Introducing Flexible LED Strips: Features and Applications

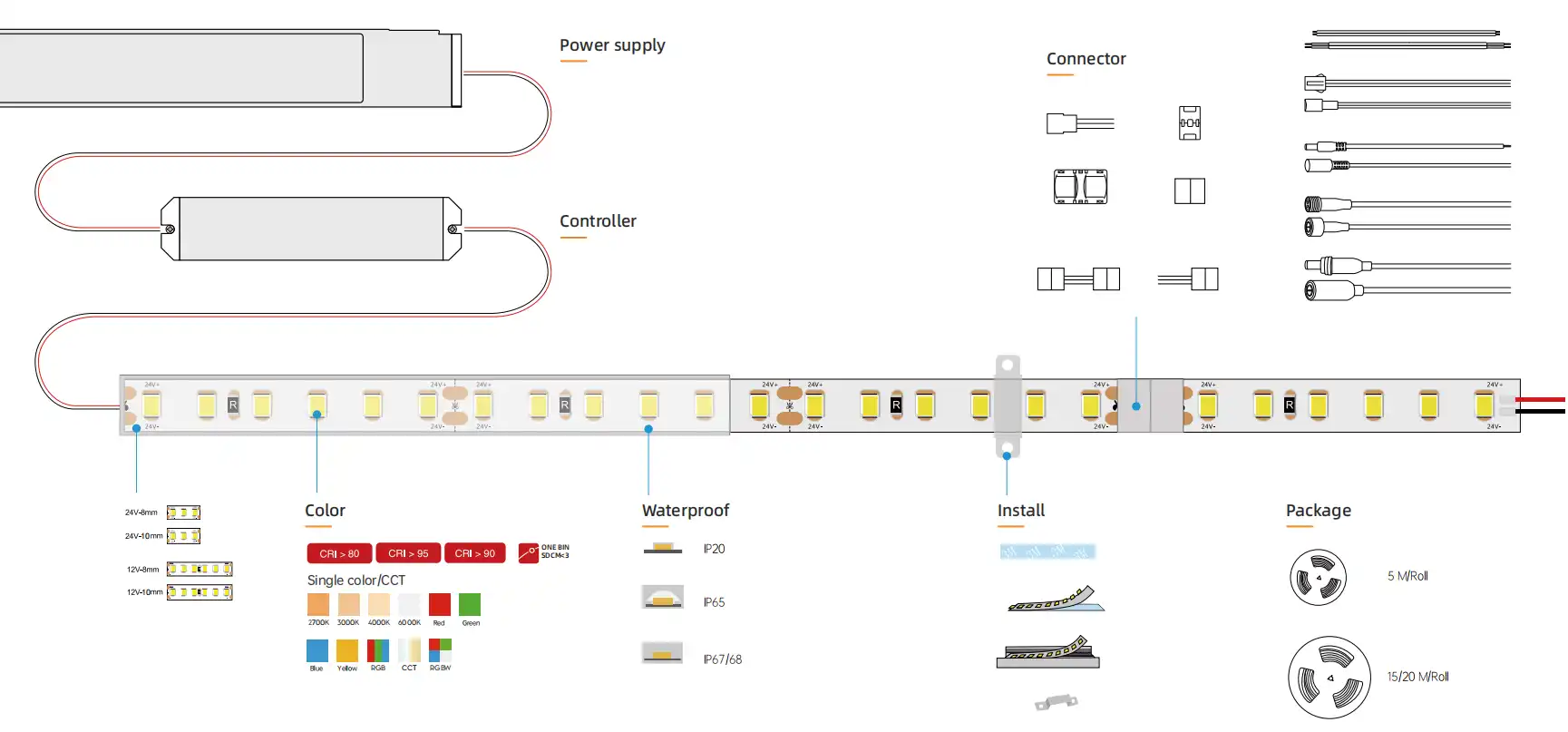

Flexible LED strips, also known as LED tape or ribbon lights, have revolutionized the lighting industry with their versatility and ease of use. These thin, bendable strips are composed of a series of small LED chips mounted on a flexible circuit board, typically encased in a protective silicone or epoxy coating.

Key Features of Flexible LED Strips

Flexibility is the hallmark feature of these LED strips, allowing them to conform to various shapes and contours. This malleability makes them suitable for a wide range of applications, from accent lighting in curved architectural features to backlighting for mirrors and cabinets. Additionally, flexible LED strips are often cuttable at designated intervals, enabling customization to fit specific space requirements.

Most flexible LED strips are available in various color temperatures and RGB options, providing users with the ability to create diverse lighting atmospheres. Their low profile design makes them ideal for concealed lighting applications, where space is at a premium. Many models also come with adhesive backing, simplifying the installation process.

