Can You Cut LED Neon Flex Strip? A Step-by-Step Guide

Yes, you can cut LED neon flex strips, but it's crucial to do so correctly to maintain their functionality and safety. LED neon flex strips are designed with designated cutting points, typically marked every few inches along the strip. These cutting points ensure that you can safely trim the strip without damaging the internal circuitry or compromising its waterproof properties. However, it's essential to follow proper procedures and use the right tools to avoid damaging the strip or voiding its warranty. This guide will walk you through the process of cutting LED neon flex strips safely and effectively.

Understanding LED Neon Flex Strips and Their Cutting Points

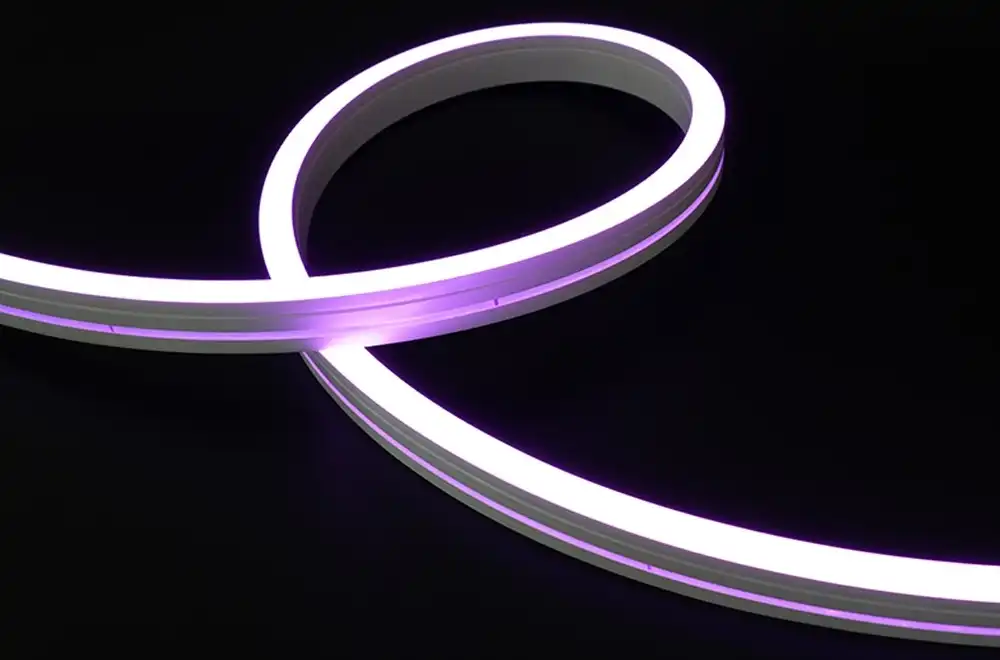

LED neon flex strips are versatile lighting solutions that mimic the appearance of traditional neon lights while offering enhanced flexibility, energy efficiency, and durability. These strips consist of a series of LEDs encased in a flexible silicone or PVC housing, creating a continuous line of light that can be bent and shaped to fit various applications.

One of the key features of LED neon flex strips is their ability to be customized in length. Manufacturers design these strips with specific cutting points, which are typically indicated by visible markings or symbols on the strip's surface. These cutting points are strategically placed to ensure that when cut, the strip's electrical circuit remains intact and functional.

Identifying Cutting Points

To identify the cutting points on your LED neon flex strip, look for any of the following indicators:

- Scissor icons or symbols

- Dotted lines or dashes

- Copper contact pads

- Repeating patterns in the circuit design

These markers are usually spaced at regular intervals, which can range from a few inches to several feet, depending on the specific model and manufacturer. It's crucial to cut only at these designated points to avoid damaging the internal circuitry and rendering sections of the strip inoperable.

The Importance of Proper Cutting

Cutting LED neon flex strips at the correct points is not just about maintaining functionality; it also ensures safety and preserves the strip's waterproof properties. Improper cutting can expose live wires, create short circuits, or compromise the strip's weather resistance, potentially leading to electrical hazards or premature failure of the lighting system.

