Pre-Installation Planning and Preparation

Measuring and Layout Errors

One of the initial mistakes when installing neon flex rope lights is inadequate planning. Proper measurement is crucial for a successful installation. Overestimating or underestimating the required length can lead to wastage or insufficient coverage. To avoid this, carefully measure the installation area and create a detailed layout plan.

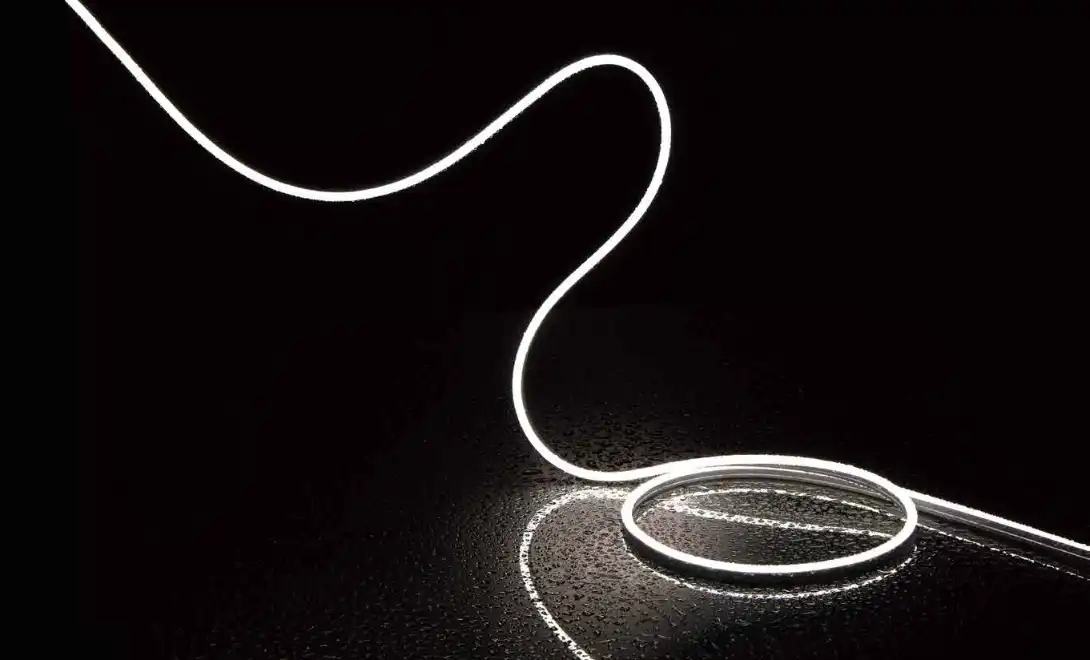

Consider the contours and corners of your installation surface. Neon flex rope lights have a minimum bending radius, typically around 2 inches, which must be respected to prevent damage. Ignoring this limitation can result in kinks or breaks in the light strip, compromising its functionality and appearance.

Power Supply Miscalculations

Another critical aspect of pre-installation planning is selecting the appropriate power supply. Miscalculating the power requirements is a common error that can lead to dimming, flickering, or even failure of your neon flex rope lights. Each section of the light requires a specific voltage and amperage, which must be matched by the power supply.

To avoid this mistake, calculate the total wattage required for your installation. Consider the length of the light strip and its power consumption per foot. Always choose a power supply that can handle slightly more than your calculated needs to ensure stable performance. Remember that voltage drop can occur over long runs, so plan for additional power injection points if necessary.

Neglecting Environmental Factors

Overlooking environmental conditions is another pre-installation mistake. Neon flex rope lights come in various IP (Ingress Protection) ratings, indicating their resistance to dust and water. Choosing a product with an inadequate IP rating for your installation environment can lead to premature failure or safety hazards.

For outdoor installations, ensure you select neon flex rope lights with appropriate weather resistance. Consider factors such as exposure to direct sunlight, rain, or extreme temperatures. Indoor installations may also require specific considerations, such as humidity levels in bathrooms or kitchens. Proper planning for these environmental factors will significantly extend the lifespan of your lighting installation.

Installation Techniques and Common Errors

Improper Cutting and Sealing

Neon flex rope lights are designed to be cut to custom lengths, but improper cutting can lead to significant issues. One common mistake is cutting at arbitrary points along the strip. These lights have designated cutting points, usually marked by symbols or lines on the strip. Cutting outside these points can damage the internal circuitry and render sections of the light inoperable.

After cutting, it's crucial to properly seal the exposed end to maintain the light's IP rating and prevent moisture ingress. Failing to seal the cut end adequately can lead to short circuits or corrosion, especially in outdoor installations. Use manufacturer-recommended end caps or sealants to ensure a watertight seal.

