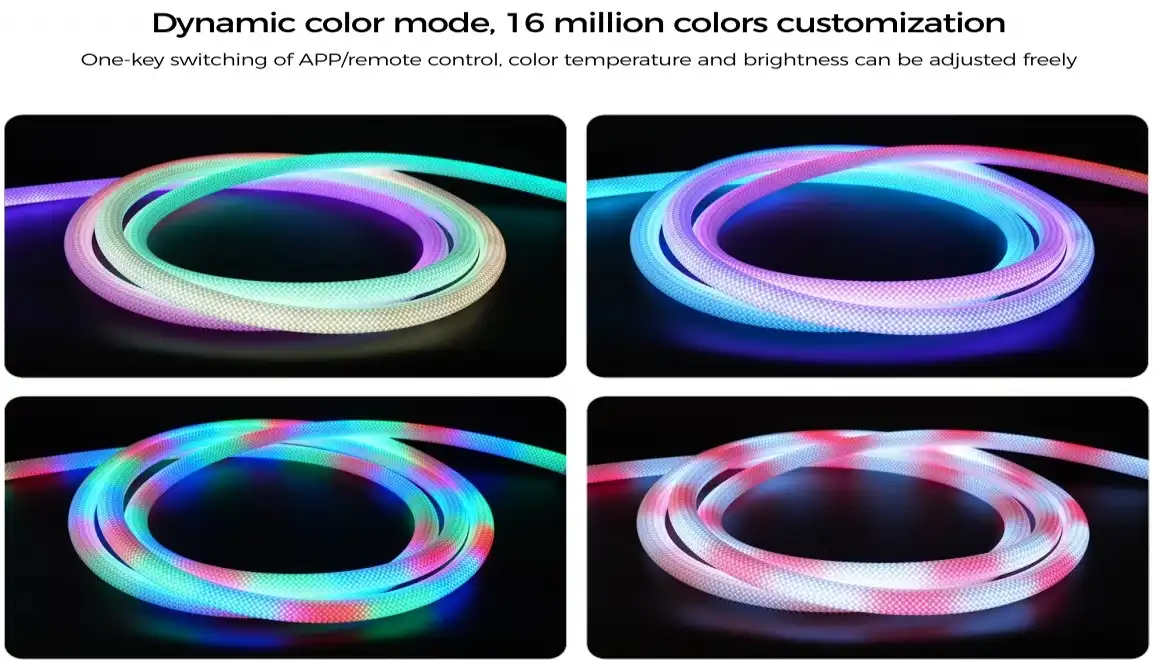

Today's 360° LED Neon Flex has a lot of great color choices, including RGB versions that let you change colors in a dynamic way. A lot of types have IP67 grades or higher, which means they can handle being around dust and water and can be used both indoors and outdoors.

Applications and Benefits

360 Degree LED Neon Flex is a very popular choice for many uses because it is so versatile:

- Lighting for architecture

- Signs and writing

- Decorations for events and stages

- Retail displays

- Lighting for landscapes

- Places for hospitality and entertainment

360° LED Neon Flex looks good, but that's not the only reason to use it. These lighting options use much less energy than standard LED lights. Plus, they live longer, need less upkeep, and are cooler, which makes them safer to use and handle.

Preparation for Mounting or Suspending 360° LED Neon Flex

Before you put your 360 Degree LED Neon Flex, you need to make sure you have everything you need. This planning part includes a few important steps that will make sure the installation goes well.

Assessing the Installation Area

Start by carefully checking out the area where you want to place or hang your LED neon wire. Think about these things:

- The stuff on the surface: What kind of material is it—wood, concrete, metal, or something else?

- Environmental conditions: Will the installation have to deal with moisture, very high or low temperatures, or direct sunlight?

- Power source proximity: Make sure that power sources and plugs are easy to get to.

- Visibility and effect: Figure out the best place to get the most visual impact.

To figure out how long a length of 360° LED Neon Flex you need, make sure to measure the fitting area carefully. It's a good idea to add a little extra length to make sure you have enough for any curves or changes that might happen during installation.

Gathering Necessary Tools and Materials

To make sure the work goes well, get all the tools and materials you need ahead of time. Common things you might need are:

- Mounting clips or channels that are made for 360° LED Neon Flex

- Screws, nails, or glue that will work on the surface you're mounting to

- A drill and the right drill bits (if you're mounting on hard surfaces)

- Wire cutters and strippers (if you want to make custom lengths or connections)

- A measuring tape and level

- A pencil or chalk for marking

- Safety gear like safety glasses and gloves

- Silicone sealant for setups outside

- Things to manage cables or wires

For systems that are suspended, you might also need:

- Suspension kits or special parts

- Strong wire or cord to hang from

- Ceiling hooks or bolts

Planning the Layout

Before beginning the physical installation, it's crucial to plan your layout meticulously. In this step, you Make a thorough drawing of your ideal layout for the 360° LED Neon Flex.

- Point marking for mounting: With chalk or a pencil, mark where the clips or support points will go.

- Taking the need for power into account: Figure out where the power sources, dimmers, and controls will go.

- Taking into account curves and bends Make sure your design follows the LED neon flex's minimum bend radius so it doesn't get broken.

A good installation that shows off everything your 360 Degree LED Neon Flex can do is only possible if you plan and prepare ahead of time. This careful preparation lowers the risk of making mistakes and guarantees a clean, professional outcome.

Step-by-Step Guide to Mounting and Suspending 360° LED Neon Flex

Now that all of the right steps have been taken, you can start to install it. This guide will show you how to both fix and hang your 360 Degree LED Neon Flex. This will make sure that it looks good and stays in place.

