Understanding Flexible LED Strips and Their Applications

What Are Flexible LED Strips?

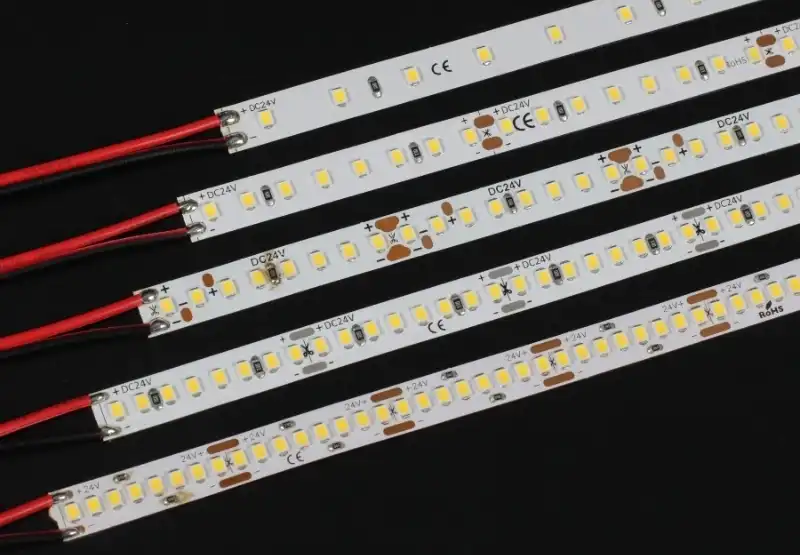

Flexible LED strips, also known as LED tape or ribbon lights, are thin, bendable circuits embedded with light-emitting diodes (LEDs). These versatile lighting solutions consist of a flexible printed circuit board (FPCB) with surface-mounted LEDs, typically encased in a silicone or PVC sheath for protection. The flexibility of these strips allows them to conform to various shapes and contours, making them ideal for illuminating curved surfaces.

Key Features of Flexible LED Strips

Flexible LED strips offer several advantages that make them suitable for a wide range of applications:

- Adaptability: They can be bent and shaped to fit curved surfaces without compromising light output.

- Customizable length: Most strips can be cut at designated points, allowing for precise fitting.

- Low profile: Their slim design makes them unobtrusive and easy to conceal.

- Energy efficiency: LED technology consumes less power compared to traditional lighting options.

- Long lifespan: Quality LED strips can last up to 50,000 hours or more.

- Color options: Available in single colors, RGB, or RGBW configurations for versatile lighting effects.

Common Applications for Curved Surfaces

Flexible LED strips are widely used in various settings to illuminate curved surfaces:

- Architectural lighting: Highlighting curved facades, domes, or arches in buildings.

- Retail displays: Illuminating curved showcases or product displays.

- Hospitality: Creating ambient lighting in curved bar counters or reception desks.

- Automotive: Interior accent lighting for curved dashboard elements.

- Home decor: Backlighting curved mirrors or illuminating rounded furniture pieces.

- Signage: Outlining curved lettering or logos in commercial signs.

Factors to Consider When Choosing Flexible LED Strips for Curved Surfaces

Bend Radius and Flexibility

The bend radius is a critical factor when selecting flexible LED strips for curved surfaces. It refers to the minimum radius at which the strip can be bent without damaging the components or affecting performance. A smaller bend radius indicates greater flexibility, allowing the strip to conform to tighter curves.

When choosing a flexible LED strip for a curved surface, consider the following:

- Measure the curvature of the surface you intend to illuminate.

- Choose a strip with a bend radius smaller than or equal to the tightestcurve you need to navigate.

- Keep in mind that strips with more LEDs per meter may have a larger bend radius due to the increased density of components.

LED Density and Light Output

The number of LEDs per meter (LED density) affects both the light output and the flexibility of the strip. Higher LED densities generally provide more uniform illumination but may limit flexibility. Consider these points:

- For gentle curves, strips with 60 LEDs per meter may suffice.

- For tighter curves or more uniform lighting, opt for strips with 120 or more LEDs per meter.

- Balance LED density with the desired brightness and flexibility requirements of your project.

IP Rating and Environmental Considerations

The Ingress Protection (IP) rating indicates the strip's resistance to dust and water. For curved surfaces in different environments, choose an appropriate IP rating:

- IP20: Suitable for dry indoor applications.

- IP65: Resistant to dust and low-pressure water jets, ideal for humid indoor areas or sheltered outdoor use.

- IP67 or IP68: Fully waterproof, suitable for outdoor applications or areas exposed to water.

Power and Control Options

Consider the power requirements and control options for your flexible LED strip installation:

- Ensure your power supply can handle the total wattage of the LED strip length you plan to use.

- For long runs on curved surfaces, consider using multiple power injection points to maintain consistent brightness.

- Choose between single-color, RGB, or RGBW strips based on your desired lighting effects.

- Select appropriate controllers (e.g., dimmer switches, RGB controllers, or DMX systems) for your desired level of control and automation.

Installation Tips for Flexible LED Strips on Curved Surfaces

Surface Preparation

Proper surface preparation is crucial for a successful installation of flexible LED strips on curved surfaces:

- Clean the surface thoroughly to remove dust, grease, or debris.

- For porous surfaces, consider applying a primer or sealant to improve adhesion.

- If using aluminum channels or profiles, ensure they are properly shaped to match the curve of the surface.

Mounting Techniques

Choose the appropriate mounting method based on the surface material and curvature:

- Adhesive backing: Most flexible LED strips come with a 3M adhesive backing suitable for smooth surfaces.

- Mounting clips: Use clips for additional support, especially on vertical or overhead curved surfaces.

- Aluminum channels: These provide protection and heat dissipation while allowing for a cleaner installation on curved surfaces.

- Silicone sleeves: For outdoor or wet environments, consider using waterproof silicone sleeves to protect the strip.

Wiring and Power Distribution

Proper wiring and power distribution are essential for optimal performance:

- Calculate the total power consumption and choose an appropriate power supply.

- For long curved runs, use parallel wiring or multiple power injection points to prevent voltage drop.

- Use flexible wire connections between strip segments to maintain a smooth curve.

- Ensure all connections are secure and properly insulated, especially in damp or outdoor environments.

Testing and Troubleshooting

Before finalizing the installation:

- Test the LED strip in sections to ensure all LEDs are functioning correctly.

- Check for any dark spots or uneven lighting along the curve.

- Verify that the strip adheres properly to the surface without lifting or sagging.

- Address any issues promptly, such as replacing faulty sections or reinforcing adhesion where needed.

Conclusion

Choosing the right flexible LED strip for curved surfaces involves careful consideration of factors such as bend radius, LED density, environmental protection, and installation requirements. By selecting high-quality strips and following proper installation techniques, you can achieve stunning lighting effects that enhance the visual appeal of any curved surface. Whether you're illuminating architectural features, creating ambient lighting in retail spaces, or adding accents to home decor, flexible LED strips offer a versatile and efficient lighting solution.

For expert guidance on selecting the perfect flexible LED strip for your curved surface project, or to explore custom lighting solutions tailored to your specific needs, don't hesitate to reach out to our team of lighting professionals. Contact us at Linda@uc-led.com to discuss your project requirements and discover how our innovative LED lighting solutions can bring your vision to life.