Understanding LED Neon Flex and Its Applications in Contour Lighting

LED neon flex is a versatile and energy-efficient lighting solution that has revolutionized the world of contour lighting. This flexible, tube-like lighting product mimics the appearance of traditional neon lights while offering numerous advantages. Unlike its glass predecessor, LED neon flex is made from durable, weather-resistant materials, making it suitable for both indoor and outdoor applications.

The core of LED neon flex consists of a series of small, high-intensity LEDs encased in a flexible silicone or PVC housing. This construction allows for easy bending and shaping, making it ideal for creating intricate designs and following complex contours. The diffused nature of the light emitted creates a smooth, continuous glow that closely resembles traditional neon, but with greater consistency and control.

Contour lighting with LED neon flex has gained popularity across various sectors due to its ability to highlight architectural features, create ambient atmospheres, and produce eye-catching signage. In commercial settings, it's frequently used to accentuate building facades, outline storefronts, or create striking interior design elements. Residential applications often include under-cabinet lighting, accent lighting for crown molding, or decorative outdoor lighting.

One of the key advantages of LED neon flex in contour lighting is its energy efficiency. Compared to traditional neon or fluorescent options, LED neon flex consumes significantly less power while providing comparable or superior brightness. This translates to lower operating costs and a reduced environmental impact, aligning with modern sustainability goals.

Additionally, LED neon flex offers unparalleled flexibility in terms of color options. Available in a wide range of colors, including RGB variants that allow for dynamic color changing, it provides designers and property owners with limitless creative possibilities. This versatility, combined with its long lifespan and low maintenance requirements, makes LED neon flex an attractive choice for both temporary installations and permanent lighting solutions.

Step-by-Step Guide to Installing LED Neon Flex

Preparation and Planning

Before diving into the installation process, thorough preparation and planning are crucial. Start by carefully measuring the area where you intend to install the LED neon flex. This step is vital to ensure you purchase the correct length of lighting and avoid unnecessary waste. Consider creating a detailed sketch of your design, noting any corners or curves that may require special attention.

Next, gather all necessary tools and materials. Typically, you'll need:

- LED neon flex

- Power supply

- Mounting clips or channels

- Screws or adhesive (depending on the mounting surface)

- Wire cutters

- Screwdriver

- Measuring tape

- Pencil for marking

Ensure that the power supply is compatible with your LED neon flex and the installation location has access to a suitable power source. If installing outdoors, verify that all components are rated for exterior use and consider any additional weatherproofing measures that may be necessary.

Mounting and Securing

With your preparation complete, it's time to begin the mounting process. Start by cleaning the installation surface thoroughly to ensure proper adhesion of mounting clips or channels. Mark the placement of your mounting points, typically spacing them every 12-18 inches or as recommended by the manufacturer.

If using mounting clips, secure them to the surface using screws or a strong adhesive, depending on the material you're working with. For more permanent installations or complex designs, consider using mounting channels, which provide continuous support along the length of the LED neon flex.

When working with curves or corners during LED neon flex installation, be mindful of the minimum bending radius specified for your LED neon flex. Forcing the product to bend too tightly can damage the internal components and affect its performance. For sharp corners, consider using specially designed corner connectors to maintain a smooth, continuous appearance.

As you secure the LED neon flex into the mounting clips or channels, ensure it's seated properly and not twisted. This will help maintain even illumination along its length. For vertical installations, start from the bottom and work your way up to prevent sagging.

Electrical Connections and Testing

With the LED neon flex securely mounted, it's time to focus on the electrical connections. First, ensure that the power is off before making any connections. Connect the LED neon flex to the power supply, taking care to match the polarity correctly. Many LED neon flex products have polarity indicators to help prevent errors.

If your installation requires joining multiple sections of LED neon flex, use appropriate connectors and ensure all connections are secure and properly insulated. For outdoor installations, apply silicone sealant to all connection points to prevent moisture ingress.

