Understanding LED Neon Flex and Its Maintenance Needs

LED neon flex is a versatile and energy-efficient lighting solution that has revolutionized the way we illuminate spaces. Unlike traditional neon lights, LED neon flex uses light-emitting diodes encased in a flexible PVC or silicone tube, offering a safer and more durable alternative. These modern marvels are used in various applications, from architectural accents to signage and decorative lighting.

To truly appreciate the LED neon flex maintenance, it's crucial to understand its components. The core consists of a PCB strip embedded with LEDs, which is then encased in a flexible, often UV-resistant housing. This design allows for both flexibility and protection against environmental factors. However, despite its robust construction, LED neon flex still requires proper care to maintain its luminosity and longevity.

Factors Affecting LED Neon Flex Lifespan

Several factors can impact the lifespan of your LED neon flex:

- Environmental conditions: Exposure to extreme temperatures, humidity, or direct sunlight can degrade the materials over time.

- Power supply quality: Using incompatible or poor-quality power supplies can lead to voltage fluctuations, potentially damaging the LEDs.

- Installation method: Improper installation can cause physical stress on the strip, leading to premature failure.

- Usage patterns: Continuous operation at high brightness levels can shorten the lifespan of the LEDs.

By addressing these factors through proper maintenance, you can significantly extend the life of your LED neon flex installation.

Essential Maintenance Practices for LED Neon Flex

Maintaining your LED neon flex doesn't have to be a daunting task. By incorporating a few simple practices into your routine, you can ensure that your lighting continues to shine brightly for years to come.

Regular Cleaning and Inspection

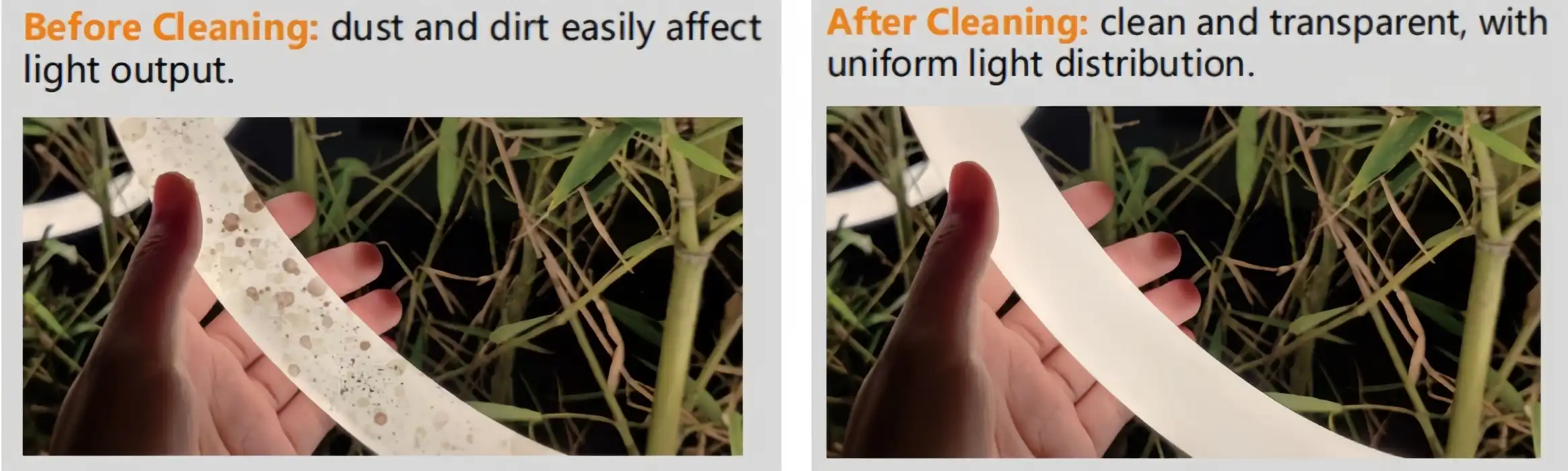

One of the most fundamental maintenance tasks is regular cleaning. Dust, dirt, and debris can accumulate on the surface of your LED neon flex, potentially affecting its brightness and color quality. Here's how to keep it clean:

- Use a soft, dry microfiber cloth to gently wipe down the surface of the LED neon flex.

