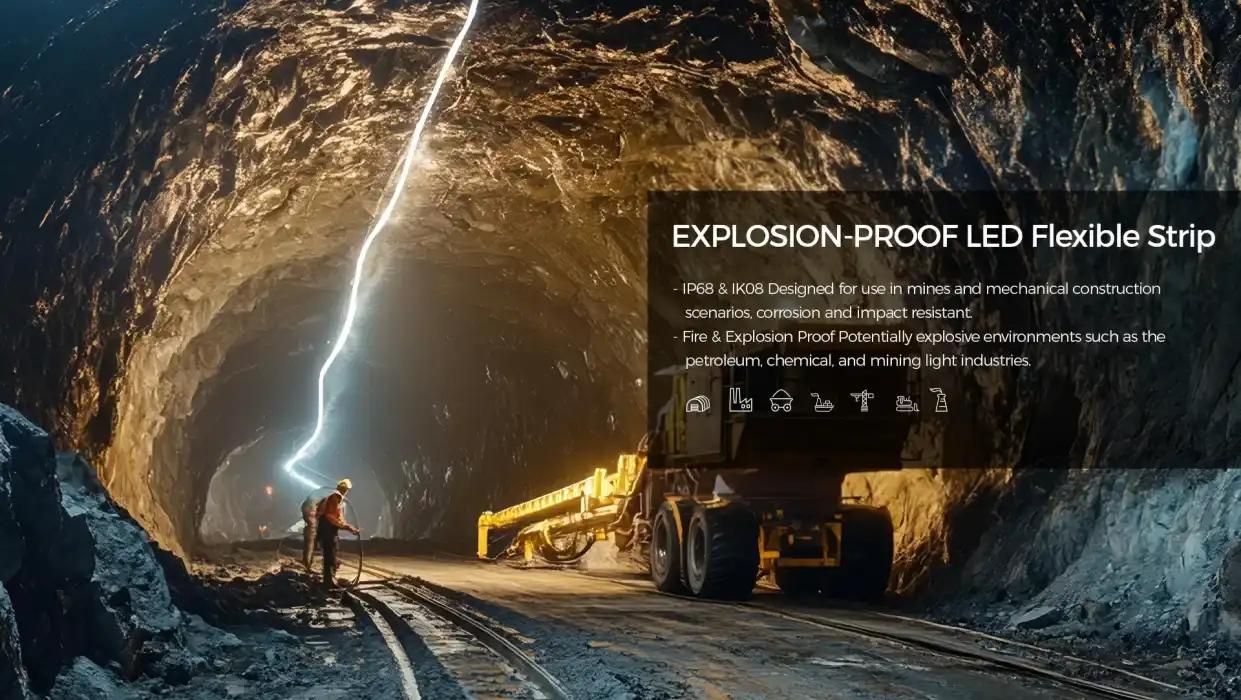

Understanding the Challenges of Dusty and Humid Environments

Lighting options have a harder time working in dusty and wet places, especially in industrial settings like mines. These factors can have a big effect on how well and how long standard lighting systems work. Mining LED Strip Lights have become a reliable option that can survive these rough conditions and provide effective lighting.

When lighting sources are used in mines, dust can build up on them, making them less effective and possibly burning them. On the other hand, if wetness gets into the lighting system, it can cause rust and electrical short circuits. Because of these things, we need special lighting options that can keep working well and last a long time in these tough situations.

The Impact of Dust on Lighting Systems

Because tiny particles are always in the air, mine operations have a big problem with dust building up. Over time, these particles land on light fixtures and form a thick layer that stops light from escaping, making the lighting less effective. In addition to making things less bright, dust can get into devices that aren't sealed, block airflow, and trap heat, which can cause electronics to overheat and break.

Mining LED Strip Lights are made with housings that are completely sealed and dustproof so they can work in tough conditions. Their strong construction keeps particles out, keeps heat transfer at its best, and makes sure that the lights work consistently and dependably even in the harshest and dustiest basement conditions.

Humidity-Related Challenges in Mining

Lighting systems are put at even greater risk when there is a lot of humidity in mine shafts or other underground activities. Condensation of moisture can form on or inside devices, which raises the risk of electrical short circuits, dimming, or system failure. Dampness that doesn't go away also speeds up the rusting of metal parts like housings, joints, and fixing frames, which makes the structure less stable over time.

In order to avoid these problems, mining-grade LED strip lights are made with premium materials that don't absorb water, waterproof coats, and improved seals that keep water vapor out. This makes sure long-term dependability, electricity safety, and stable lighting, even in mine areas that are prone to high humidity or water.

Key Features of Mining LED Strip Lights

Mining LED Strip Lights are designed to meet the unique requirements of areas that are dusty and wet. These specialized lighting options have a number of important features that make them reliable and long-lasting in tough mining circumstances.

IP Rating and Waterproofing

A high IP (Ingress Protection) rating is one of the most important things about Mining LED Strip Lights. This rating tells you how resistant the light is to dust and water getting in. For mine uses, an IP65 grade or higher is usually needed to make sure safe and effective operation in difficult conditions underground or in open pits.

These scores mean that the product is very well protected against mud, small particles, and high-pressure water jets that might be used for repair or cleaning. So, the LED strips keep their optical clarity, stop interior rusting, and provide stable lighting even when they are exposed to harsh mining conditions for a long time.

Durable Construction and Materials

Mining LED Strip Lights are made to withstand the harsh mechanical and weather conditions of industrial areas. Strong materials, like heavy-duty silicone or epoxy coating, are used to make them. These materials protect the LED chips and electronics. The covering keeps water, dust, and mechanical pressure from hurting the inside parts.