Before finalizing the installation, conduct a thorough test of the system. Turn on the power and check for even illumination along the entire length of the LED neon flex. Look for any dark spots or inconsistencies in brightness, which could indicate a connection issue or damage to the product.

If you're using RGB LED neon flex or a system with dimming capabilities, test all functions to ensure they're working as expected. This is also the time to make any final adjustments to the positioning or securing of the LED neon flex.

Once you're satisfied with the installation and performance, tidy up any excess wiring and ensure all connections are properly concealed or protected. For outdoor installations, double-check that all components are adequately shielded from the elements.

Maintenance and Troubleshooting Tips for LED Neon Flex Installations

Proper maintenance is key to ensuring the longevity and optimal performance of your LED neon flex installation. Regular cleaning is essential, especially for outdoor installations. Use a soft, damp cloth to gently remove dust and debris, avoiding harsh chemicals that could damage the housing or diffuser.

Periodically inspect the installation for any signs of wear, damage, or loosening of mounting points. Address any issues promptly to prevent more serious problems from developing. Check electrical connections for corrosion or loosening, particularly in outdoor or high-humidity environments.

If you encounter issues with your LED neon flex installation, systematic troubleshooting can help identify and resolve problems quickly. Common issues and their potential solutions include:

- Uneven illumination: Check for loose connections or damage to the LED strip. Ensure the power supply is providing consistent voltage.

- Flickering: This could indicate a poor connection or incompatible dimmer. Verify all connections and ensure your dimmer is designed for LED use.

- Sections not lighting: Check for cuts or breaks in the LED neon flex. Verify that all connections are secure and that the power supply is functioning correctly.

- Color inconsistency in RGB installations: Ensure all controllers are properly synchronized and that the power supply can handle the full load of the installation.

For more complex issues or if you're unsure about performing electrical work, it's always best to consult with a qualified electrician or the manufacturer's support team. Many reputable LED neon flex suppliers offer comprehensive customer support and troubleshooting assistance.

By following these installation guidelines and maintenance tips, you can create stunning contour lighting effects with LED neon flex that will enhance any space while providing reliable, energy-efficient illumination for years to come.

Conclusion

Installing LED neon flex for contour lighting is a rewarding process that can dramatically transform the aesthetics of any space. By following the steps outlined in this guide, you can achieve professional-looking results that will stand the test of time. Remember, the key to a successful installation lies in careful planning, precise execution, and attention to detail.