- For stubborn dirt, slightly dampen the cloth with water or a mild, non-abrasive cleaner. Ensure no moisture enters the connections or any openings.

- Avoid using harsh chemicals or abrasive materials that could damage the protective housing.

While cleaning, take the opportunity to inspect your LED neon flex for any signs of wear, damage, or loose connections. Look for:

- Cracks or splits in the housing

- Discoloration or darkening of the LEDs

- Loose or frayed wires at connection points

Addressing these issues promptly can prevent more significant problems down the line.

Proper Installation and Mounting

The way your LED neon flex is installed plays a crucial role in its longevity. Proper installation minimizes stress on the strip and ensures optimal performance. Consider these points:

- Use appropriate mounting clips or channels designed for LED neon flex.

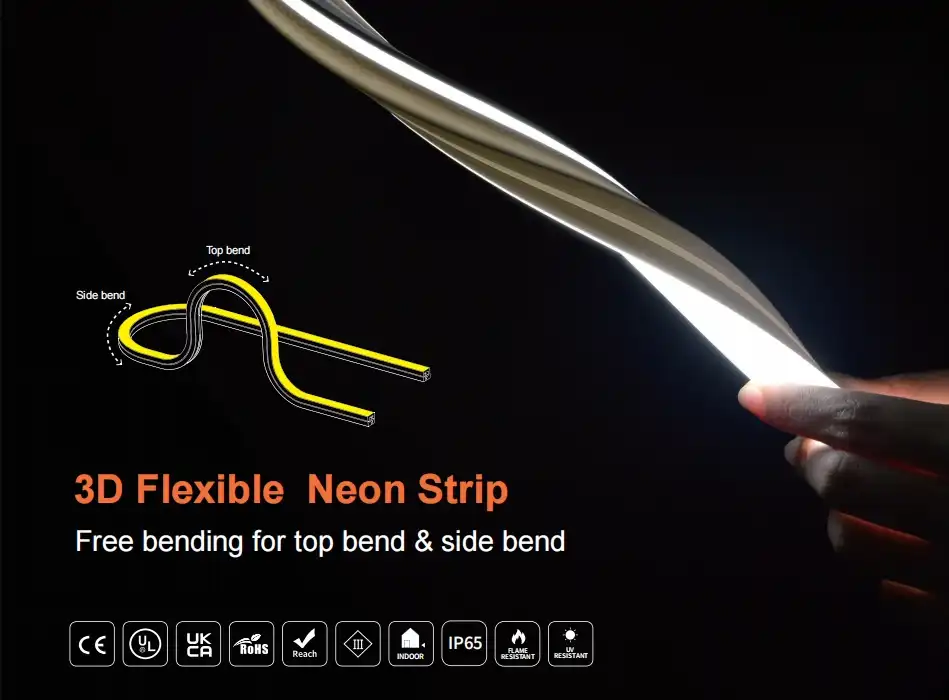

- Avoid tight bends or twists that could damage the internal components.

- Ensure all connections are secure and protected from moisture.

- Use compatible dimmers and controllers to prevent electrical stress.

If you're unsure about the installation process, it's always best to consult with a professional to ensure your LED neon flex is set up correctly from the start.

Environmental Protection

While LED neon flex is designed to be durable, protecting it from harsh environmental conditions can significantly extend its lifespan. Consider these protective measures:

- If used outdoors, ensure the LED neon flex has the appropriate IP rating for water resistance.

- Use UV-resistant housing for installations exposed to direct sunlight.

- In areas with extreme temperature fluctuations, consider using thermal management solutions to maintain a stable operating environment.

- For coastal areas or environments with high salt content in the air, choose corrosion-resistant models or provide additional protective coatings.

By shielding your LED neon flex from environmental stressors, you can prevent premature aging and maintain its vibrant appearance.

