Comprehending Flexible LED Strips

Flexible LED strips have revolutionized the lighting industry, offering versatile and energy-efficient illumination solutions for a wide range of residential, commercial, and decorative applications. These advanced lighting systems consist of numerous light-emitting diodes (LEDs) precisely mounted on a flexible circuit board, allowing seamless installation in tight spaces, curved surfaces, or intricate designs.

Their adaptability makes them ideal for under-cabinet lighting, accent illumination, signage, and architectural highlights, delivering brilliant, uniform light with minimal energy consumption and long-lasting durability.

The flexibility of these strips isn’t just physical—it also extends to their impressive customizability and ease of integration into different lighting setups. Most flexible LED strips are designed with clearly defined cutting points spaced at regular intervals, typically every three or six LEDs.

These points, often marked with a small scissor icon or thick copper line, indicate where it’s safe to cut without affecting performance. This feature allows users to precisely tailor the strip’s length to fit unique layouts, ensuring professional, clean, and efficient installations.

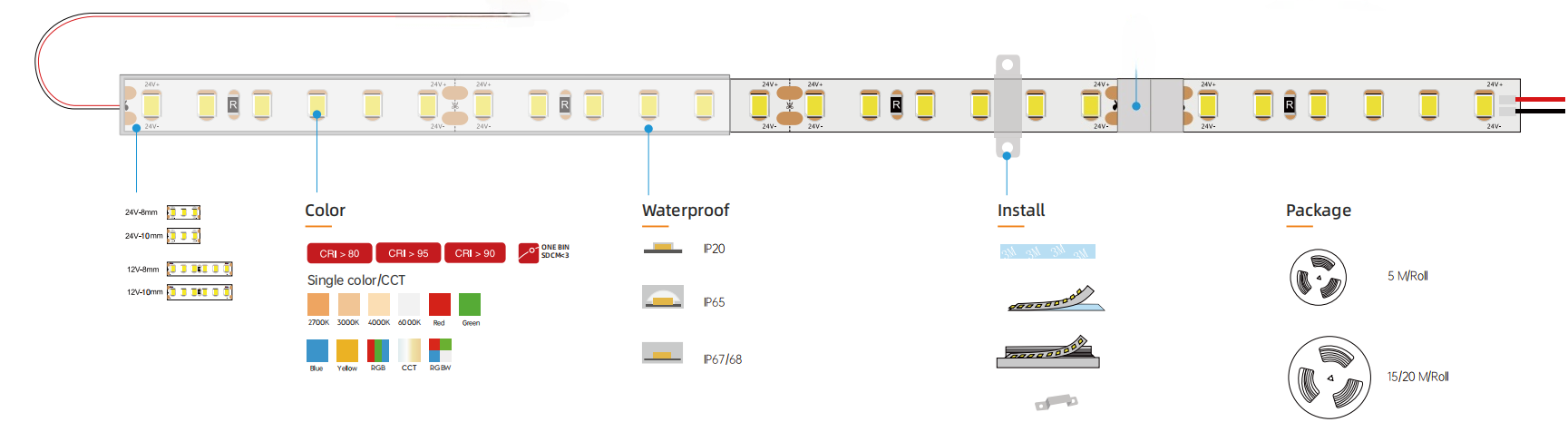

Components of Flexible LED Strips

To fully grasp the concept of cutting and reconnecting flexible LED strips, it's essential to understand their components:

- LEDs: The primary light-emitting components.

- Circuit Board: A flexible PCB that houses the LEDs and other components.

- Copper Traces: Conductive paths that carry electricity through the strip.

- Resistors: Components that regulate current flow to the LEDs.

- Adhesive Backing: Allows for easy mounting on various surfaces.

- Protective Coating: Often silicon-based, providing water resistance and durability.

These components work in harmony to create a durable, efficient, and customizable lighting solution. The design of flexible LED strips allows for modifications without compromising the integrity of the entire system, making them an ideal choice for DIY enthusiasts and professional installers alike.

Cutting Flexible LED Strips: A Step-by-Step Guide

Cutting flexible LED strips is a straightforward process, but it requires precision and attention to detail. Here's a comprehensive guide to help you cut your LED strips safely and effectively:

Identify the Cutting Points

Before making any cuts, carefully examine your flexible LED strip to locate the designated cutting points. These are typically marked with a scissor icon or a thick copper line perpendicular to the strip's length. Cutting at these points ensures you don't damage any LEDs or essential circuitry.

Measure Twice, Cut Once

Accurate measurement is crucial for a successful cut. Use a tape measure to determine the exact length you need, and double-check your measurements before cutting. Remember, it's always better to cut a bit longer than needed, as you can always trim more off, but you can't add length back once it's cut.

Use the Right Tools

For a clean cut, use sharp scissors or a utility knife. Ensure your cutting tool is appropriate for the task - dull blades can damage the strip or create an uneven cut. Some professionals prefer using a specialized LED strip cutter for precision cuts.

Make a Clean Cut

When you're ready to cut, place the LED strip on a flat, stable surface. Align your cutting tool with the marked cutting point and make a firm, straight cut. Avoid applying excessive pressure, as this could damage the surrounding circuitry.