Mounting 360° LED Neon Flex

Surface Preparation: Remove all dust, grease, and other dirt from the fixing area. For things that are outdoors, make sure the surface is dry.

Clip Installation:

- Start to install the fixing clips using the points you marked ahead of time as a help.

- For hard surfaces, make test holes if you need to, and then use the right screws to hold the clips in place.

- You might be able to use clips with sticky backs on softer surfaces. Make sure the glue is rated for the weight and the elements of the area.

- Space the clips evenly apart, usually every 30–50 cm or as the maker says.

Neon Flex Installation:

- Press the 360 Degree LED Neon Flex into the fixed clips, starting at one end and being careful.

- As you go along the installation path, make sure that the neon flex is firmly set in each clip.

- For corners or curves, be careful to stay above the minimum bend radius so you don't hurt the LEDs or other parts inside.

Securing Ends and Connections:

- Use a sharp blade at the marked cutting places to cut the neon flex to length, then seal the end with the given end caps.

- Connect the neon flex to its power source or driver. Make sure that all of the connections are safe and protected from the weather if needed.

Suspending 360° LED Neon Flex

Anchor Point Installation:

- Mark your suspension points on the ceiling or supporting structure.

- Install strong hooks, eyebolts, or other suitable anchors at these places.

- Make sure that each pin is safely attached and can hold the weight of the bright flex.

Setting Up the Suspension System:

- Attach the suspension system you want (for example, wire, cable, or unique brackets) to the support points.

- If you are using wire or cord, make sure it is tight so it doesn't slide.

- For unique frames, be sure to check that they are level and properly lined up.

Neon Flex Attachment:

- Carefully add the 360° LED Neon Flex to your suspension system.

- If you use clips, make sure they are all spaced out evenly along the length of the neon flex.

- For special brackets, follow the manufacturer's instructions for how to connect them securely.

Leveling and Adjustments:

- Use a level to make sure your hanging neon flex is straight and smooth.

- Change the suspension system in any way that you need to in order to get the look you want.

Power Connection:

- Make sure that all of the wires are out of the way of the visual effect and connect the neon flex to its power source.

- Use cable ties or other wire management tools to keep the power lines neat and out of the way.

Final Checks and Considerations

After installing, do these last checks:

- Make sure all parts of the 360° LED Neon Flex are lighting up the right way.

- Make sure all of the links and mountings are tight.

- For things that will be outside, put silicone glue on any joints or end caps that are not covered up to make them more waterproof.

- Make sure that any buttons or dimmers are working well and easy to get to.

If you follow these steps, you can get a professional-looking display that shows off everything your 360° LED Neon Flex can do. If you aren't sure about any part of the construction process, keep safety in mind and call a professional plumber.

Conclusion

When you learn how to hang or hold 360 Degree LED Neon Flex, you can do a lot of unique things with lights. Thanks to its even glow and fadaptable nature, this handy product can change places and make designs come to life in ways that aren't possible with standard lighting. Following these instructions for installing your 360° LED Neon Flex will help make it as eye-catching as possible.

When you choose a 360° LED Neon Flex supplier or maker, think about things like the quality of the products, how much you can customize them, and the help they offer with technical issues. Find sellers who can do a lot of things, like help with planning and support after the sale. A good maker will give you full information about their products, installation tips, and maybe even custom solutions that are just right for your project.

Remember that the most beautiful 360° LED Neon Flex installation depends not only on the product, but also on the careful planning, exact execution, and close attention to detail during the mounting or hanging stage. If you make sure your 360° LED Neon Flex is installed correctly, it will stay bright for a long time, whether you're lighting up a business, making a sign that gets noticed, or setting the mood in a home.

Frequently Asked Questions

How long can a single power source light up 360° LED Neon Flex?

The longest length varies with the object and power sources. It usually falls somewhere between 10 and 50 meters. For correct information, always look at the manufacturer's specs.

Can you cut 360° LED Neon Flex to any length?

Yes, most 360° LED Neon Flex can be cut at certain places, which are usually written on the object. But, make sure to always cover the cut end with an end cap to keep it waterproof.

Can you use 360° LED Neon Flex outside?

A lot of 360° LED Neon Flex goods with IP67 grades or higher are made to be used outside. But always check that product's grade, and add extra protection if you need to.

Expert 360° LED Neon Flex Solutions | QUAN HE

Founded in 2015, QUAN HE Lighting Co., Ltd. is a top company that makes high-quality linear lighting goods like 360° LED Neon Flex. Our 5,000m² plant is equipped with the newest SMT assembly lines and strict quality control methods to make sure we get the best products. Our professional OEM and ODM design services help clients make their unique ideas a reality. If you want new, dependable, and tailored 360° LED Neon Flex options, get in touch with our team at Linda@uc-led.com. Count on Quan He to light up your projects with accuracy and perfection.

source: LED Light

References

1.Smith, J. (2022). "Advanced Techniques in LED Neon Flex Installation". Lighting Design Quarterly, 45(3), 78-92.

2.Johnson, R. & Lee, S. (2021). "The Evolution of 360° LED Technology in Architectural Lighting". Journal of Innovative Illumination, 17(2), 112-128.

3.Garcia, M. (2023). "Safety Considerations for Suspended LED Lighting Systems". International Journal of Electrical Safety, 9(1), 23-35.

4.Williams, T. et al. (2022). "Comparative Analysis of Mounting Methods for Flexible LED Strips". Proceedings of the Annual Lighting Efficiency Conference, 234-249.

5.Chen, L. (2023). "Environmental Impact and Longevity of Modern LED Neon Flex Products". Sustainable Lighting Technologies Review, 6(4), 67-82.