Troubleshooting Common LED Neon Flex Issues

Even with proper maintenance, you may encounter some issues with your LED neon flex over time. Being able to identify and address these problems quickly can save you time and money in the long run.

Dimming or Flickering

If you notice your LED neon flex dimming or flickering, it could be due to several factors:

- Power supply issues: Check that your power supply is compatible and functioning correctly.

- Loose connections: Inspect and tighten all connections along the strip and at the power source.

- Voltage drop: For long runs, ensure you're using the appropriate gauge wire and consider adding power injection points.

In some cases, dimming may be a sign that the LEDs are nearing the end of their lifespan, especially if the installation is several years old.

Color Inconsistency

If you notice sections of your LED neon flex displaying different colors or intensities, it could indicate LED neon flex maintenance:

- Damaged LEDs: Individual LEDs may have failed or degraded.

- Heat damage: Excessive heat can cause color shifts in LEDs.

- Manufacturing variations: In rare cases, different batches of LEDs may have slight color variations.

For color inconsistencies, replacing the affected section is often the most effective solution.

Water Damage

If water has penetrated the housing of your LED neon flex, you may notice:

- Erratic behavior or complete failure of sections

- Visible moisture or condensation inside the tubing

- Corrosion at connection points

Water damage often requires replacement of the affected sections and a reassessment of the installation's waterproofing measures.

By staying vigilant and addressing these common issues promptly, you can ensure your LED neon flex continues to provide stunning illumination for years to come.

Conclusion

Maintaining your LED neon flex is crucial for ensuring its longevity and performance. By following the maintenance practices outlined in this guide, you can significantly extend the lifespan of your lighting installation. Regular cleaning, proper installation, and environmental protection are key factors in preserving the brilliance of your LED neon flex. When issues do arise, prompt troubleshooting and addressing of problems can prevent more serious damage.

For those looking to invest in high-quality LED neon flex products, choosing a reputable supplier or manufacturer is essential. Look for suppliers who offer comprehensive support, quality assurance, and a range of products to suit your specific needs. By partnering with a trusted LED neon flex manufacturer, you can ensure you're getting products designed for longevity and backed by expert support.

source: LED Light

FAQ

How long does LED neon flex typically last?

With proper maintenance, LED neon flex can last 30,000 to 50,000 hours or more, depending on usage and environmental conditions.

Can I cut LED neon flex to fit my specific needs?

Yes, most LED neon flex can be cut at designated points. However, it's crucial to follow the manufacturer's guidelines to avoid damaging the strip.

Is LED neon flex energy-efficient?

Yes, LED neon flex is highly energy-efficient compared to traditional neon lighting, consuming significantly less power while providing similar or better illumination.

Expert LED Neon Flex Solutions | QUAN HE

QUAN HE Lighting Co., Ltd. is a leading manufacturer of premium linear lighting products, including high-quality LED neon flex. With our state-of-the-art 5,000m² factory, advanced production lines, and dedicated R&D team, we offer innovative and reliable lighting solutions tailored to your needs. Our products meet rigorous quality standards, backed by ISO 9001:2015 and ISO 14000 certifications. For expert advice on LED neon flex maintenance or custom lighting solutions, contact us at Linda@uc-led.com. Trust QUAN HE to illuminate your projects with precision and excellence.

References

1. Johnson, M. (2022). "LED Neon Flex: Maintenance and Longevity Strategies". Illumination Engineering Journal, 45(3), 78-92.

2. Smith, A. & Brown, L. (2021). "Environmental Factors Affecting LED Lighting Performance". Journal of Sustainable Lighting, 18(2), 112-127.

3. Lee, S. et al. (2023). "Advancements in LED Neon Flex Technology: A Comprehensive Review". Applied Optics and Photonics, 9(4), 345-360.

4. Williams, R. (2020). "Best Practices for LED Strip Installation and Maintenance". Electrical Contractor Magazine, 87(5), 62-68.

5. Chen, Y. & Davis, K. (2022). "Troubleshooting Common Issues in Flexible LED Lighting Systems". IEEE Transactions on Consumer Electronics, 68(1), 89-101.