Applications of Flexible LED Strips

The adaptability of flexible LED strips makes them suitable for numerous applications across residential, commercial, and industrial settings. In homes, they're commonly used for under-cabinet lighting in kitchens, cove lighting in living rooms, and accent lighting for staircases. In commercial spaces, flexible LED strips are popular for creating ambiance in restaurants, highlighting product displays in retail stores, and providing subtle illumination in theaters and cinemas.

Outdoor applications are also possible with weatherproof flexible LED strips, which can be used for landscape lighting, outlining building contours, or illuminating pathways. In the automotive industry, these strips are often used for interior ambient lighting and exterior accent lighting.

Exploring Rigid Strip Lights: Characteristics and Uses

Rigid strip lights, as the name suggests, are inflexible LED lighting solutions that offer a different set of advantages compared to their flexible counterparts. These strips consist of LED chips mounted on a rigid PCB board, often housed in an aluminum extrusion that serves as both a heat sink and a protective casing.

Distinctive Features of Rigid Strip Lights

The primary characteristic of rigid strip lights is their sturdy construction, which provides enhanced durability and heat dissipation. This robust design makes them suitable for applications where a more substantial lighting fixture is required. Rigid strips typically offer higher lumen output compared to flexible strips, making them ideal for task lighting and areas needing bright illumination.

Rigid strip lights and Flexible LED Strip lights often come in pre-cut lengths, which can be an advantage in projects requiring precise measurements. They usually feature a sleek, linear design that can contribute to a modern, minimalist aesthetic. Many models are available with diffusers or lenses that can alter the beam angle and light distribution, offering greater control over the lighting effect.

Common Applications for Rigid Strip Lights

The linear nature and higher light output of rigid strip lights make them particularly suited for certain applications. In commercial settings, they're often used for overhead lighting in offices, retail stores, and warehouses. Their ability to provide uniform, high-quality light makes them popular for display case lighting in museums and galleries.

In residential spaces, rigid strip lights are frequently used for under-cabinet task lighting in kitchens, vanity lighting in bathrooms, and as primary light sources in closets and pantries. Their sturdy construction also makes them suitable for outdoor applications such as patio and deck lighting, provided they have the appropriate IP rating for weather resistance.

Making the Right Choice: Factors to Consider

Choosing between flexible LED strips and rigid strip lights depends on several factors. Understanding these considerations will help you make an informed decision that best suits your lighting needs.

Installation Requirements

The installation process differs significantly between flexible and rigid strip lights. Flexible strips are generally easier to install, especially in tight spaces or on curved surfaces. They can be cut to size and often come with an adhesive backing for simple mounting. Rigid strips, while more challenging to install in complex layouts, offer a more professional finish and are easier to mount in straight lines without sagging.

Light Output and Distribution

Rigid strip lights typically offer higher lumen output and more consistent light distribution compared to flexible strips. This makes them more suitable for primary lighting applications or areas requiring bright, uniform illumination. Flexible strips, while capable of providing ample light, are often better suited for accent or ambient lighting scenarios.

Durability and Longevity

Rigid strip lights, with their robust construction and superior heat dissipation, often have a longer lifespan and can withstand more demanding environments. Flexible strips, while durable in their own right, may be more susceptible to damage from bending or environmental factors in certain applications.

Aesthetics and Design Flexibility

Flexible LED strips offer unparalleled design flexibility, allowing for creative lighting solutions in complex architectural features or irregular spaces. Rigid strips provide a more structured, linear aesthetic that can complement modern interior designs and create clean, crisp lighting effects.

Cost Considerations

Generally, flexible LED strips tend to be more cost-effective, especially for larger installations. However, the total cost should be evaluated based on the specific project requirements, including installation complexity, power supplies, and any additional accessories needed.

Conclusion

Both flexible LED strips and rigid strip lights have their unique strengths, and the best choice depends on your specific lighting requirements, installation environment, and design preferences. Flexible strips excel in versatility and ease of installation, making them ideal for accent lighting and complex layouts. Rigid strips offer higher light output and durability, suitable for primary lighting applications and professional installations.