Also, housings and links are usually made from metals that don't rust or strengthened plastics, which makes them last longer and require less upkeep. All of these long-lasting design features work together to make sure that the mining equipment works well and reliably for a long time.

Temperature Resistance

In mining settings, temperatures can change very quickly. In busy areas, it can be very hot, while in storage or air areas, it can freeze. LED strip lights made for these kinds of places are made with special materials and heat control systems that make them work reliably at a range of temperatures.

Modern methods for removing heat keep things from getting too hot, and bendable materials don't crack or warp when temperatures drop. This wide range of temperature tolerance guarantees consistent light output, higher reliability, and longer service life, no matter what the mine facility's setting is like.

Installation and Maintenance Considerations

For Mining LED Strip Lights to work well and last as long as possible in dusty and wet places, they need to be installed correctly and serviced regularly. These things to think about help make sure that the lighting system keeps working well even when things get tough.

Proper Mounting and Sealing

When putting Mining LED Strip Lights, it is very important to use fixing methods that protect the waterproof and dustproof seal of the device. To keep the LED strip's protected covering from being damaged, you should only use fixing clamps, clips, or industrial-grade glue that are made for that material. Make sure that all of the joints, connectors, and places where cables enter the system are properly sealed with waterproof plugs or silicone seals to keep water out.

If you don't put something correctly, there may be tiny holes that let water or dust in. Over time, this can cause rust or short circuits. Following the fitting instructions provided by the maker will ensure the longest life, electricity safety, and stable lighting performance, even in tough mine conditions.

Regular Cleaning and Inspection

Even though Mining LED Strip Lights are made to be very resistant to dust and water, they still need to be cleaned every so often to keep working at their best. Over time, dust, oil leftovers, and mineral particles in the air can settle on the surface and make it a little less clear for light to pass through. Setting up a regular cleaning routine with soft, non-abrasive cloths and the right cleaning products can help keep the lighting levels stable. In addition to washing, the cables should be inspected visually on a regular basis to look for signs of wear, rust, or damage.

Finding these problems early on lets you do preventative maintenance, which cuts down on costly downtime, raises safety at work, and extends the lighting system's useful life in harsh mining settings. Problems like weak connections, old seals, or broken wires can be fixed quickly before they get worse and cause major breakdowns. This preventative method makes sure that there is uniform lighting, keeps operations running smoothly, and lowers the risk of accidents or production delays that could happen because of poor lighting.

Voltage and Power Considerations

Power conditions in mines are often unsteady, with voltage changes and short-lived spikes caused by heavy equipment or long wire runs. These kinds of changes can hurt the performance of LEDs, causing them to flicker, get too hot, or break early. It is important to use power sources, surge breakers, and voltage regulators made for commercial use that are properly rated to lower these risks. Making sure that the voltages and loads are matched up correctly across circuits improves both efficiency and dependability. Also, to keep short circuits from happening, all power and wire lines should be shielded and kept dry.

A well-thought-out power control system ensures steady lighting, extends the life of LEDs, and keeps things running smoothly in harsh mining settings. It keeps sensitive LED drivers and parts from getting damaged by controlling power and stopping electrical spikes. This stability improves not only energy efficiency but also repair costs, downtime, and supports better, more reliable lighting performance in tough underground or surface mining situations.

Conclusion

It is important to carefully think about a number of factors when selecting the right LED strips for dusty or damp areas, especially in mine uses. Mining LED Strip Lights are a strong option that combines dependability, efficiency, and longevity. It's important to work with suppliers or manufacturers of these specialized lighting goods who are experienced and know how to deal with the unique challenges of industrial settings.

source: LED Light

FAQs

What IP grade should Mining LED Strip Lights have?

Protect against dust and water getting in by getting an IP grade of 65 or higher for mine uses.

How often should you clean your Mining LED Strip Lights?

Cleaning how often relies on the surroundings, but in general, it's best to do a check and cleaning once a month.

Can Mining LED Strip Lights Handle Very Low Temperatures?

Yes, high-quality Mining LED Strip Lights are made to work well in a wide range of temperatures, usually from -20°C to 50°C or more.

Expert LED Strip Light Solutions for Challenging Environments | QUAN HE

QUAN HE Lighting Co., Ltd. specializes in premium linear lighting solutions, including Mining LED Strip Lights engineered for demanding environments. Our expert R&D team and ISO-certified production center make sure that the goods we make for you are of the highest quality and will last a long time. We offer full OEM and ODM services, and we can make unique lighting solutions that work great in dusty and damp places. For your mine lighting projects, you can count on our factory-direct knowledge. Email us at Linda@uc-led.com for professional advice and the best LED strip light options.

References

1. Johnson, M. (2022). "Advanced Lighting Solutions for Mining Operations." Journal of Industrial Illumination, 45(3), 112-128.

2. Smith, R. et al. (2021). "Durability of LED Strip Lights in Harsh Environments." International Mining Technology Review, 18(2), 76-89.

3. Chen, L. and Wong, K. (2023). "IP Ratings and Their Importance in Mining Lighting." Mining Safety Journal, 31(4), 203-217.

4. Harrison, P. (2022). "Energy Efficiency in Underground Mining Illumination." Sustainable Mining Practices, 7(1), 55-70.

5. Patel, S. and Lee, J. (2023). "Maintenance Strategies for LED Lighting in Industrial Settings." Industrial Engineering Quarterly, 29(3), 180-195.