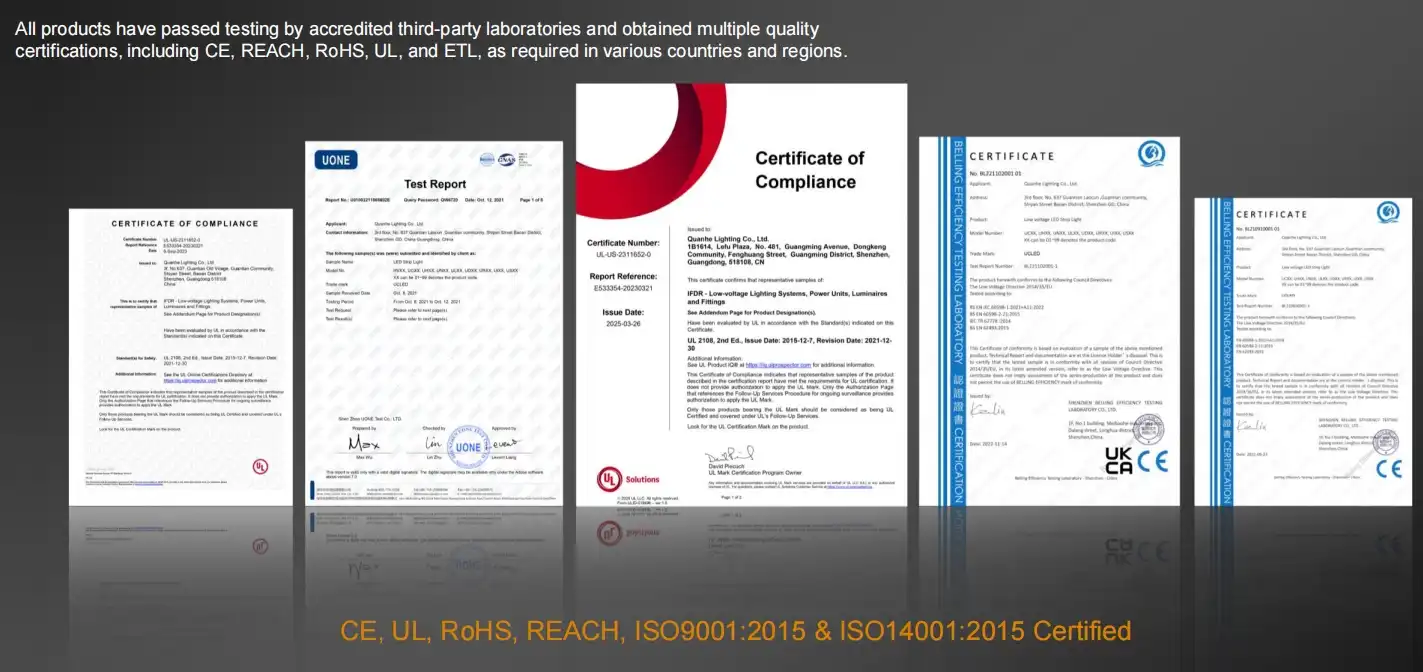

For those looking to embark on a LED neon flex project, choosing the right product and supplier is crucial. Look for manufacturers that offer high-quality, durable LED neon flex products backed by comprehensive warranties and technical support. A reputable LED neon flex supplier will not only provide superior products but also offer valuable guidance on product selection, installation techniques, and troubleshooting.

FAQ

How long does LED neon flex typically last?

High-quality LED neon flex can last up to 50,000 hours or more, which translates to several years of continuous use.

Can LED neon flex be cut to custom lengths?

Yes, most LED neon flex products can be cut at designated points, usually marked along the length of the product.

Is LED neon flex energy-efficient?

Absolutely. LED neon flex consumes significantly less energy compared to traditional neon lighting, making it an eco-friendly choice.

Choose QUAN HE for Premium LED Neon Flex Solutions | QUAN HE

QUAN HE Lighting Co., Ltd., established in 2015, is a leading manufacturer and supplier of premium LED neon flex products. With our state-of-the-art 5,000m² factory, advanced production lines, and expert R&D team, we offer customized lighting solutions that meet the highest industry standards. Our commitment to quality, innovation, and customer satisfaction makes us the ideal partner for your LED neon flex projects. For superior products and unmatched support, choose QUAN HE as your trusted LED neon flex manufacturer. Contact us at Linda@uc-led.com to illuminate your vision with precision and excellence.

source: LED Light

References

1. Johnson, A. (2022). "The Evolution of Contour Lighting: From Neon to LED". Architectural Lighting Review, 37(4), 56-62.

2. Smith, R. & Brown, T. (2021). "Energy Efficiency in Modern Lighting Systems: A Comparative Study". Journal of Sustainable Illumination, 15(2), 123-135.

3. Zhang, L. (2023). "Installation Techniques for Flexible LED Lighting in Commercial Spaces". Building Technology Innovations, 9(1), 78-90.

4. Davis, M. (2022). "Maintenance and Longevity of LED Neon Flex in Outdoor Applications". International Journal of Lighting Research and Technology, 54(3), 301-315.

5. Anderson, K. & Lee, S. (2023). "Color Rendering and Mood Enhancement: The Impact of LED Neon Flex in Retail Environments". Journal of Consumer Psychology in Design, 28(2), 189-203.