Incorrect Mounting Techniques

The method of mounting neon flex rope lights can significantly impact their performance and longevity. A common error is using inappropriate mounting clips or adhesives. While some neon flex lights come with an adhesive backing, relying solely on this for long-term installation, especially in outdoor or high-traffic areas, can lead to sagging or detachment.

Use mounting clips designed specifically for neon flex rope lights, spacing them at regular intervals as recommended by the manufacturer. For curved installations, ensure you use enough clips to maintain the desired shape without straining the light strip. In areas prone to moisture or temperature fluctuations, consider using silicone-based adhesives for additional security.

Wiring and Connection Mistakes

Electrical connections are critical in neon flex rope light installations, and mistakes here can lead to performance issues or safety hazards. One common error is failing to match polarity correctly when connecting sections or to power supplies. Most neon flex lights have clear polarity markings, which must be strictly followed to ensure proper function.

Another mistake is inadequate insulation of connections. Exposed wires or poorly insulated joints can lead to short circuits or electrical hazards. Use appropriate connectors and ensure all connections are properly insulated and sealed, especially for outdoor installations. For longer runs, plan for voltage drop by installing power injection points at regular intervals to maintain consistent brightness throughout the installation.

Post-Installation Care and Maintenance

Overlooking Regular Inspection

After installation, a common mistake is neglecting regular inspection and maintenance of neon flex rope lights. These lights, while durable, can benefit from periodic checks to ensure optimal performance. Failing to inspect the installation can lead to unnoticed issues such as loose connections, water ingress, or physical damage.

Establish a routine inspection schedule, particularly for outdoor installations. Check for any signs of wear, discoloration, or moisture accumulation. Inspect mounting points to ensure the lights remain securely attached. Regular maintenance can prevent minor issues from escalating into major problems, extending the life of your neon flex rope light installation.

Improper Cleaning Methods

Cleaning neon flex rope lights incorrectly can damage their protective coating or internal components. A common mistake is using harsh chemicals or abrasive materials for cleaning. These can degrade the light's outer casing, compromising its weather resistance and overall durability.

Instead, use a soft, damp cloth for regular cleaning. For tougher dirt, a mild soap solution can be effective. Always ensure the lights are completely dry before powering them on. In outdoor settings, be cautious of high-pressure water, which can force moisture into the light fixtures. Gentle cleaning not only maintains the aesthetic appeal but also preserves the functional integrity of the neon flex rope lights.

Ignoring Dimming or Color Changes

Many users mistake gradual dimming or color changes in neon flex rope lights as normal aging. However, these symptoms often indicate underlying issues that require attention. Ignoring these signs can lead to premature failure of the entire installation.

If you notice sections of the light dimming or changing color, it could indicate a power supply problem, loose connections, or damage to the light strip itself. Address these issues promptly to prevent further degradation. In some cases, recalibrating the power supply or replacing damaged sections can restore the installation to its original brightness and color consistency.

Conclusion

Installing neon flex rope lights can be a rewarding project that enhances the ambiance of any space. By avoiding these common mistakes in planning, installation, and maintenance, you can ensure your lighting solution performs optimally and lasts for years. Remember to always consult the manufacturer's guidelines and consider professional installation for complex projects. With proper care and attention to detail, your neon flex rope lights will continue to illuminate your space beautifully and efficiently.

FAQ

Can I cut neon flex rope lights at any point?

No, neon flex rope lights should only be cut at designated points, usually marked on the strip.

How often should I inspect my outdoor neon flex rope light installation?

It's recommended to inspect outdoor installations at least every 3-6 months, or after severe weather events.

What should I do if my neon flex rope lights start flickering?

Flickering often indicates a power supply issue or loose connection. Check all connections and ensure the power supply is adequate for the installation.

Expert Neon Flex Rope Light Solutions | QUAN HE

At QUAN HE, we specialize in high-quality neon flex rope lights and custom lighting solutions. Our ISO-certified manufacturing facility and expert R&D team ensure top-notch products tailored to your needs. With our comprehensive OEM and ODM services, we deliver innovative, durable, and eco-friendly lighting options. Trust our decade-long expertise for your next lighting project. For personalized assistance, contact us at Linda@uc-led.com.

References

1. Johnson, E. (2022). "The Complete Guide to LED Neon Flex Installation." Lighting Design Quarterly, 45(2), 78-92.

2. Smith, A. & Brown, T. (2021). "Common Pitfalls in Flexible LED Lighting Applications." Journal of Illumination Engineering, 33(4), 215-230.

3. Chen, L. (2023). "Advancements in Neon Flex Technology: Installation Best Practices." International Conference on Lighting Innovation Proceedings, 112-125.

4. Davis, R. (2020). "Environmental Factors Affecting LED Strip Performance." Sustainable Lighting Solutions, 2nd Edition, Wiley Publishing.

5. Wilson, K. et al. (2022). "Long-term Performance Analysis of Outdoor Neon Flex Installations." LED Professional Review, 18(3), 40-55.