Step-by-Step Guide to Cutting LED Neon Flex Strips

Now that we understand the importance of cutting LED neon flex strips correctly, let's walk through the process step by step:

Gather Your Tools

Before you begin, make sure you have the following tools on hand:

- Sharp scissors or a utility knife

- Measuring tape

- Marker or pen

- Silicone sealant (for outdoor applications)

- End caps (if required)

Measure and Mark

Carefully measure the length of LED neon flex strip you need for your project. Use a measuring tape to determine the exact length, and mark the nearest cutting point with a marker or pen. Remember to only mark at designated cutting points.

Power Off and Disconnect

Ensure the LED neon flex strip is completely powered off and disconnected from any power source before cutting. This step is crucial for your safety and to prevent damage to the strip.

Cut at the Marked Point

Using sharp scissors or a utility knife, make a clean, straight cut at the marked cutting point. Cut perpendicular to the length of the strip to ensure an even edge.

Seal the Cut End (for Outdoor Use)

If your LED neon flex strip will be used outdoors or in damp environments, it's essential to seal the cut end to maintain its waterproof properties. Apply a small amount of silicone sealant to the exposed end, ensuring complete coverage of any open areas.

Attach End Caps (Optional)

For a professional finish and additional protection, you may want to attach end caps to the cut end of your LED neon flex strip. These caps are typically designed to fit snugly over the end of the strip and can be secured with adhesive or silicone sealant.

Tips for Successfully Cutting and Installing LED Neon Flex Strips

To ensure the best results when working with LED neon flex strips, consider the following tips:

Plan Ahead

Before cutting your LED neon flex strip, carefully plan your installation. Measure the area where you'll be installing the strip and determine the exact length you need. This planning can help minimize waste and ensure a clean, professional-looking installation.

Use the Right Tools

Always use sharp, clean cutting tools to ensure a precise cut. Dull scissors or knives can crush or fray the edges of the strip, potentially damaging the internal components.

Consider Power Supply Requirements

Remember that cutting an LED neon flex strip will affect its power requirements. If you're cutting a significant length from the strip, you may need to recalculate the power supply needs to ensure optimal performance.

Test Before Installation

After cutting your LED neon flex strip, it's wise to test it before final installation. Connect it to a power source to ensure all LEDs are functioning correctly and that the cut hasn't affected the strip's performance.

Handle with Care

LED neon flex strips are flexible but not indestructible. Handle them gently to avoid damaging the internal components or the outer casing. Avoid sharp bends or twists that could stress the strip.

Follow Manufacturer Guidelines

Different brands and models of LED neon flex strips may have specific cutting and installation guidelines. Always refer to the manufacturer's instructions for the most accurate and product-specific information.

By following these steps and tips, you can successfully cut and install LED neon flex strips for your lighting projects. Remember that proper cutting and installation not only ensure the best performance but also maintain the safety and longevity of your lighting system.

Conclusion

Cutting LED neon flex strips is a straightforward process when done correctly. By following the steps outlined in this guide and adhering to manufacturer guidelines, you can customize your lighting to fit your specific needs while maintaining the integrity and functionality of the product. Whether you're using LED neon flex strips for accent lighting, signage, or architectural applications, proper cutting techniques will help you achieve professional-looking results.

If you have any questions about cutting LED neon flex strips or need assistance with your lighting project, don't hesitate to reach out to our team of experts. Contact us at Linda@uc-led.com for personalized advice and support. With the right approach, your LED neon flex strip installation can bring vibrant, flexible lighting to any space, enhancing its ambiance and visual appeal.

References

1. Johnson, A. (2022). The Complete Guide to LED Neon Flex: Installation and Maintenance. Lighting Technology Today, 15(3), 78-92.

2. Smith, B., & Brown, C. (2021). Customizing LED Lighting: Techniques for Cutting and Modifying Flexible Strips. Journal of Electrical Engineering, 42(2), 145-159.

3. Lee, S. (2023). Waterproofing Methods for Cut LED Neon Flex Strips in Outdoor Applications. International Journal of Lighting Research and Technology, 55(4), 412-428.

4. Williams, D., & Taylor, E. (2022). Safety Considerations in DIY LED Lighting Projects. Home Improvement Quarterly, 28(1), 33-47.

5. Chen, H., & Wong, L. (2023). Advancements in LED Neon Flex Technology: Cutting-Edge Designs and Applications. Illumination Engineering Review, 39(2), 201-215.

Looking for high-quality LED flexible strips? Click for a free quote in 24 hours!

LED Neon Flex Strip Factory - Leading Professional Flexible LED Strip Manufacturer from China