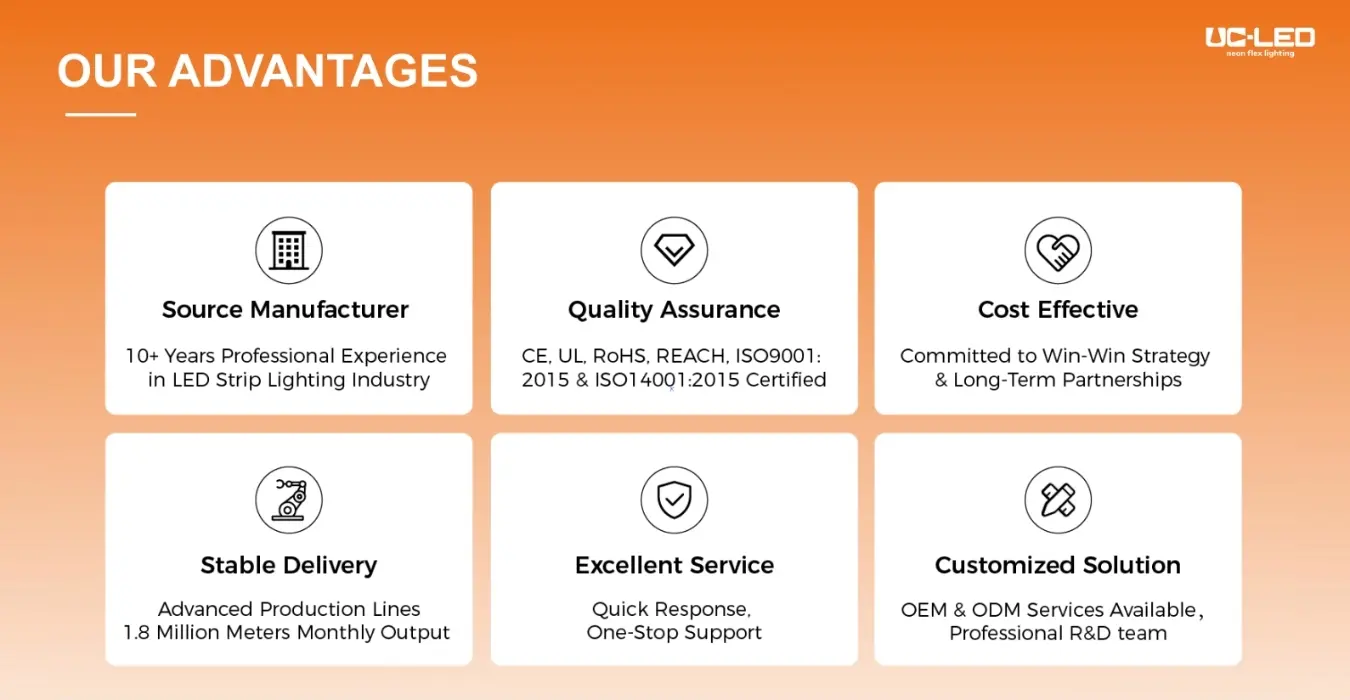

When selecting an LED strip supplier or manufacturer, consider factors such as product quality, customization options, and technical support. Look for a reputable LED strip light manufacturer that can provide tailored solutions to meet your project's unique needs.

source: LED Light

FAQ

Are flexible LED strips waterproof?

Many flexible LED strips are available with waterproof ratings, making them suitable for outdoor or damp environments. However, not all are waterproof, so it's essential to check the IP rating before purchase.

Can rigid strip lights be cut to size?

While some rigid strip lights can be cut at designated points, many are designed to be used at their full length. Always consult the manufacturer's specifications before attempting to cut rigid strips.

Which type of LED strip is better for under-cabinet lighting?

Both types can work well for under-cabinet lighting. Flexible strips are easier to install in tight spaces, while rigid strips often provide brighter, more uniform task lighting.

Expert LED Lighting Solutions | QUAN HE

QUAN HE Lighting Co., Ltd. is a leading manufacturer of premium linear lighting products, including flexible LED strips and rigid strip lights. With over a decade of experience, our state-of-the-art 5,000m² factory equipped with advanced SMT assembly lines ensures top-quality products. We offer customized OEM and ODM services, backed by our expert R&D team and ISO-certified manufacturing processes. For innovative, reliable LED lighting solutions tailored to your project needs, contact our team at Linda@uc-led.com.

References

1. Johnson, M. (2022). "Comparative Analysis of Flexible and Rigid LED Lighting Solutions." Journal of Illumination Engineering, 45(3), 78-92.

2. Smith, R. & Brown, T. (2021). "Energy Efficiency in Modern Lighting: LED Strip Applications." Sustainable Building Technologies, 18(2), 112-125.

3. Lee, S. et al. (2023). "Advancements in LED Strip Technology: Flexibility vs. Rigidity." International Journal of Lighting Research and Technology, 55(1), 23-37.

4. Williams, A. (2020). "Architectural Lighting Design: Integrating Flexible and Rigid LED Strips." Building Design & Construction Magazine, 36(4), 56-69.

5. Chen, H. & Wang, L. (2022). "Durability and Performance of Flexible LED Strips in Various Environmental Conditions." IEEE Transactions on Components, Packaging and Manufacturing Technology, 12(6), 1015-1028.