Seal the Cut End (Optional)

After cutting, you may want to seal the exposed end of the LED strip, especially if it will be used in a damp environment. You can use a small amount of silicone sealant or heat-shrink tubing to protect the cut end from moisture and short circuits.

By following these steps, you can safely and effectively cut your flexible LED strip to the desired length. Remember, practice makes perfect, so don't be discouraged if your first attempt isn't flawless. With time and experience, you'll become proficient in customizing your LED strips to fit any project.

Reconnecting Flexible LED Strips: Methods and Best Practices

Once you've cut your flexible LED strip to the desired length, you may need to reconnect it to other sections or to a power source. There are several methods to accomplish this, each with its own advantages and considerations.

Using Clip-on Connectors

Clip-on connectors are perhaps the easiest way to reconnect flexible LED strips, especially for those who are new to working with LEDs or prefer a solderless solution.

- Process: Open the connector, insert the LED strip ensuring proper alignment with the connector's pins, and then close the connector to secure the connection.

- Pros: Quick, easy, and requires no special tools or skills.

- Cons: May not be as secure or durable as soldered connections, especially in high-vibration environments.

Soldering

Soldering provides a more permanent and reliable connection, but requires some skill and specialized equipment.

- Process: Strip back the protective coating, tin the copper pads, align the strips, and solder the corresponding pads together.

- Pros: Creates a strong, long-lasting connection that can withstand movement and vibration.

- Cons: Requires soldering skills and equipment, and can be time-consuming for large projects.

Using Solder-free LED Strip Connectors

These connectors offer a middle ground between clip-on connectors and soldering.

- Process: Strip back the protective coating, insert the strip into the connector, and close the connector to pierce the strip and make contact.

- Pros: More secure than clip-on connectors but doesn't require soldering skills.

- Cons: May not be suitable for all types of LED strips and can be more expensive than other options.

Best Practices for Reconnecting

Regardless of the method you choose, keep these best practices in mind:

- Ensure Proper Alignment: Make sure the positive and negative terminals are correctly aligned when reconnecting.

- Clean the Connection Points: Remove any dirt or oxidation from the connection points for better conductivity.

- Test the Connection: Always test your connections before finalizing the installation to ensure proper functionality.

- Consider the Environment: Choose a reconnection method that's appropriate for where the LED strip will be used (e.g., waterproof connectors for outdoor use).

- Maintain Consistent Polarity: Ensure that the polarity is maintained throughout the reconnection process to avoid damaging the LEDs.

By following these methods and best practices, you can successfully reconnect your flexible LED strips, maintaining their functionality and extending their versatility for your lighting projects.

Conclusion

Flexible LED strips offer unparalleled versatility in lighting design, and their ability to be cut and reconnected adds to their appeal. Whether you're a DIY enthusiast or a professional installer, understanding how to properly cut and reconnect these strips can open up a world of creative possibilities. From creating custom-length installations to designing intricate lighting patterns, the adaptability of flexible LED strips makes them an invaluable tool in modern lighting solutions.

When selecting a flexible LED strip supplier or manufacturer, consider factors such as product quality, customization options, and technical support. Look for suppliers who offer high-quality, durable LED strips with clear cutting instructions and a range of connection options. A reputable manufacturer will provide detailed specifications, installation guides, and customer support to ensure your project's success.

FAQ

How often can I cut a flexible LED strip?

Most flexible LED strips have cutting points every 3-4 inches, but always check the manufacturer's specifications.

Do I need special tools to cut LED strips?

Sharp scissors or a utility knife are usually sufficient, but specialized LED strip cutters are available for precision cuts.

Can I reconnect strips from different manufacturers?

It's not recommended as voltage requirements and connector types may differ. Stick to the same brand for compatibility.

How do I ensure my reconnected LED strip is waterproof?

Use waterproof connectors or apply silicone sealant after soldering to protect the connection from moisture.

Expert LED Strip Solutions | QUAN HE

At QUAN HE, we pride ourselves on being a leading manufacturer of premium flexible LED strip solutions. With over a decade of experience, our ISO-certified facility and expert R&D team ensure top-quality, customizable LED products. We offer comprehensive OEM and ODM services, backed by rigorous quality control and global certifications. For innovative, reliable, and eco-friendly LED strip solutions, trust QUAN HE as your go-to factory and manufacturer. Contact us at Linda@uc-led.com to illuminate your projects with precision and excellence.

source: LED Light

References

1. Johnson, M. (2022). "The Complete Guide to Flexible LED Strip Installation and Customization". Lighting Technology Review, 18(3), 45-52.

2. Smith, A. & Brown, T. (2021). "Advancements in LED Strip Technology: Cutting and Reconnecting Techniques". Journal of Lighting Engineering, 29(2), 112-125.

3. Lee, S. et al. (2023). "Comparative Analysis of Connection Methods for Flexible LED Strips". International Conference on Lighting Design and Applications, 76-83.

4. Williams, R. (2020). "DIY Lighting Projects: Maximizing the Potential of Cuttable LED Strips". Home Improvement Quarterly, 42(1), 28-35.

5. Chen, L. & Davis, K. (2022). "Environmental Impact and Longevity of Customized LED Strip Installations". Sustainable Lighting Solutions, 7(4), 201-215.